Singer

288

64

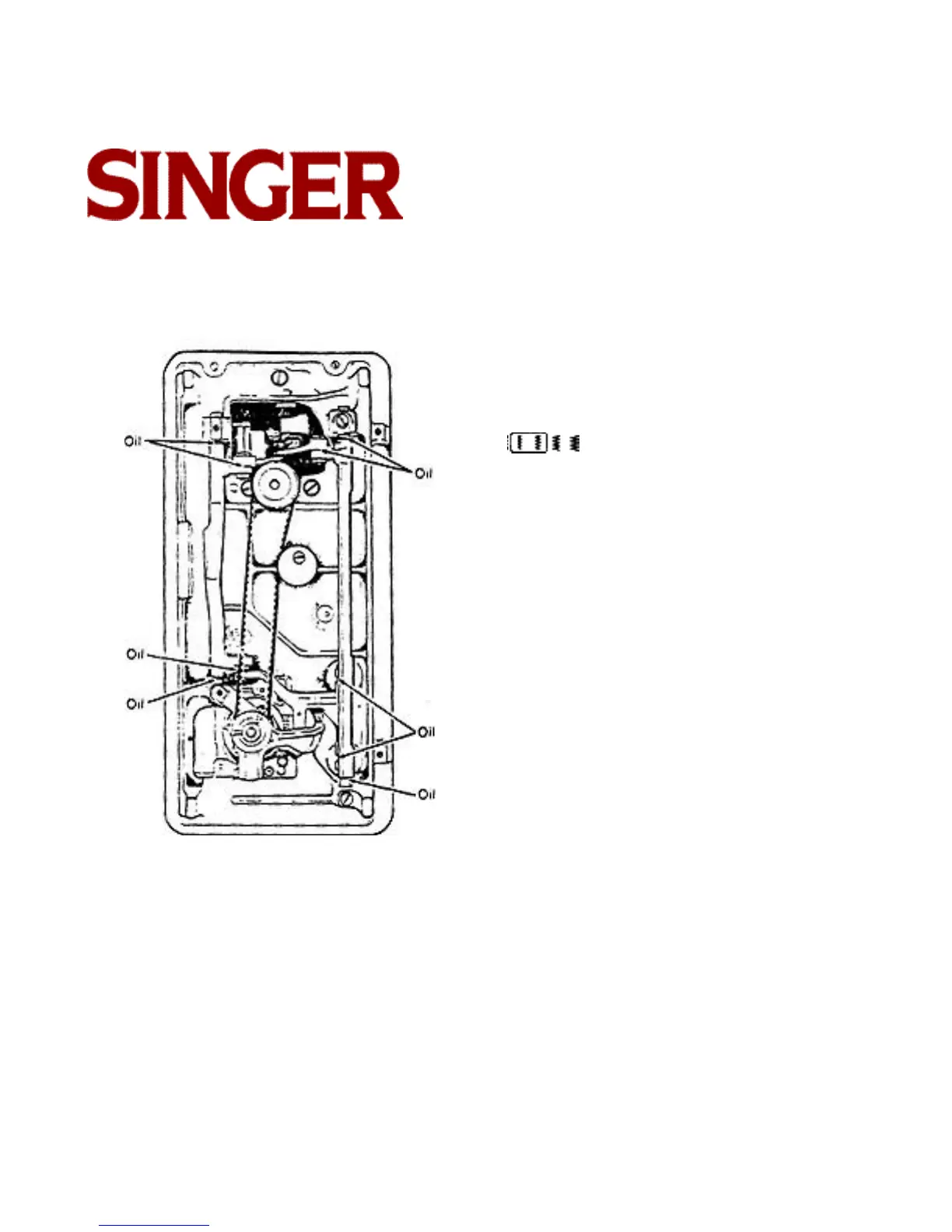

Lubricate bottom of machine

• Clean out lint and apply oil to each of the places

indicated.

IF MACHINE IS TO BE STORED

• Disconnect power-line plug from electric outlet.

• Clean all exposed parts and area behind face plate.

• Swab all exposed metal parts and parts behind face

plate with SINGER oil to protect against rust.

Hints for Home Service

If needle breaks, make sure. . .

• Needle is straight, correct style for machine and

proper size for thread being used.

• Needle is correctly inserted into machine.

• Stitch width and needle position selectors are cor-

rectly set for work being done.

• Stitch width setting does not exceed

( )setting when twin needle is used.

• Presser foot shank is securely fastened to presser

bar.

If needle thread breaks, make sure . . .

• Machine is threaded properly.

• Thread is unwinding freely from spool.

• Thread is free from slubs and knots.

• Needle is correct size for thread.

• Needle-thread tension is not too tight.

• Bobbin and bobbin case are properly inserted in

machine.

Remember to . . .

• Remove thread from bobbin before rewinding.

• Keep a pattern disc on disc holder at all times.

• Set combination stitch length and buttonhole dial for

regular stitching when not making buttonholes.

Loading...

Loading...