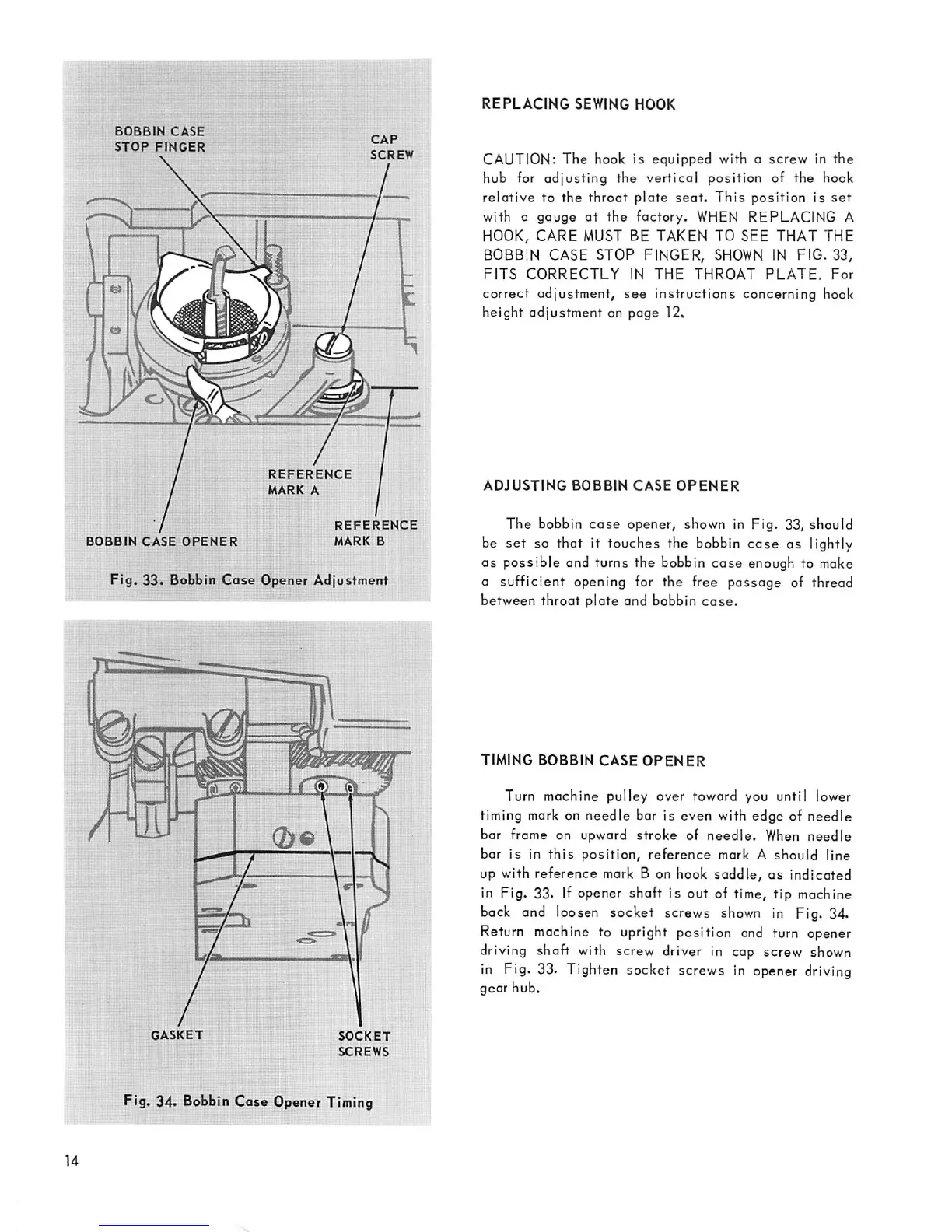

BOBBIN

CASE

STOP

FINGER

BOBBIN

CASE

OPENER

REFERENCE

MARK

A

CAP

SCREW

REFERENCE

MARK

B

Fig.

33.

Bobbin

Case

Opener

Adjustment

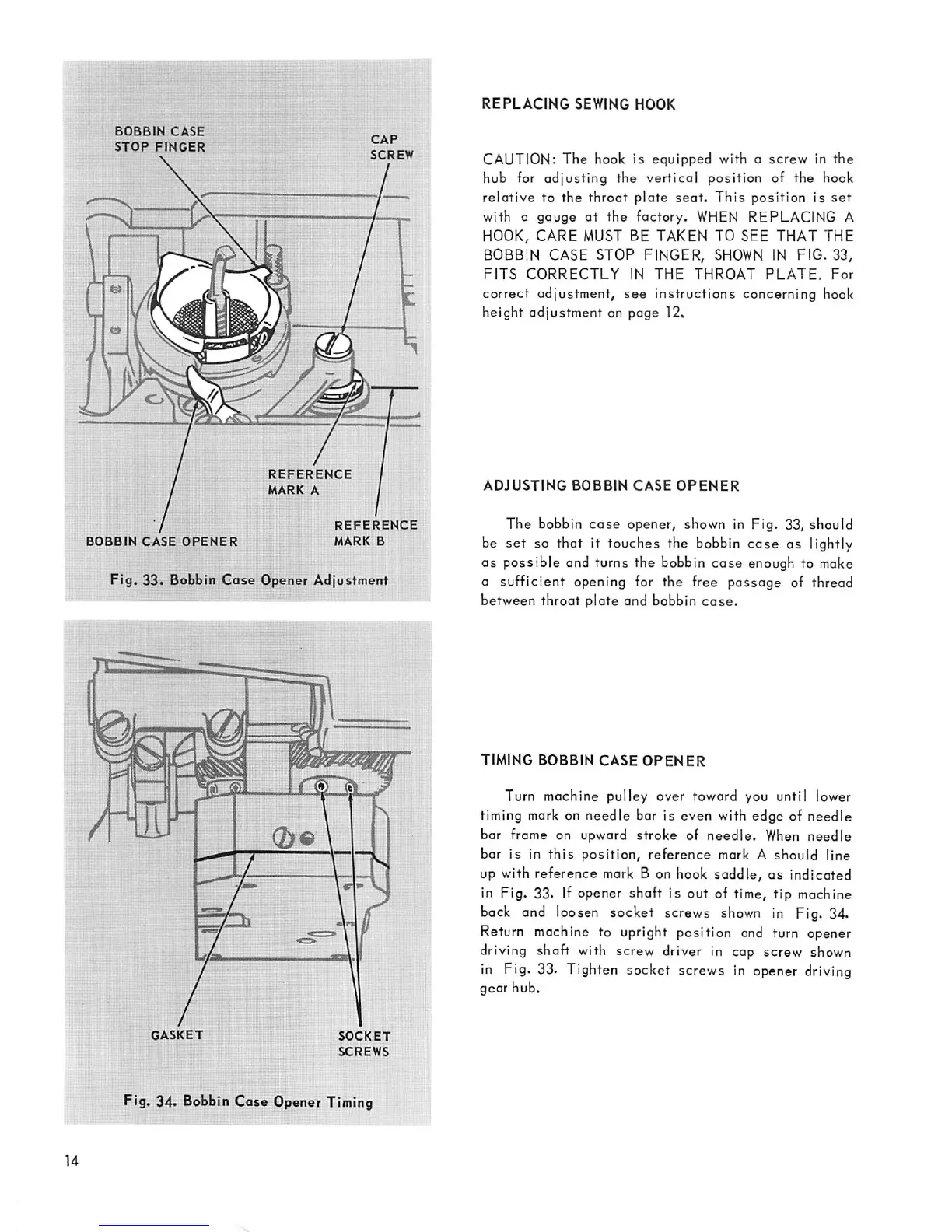

GASKET

SOCKET

SCREWS

Fig. 34. Bobbin Case Opener Timing

REPLACING

SEWING

HOOK

CAUTION: The hook is equipped with a screw in the

hub for

adjusting

the

vertical

position of the hook

relative

to

the

throat plate

seat.

This

position is

set

with a gouge at

the

factory.

WHEN

REPLACING A

HOOK, CARE MUST BE TAKEN TO SEE THAT THE

BOBBIN CASE STOP FINGER,

SHOWN

IN FIG. 33,

FITS

CORRECTLY

IN

THE

THROAT

PLATE.

For

correct adjustment,

see

instructions

concerning hook

height adjustment on page 12.

ADJUSTING

BOBBIN

CASE

OPENER

The

bobbin

case

opener,

shown in

Fig.

33,

should

be

set

so that it touches the bobbin cose as lightly

as

possible

and turns the bobbin

cose

enough to moke

a

sufficient

opening for

the

free

passage

of thread

between

throat

plate

and bobbin

case.

TIMING

BOBBIN

CASE

OPENER

Turn machine pulley over toward you until lower

timing mark on needle bar is even with edge of needle

bar frame on upward stroke of

needle.

When

needle

bar

is

in

this

position,

reference

mark A

should

line

up with reference mark B on hook saddle, as indicated

in Fig. 33. If opener shaft is out of time, tip machine

back and loosen socket screws

shown

in Fig. 34.

Return machine to upright position and turn opener

driving shaft with screw driver in cap screw shown

in

Fig. 33. Tighten socket screws

in

opener

driving

gear

hub.

Loading...

Loading...