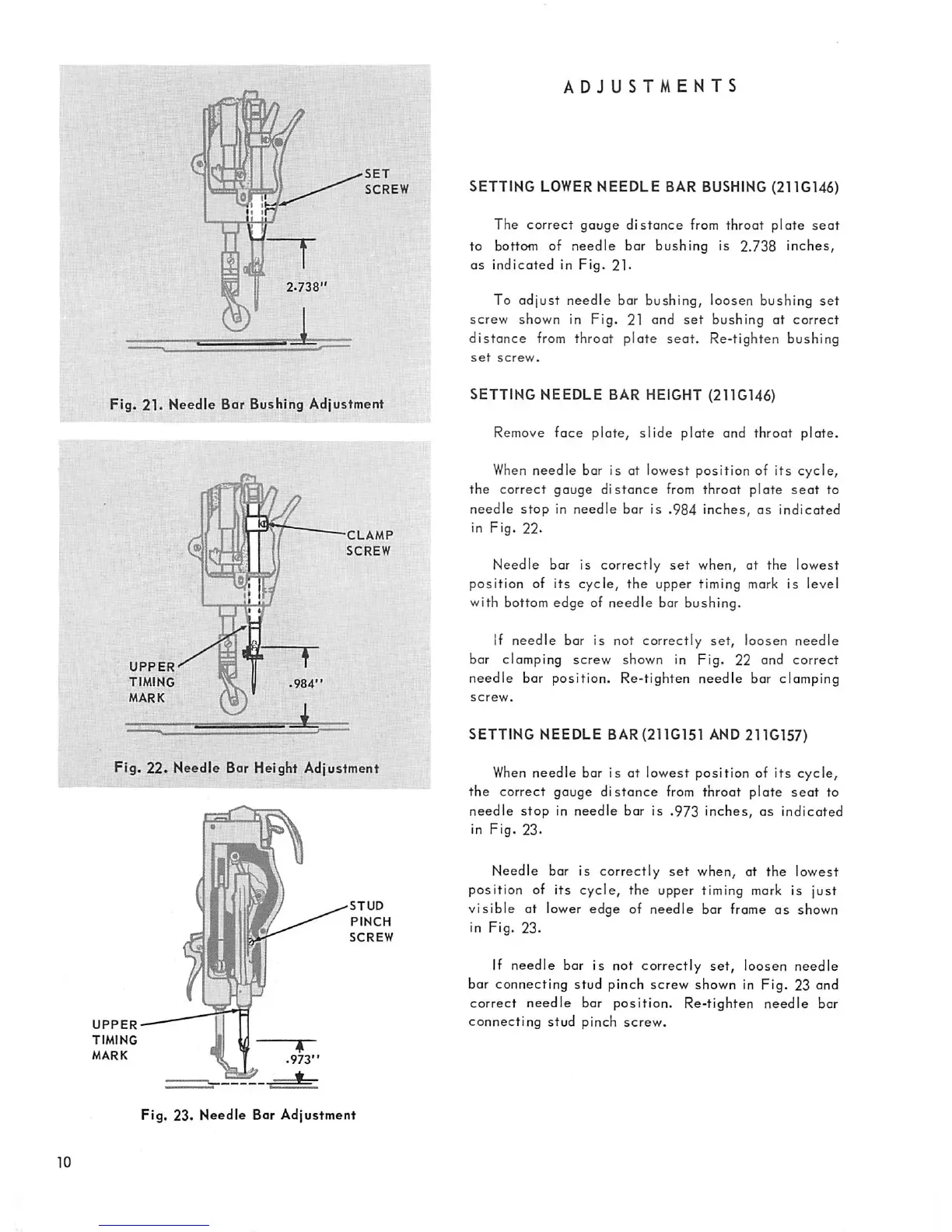

2.738"

SET

SCREW

Fig. 21. Needle Bar Bushing Adjustment

UPPER

TIMING

MARK

CLAMP

SCREW

Fig.

22.

Needle Bar Height Adjustment

UPPER

TIMING

MARK

STUD

PINCH

SCREW

Fig.

23.

Needle

Bar

Adjustment

ADJUSTMENTS

SETTING LOWER

NEEDLE

BAR BUSHING (211G146)

The

correct

gauge

distance

from

throat

plate

seat

to bottom of needle bar bushing is 2.738 inches,

as indicated in Fig. 21.

To

adiust

needle

bar bushing, loosen bushing

set

screw

shown in

Fig.

21 and

set

bushing

at

correct

distance

from

throat plate

seat.

Re-tighten bushing

set

screw.

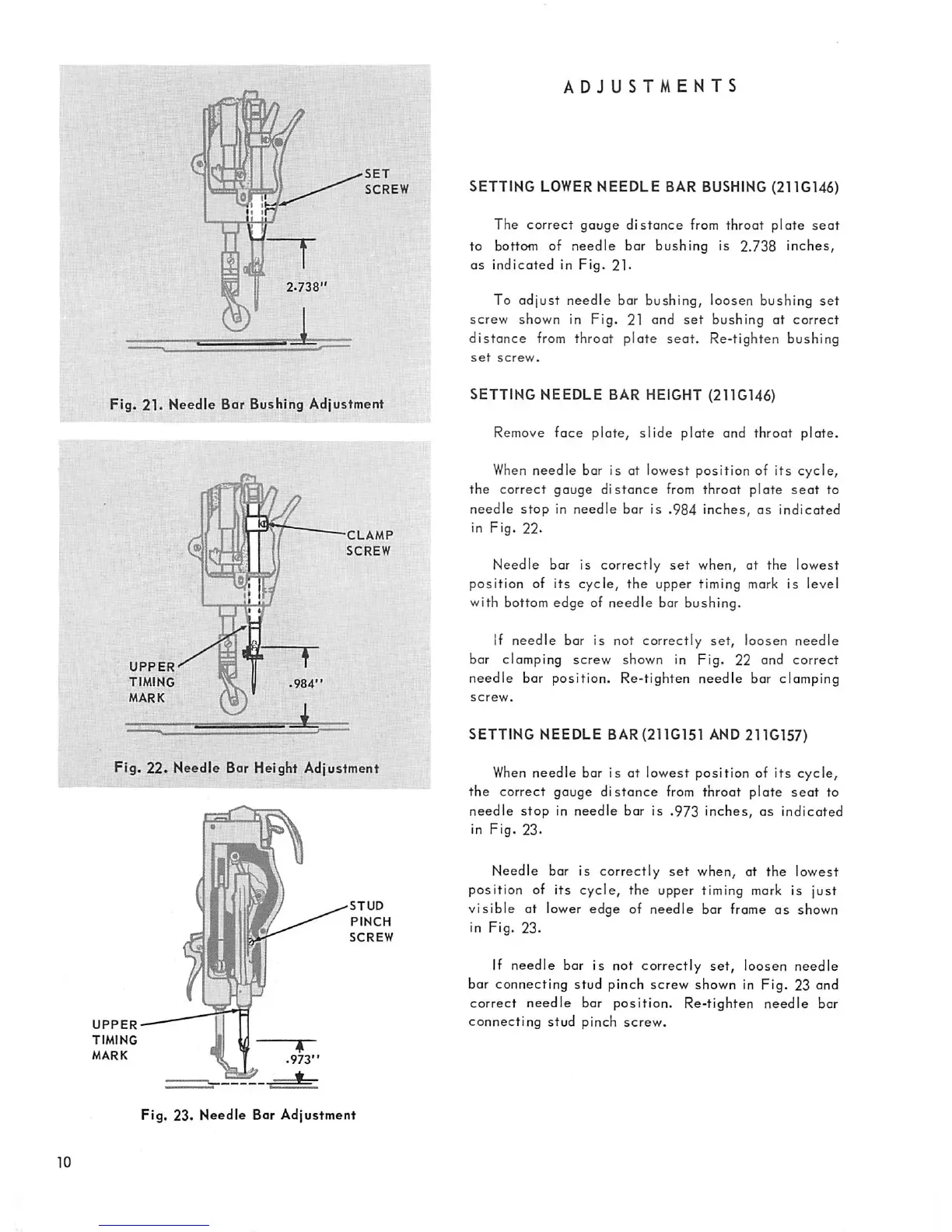

SETTING NEEDLE BAR HEIGHT (211G146)

Remove face plate,

slide

plate

and throat plate.

When

needle bar is at lowest position of

its

cycle,

the

correct

gauge

distance

from

throat

plate

seat

to

needle

stop

in needle bar is .984 inches, as indicated

in Fig. 22.

Needle bar is

correctly

set

when, at the lowest

position of its

cycle,

the

upper timing mark is level

with bottom edge of

needle

bar bushing.

If

needle

bar is not correctly

set,

loosen needle

bar clamping screw shown in Fig. 22 and correct

needle bar position. Re-tighten needle bar clamping

SETTING NEEDLE BAR(211G151 AND 211G157)

When

needle bar is at lowest position of

its

cycle,

the correct gauge

distance

from throat plate

seat

to

needle

stop

in

needle

bar is

.973

inches,

as

indicated

in

Fig.

23.

Needle bar is correctly

set

when, at the lowest

position of its cycle, the upper timing

mark

is just

visible

at lower edge of needle bar frame

as

shown

in Fig. 23.

If needle bar Is not correctly set, loosen needle

bar connecting stud pinch screw shown in Fig. 23 and

correct

needle

bar position. Re-tighten

needle

bar

connecting

stud

pinch

screw.

Loading...

Loading...