LOWER

THREADING

BOBBIN

REMOVAL

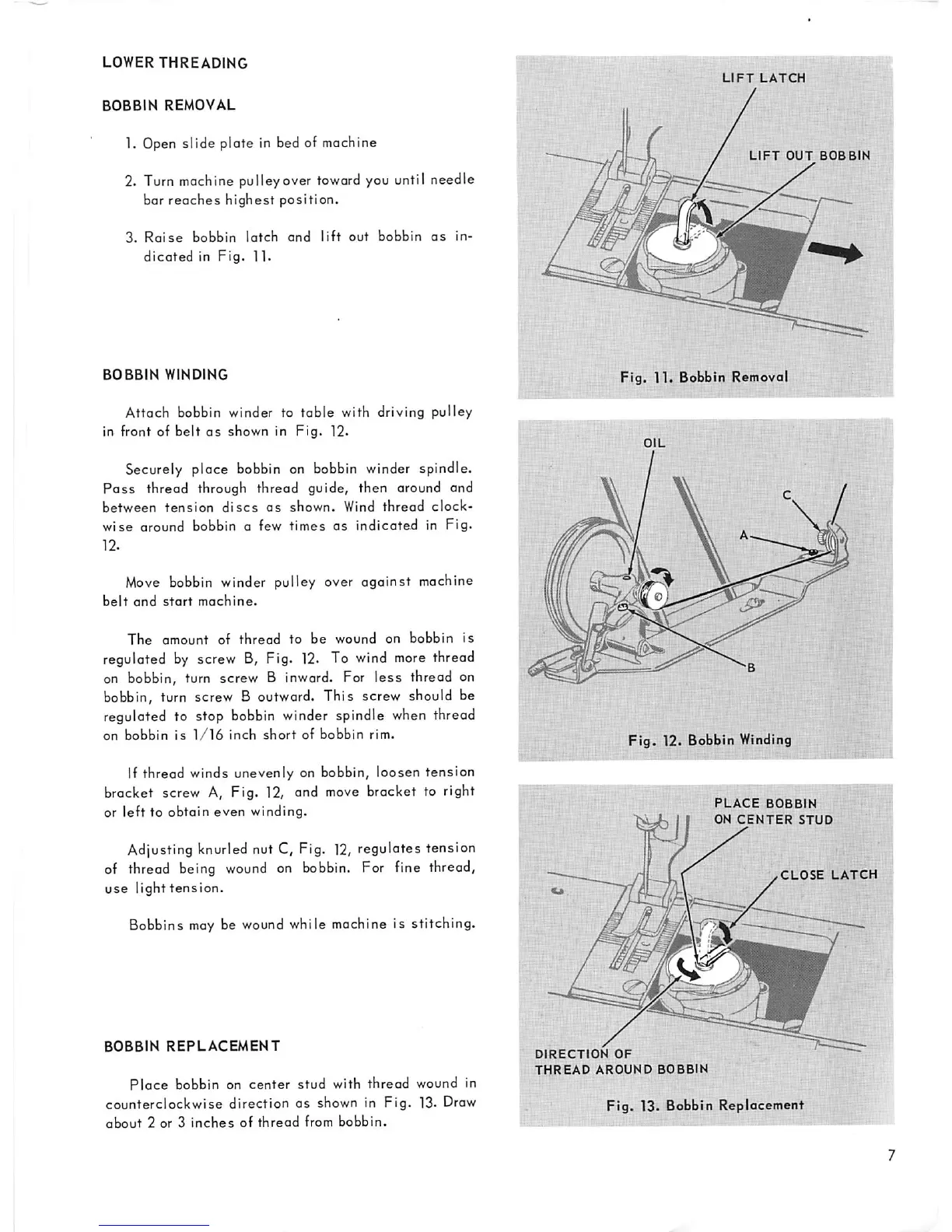

1. Open slide plate in bed of machine

2. Turn machine pulleyover toward you until needle

bar

reaches

highest

position.

3.

Raise

bobbin

latch

and

lift

out

bobbin

as

in

dicated

in

Fig.

11.

BOBBIN

WINDING

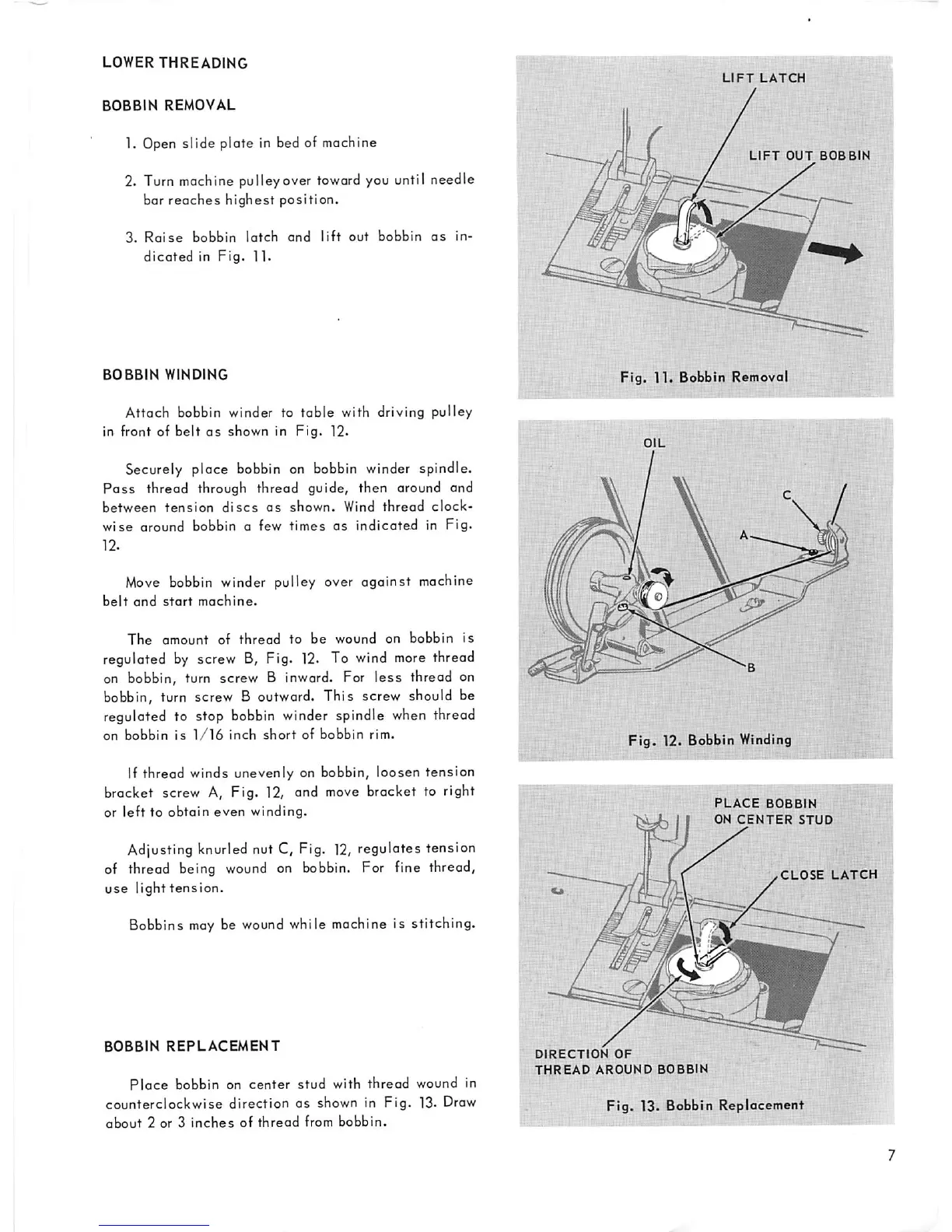

Attach bobbin winder to

table

with driving pulley

in front of

belt

as

shown

in

Fig.

12.

Securely place bobbin on bobbin winder spindle.

Pass

thread through thread guide, then around and

between

tension

discs

as

shown.

Wind

thread

clock

wise

around

bobbin a few

times

as

indicated

in

Fig.

12.

Move

bobbin winder pulley over against machine

belt

and

start

machine.

The

amount

of

thread

to

be

wound

on

bobbin

is

regulated

by

screw B, Fig.

12.

To

wind

more

thread

on bobbin, turn screw B inward. For

less

thread on

bobbin, turn screw B outward. This screw should be

regulated to stop bobbin winder spindle when thread

on

bobbin

is

1/16

inch

short

of

bobbin

rim.

If thread winds unevenly on bobbin, loosen tension

bracket screw A, Fig. 12, and

move

bracket to right

or

left

to

obtain

even

winding.

Adjusting knurled nut C, Fig.

12,

regulates tension

of thread being

wound

on

bobbin.

For fine thread,

use

light

tension.

Bobbins

may

be

wound

while machine is stitching.

BOBBIN

REPLACEMENT

Place

bobbin

on

center

stud

with

thread

wound in

counterclockwise

direction

as shown in

Fig.

13. Draw

about

2 or 3

inches

of

thread

from

bobbin.

Bpf''

LIFT

LATCH

LIFT

OUT

BOBBIN

Fig. 11. Bobbin Removal

Fig.

12. Bobbin Winding

PLACE

BOBBIN

ON

CENTER

STUD

CLOSE

LATCH

•

DIRECTION

OF

THREAD

AROUND

BOBBIN

Fig.

13. Bobbin Replacement

Loading...

Loading...