I LOWER TIMING

,1

MARK

BOBBIN

CASE

STOP

FINGER

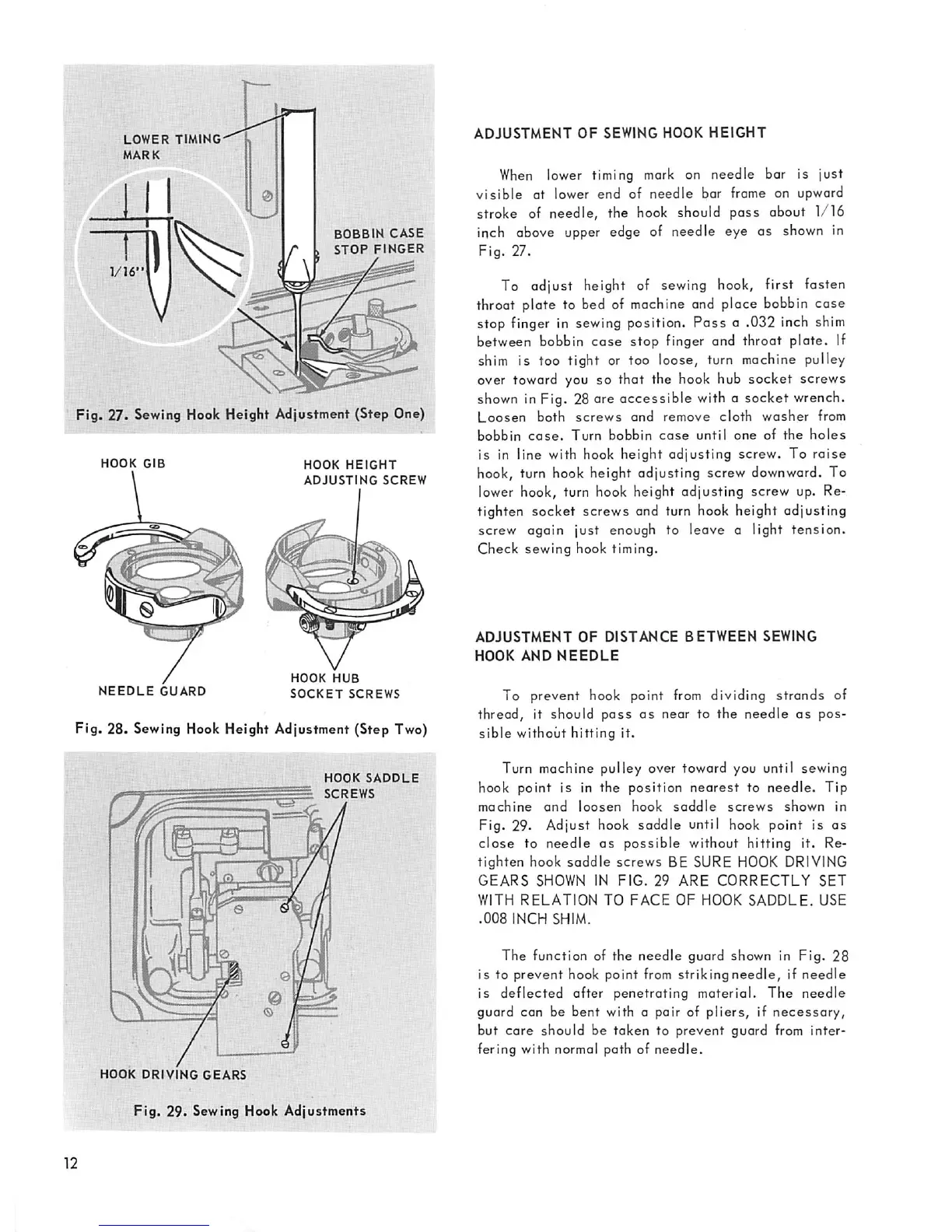

Fig. 27. Sewing Hook Height Adjustment (Step One)

HOOK

GIB

NEEDLE

GUARD

HOOK

HEIGHT

ADJUSTING

SCREW

HOOK

HUB

SOCKET

SCREWS

Fig.

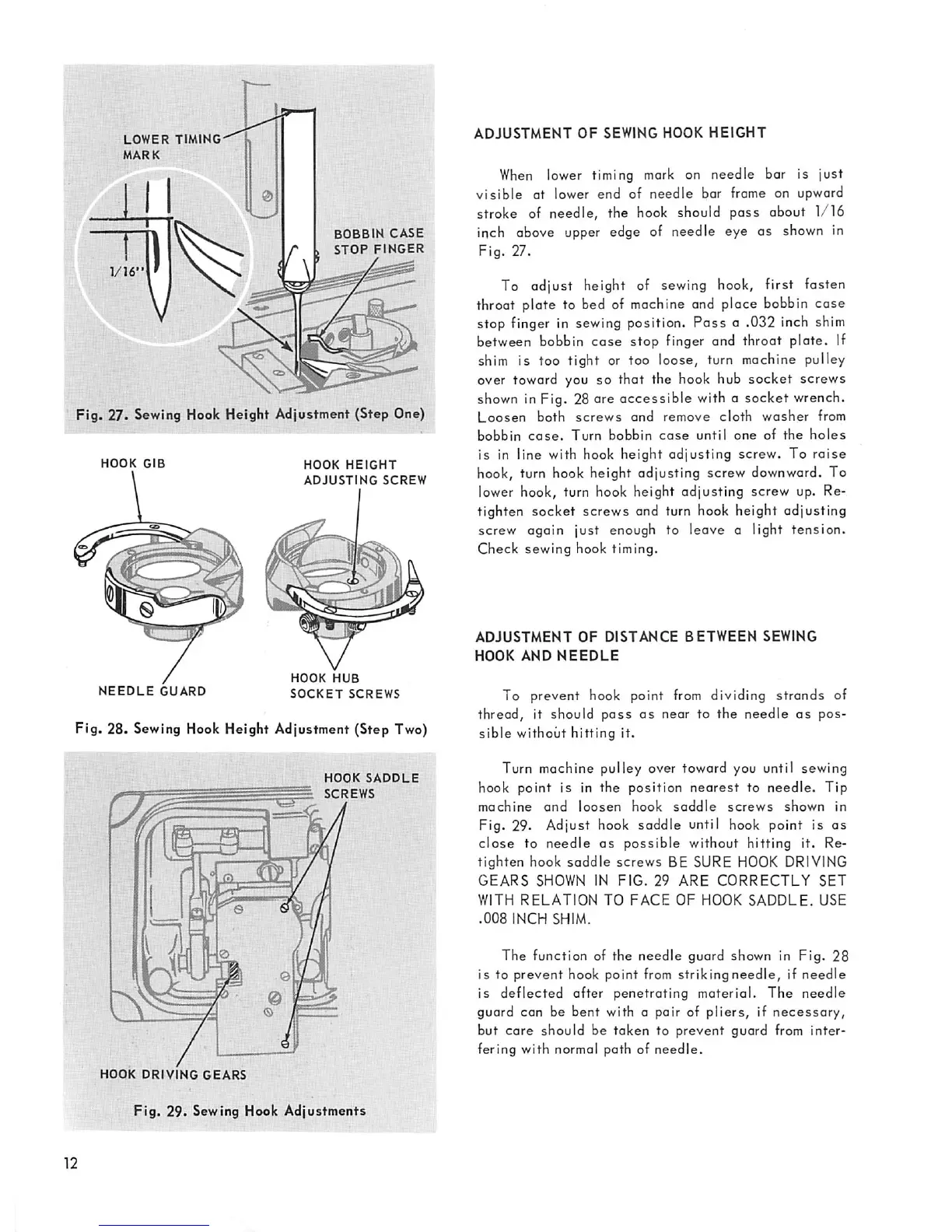

28. Sewing Hook Height Adjustment (Step Two)

HOOK

DRIVING

GEARS

HOOK

SADDLE

SCREWS

Fig.

29. Sewing Hook Adjustments

ADJUSTMENT

OF

SEWING

HOOK

HEIGHT

When

lower timing mark on needle bar is just

visible

at lower end of needle bar frame on upword

stroke of needle, the

hook

should pass about 1/16

inch above upper edge of needle eye as shown in

Fig.

27.

To adiust height of sewing hook, first fasten

throat plate to bed of machine and place bobbin

case

stop finger in sewing position.

Pass

a .032 inch shim

between bobbin case stop finger and throat plate. If

shim is too tight or too loose, turn machine pulley

over toward you so that the hook hub socket screws

shown

in Fig. 28 are accessible with a socket

wrench.

Loosen

both

screws

and

remove

cloth

washer

from

bobbin

case.

Turn

bobbin

case

until

one

of

the

holes

is in line with hook height adjusting screw. To

raise

hook, turn hook height adjusting screw downward. To

lower hook, turn hook height adjusting screw up. Re-

tighten socket screws and turn hook height adjusting

screw again just enough to leave a light tension.

Check sewing hook timing.

ADJUSTMENT

OF

DISTANCE

BETWEEN

SEWING

HOOK

AND

NEEDLE

To prevent hook point

from

dividing strands of

thread, it should

pass

as

near to the

needle

as

pos

sible

without hitting it.

Turn machine pulley over toward you until sewing

hook

point

is in

the

position

nearest

to

needle.

Tip

machine

and

loosen

hook

saddle

screws

shown

in

Fig. 29. Adjust hook saddle until hook point is as

close

to

needle

as

possible

without

hitting

it. Re-

tighten hook

saddle

screws BE SURE

HOOK

DRIVING

GEARS

SHOWN

IN

FIG.

29

ARE

CORRECTLY

SET

WITH

RELATION

TO

FACE

OF

HOOK

SADDLE.

USE

.008

INCH

SHIM.

The

function of the

needle

guard shown in

Fig.

28

is to prevent hook point from striking

needle,

if

needle

is

deflected

after penetrating material. The needle

guard

can be bent with a pair of

pliers,

if

necessary,

but

care

should be

taken

to prevent guard from inter

fering with normal path of

needle.

Loading...

Loading...