HRX-OM-Q026

Chapter 8 Documents

HRSH Series 8.1 Specifications

8-3

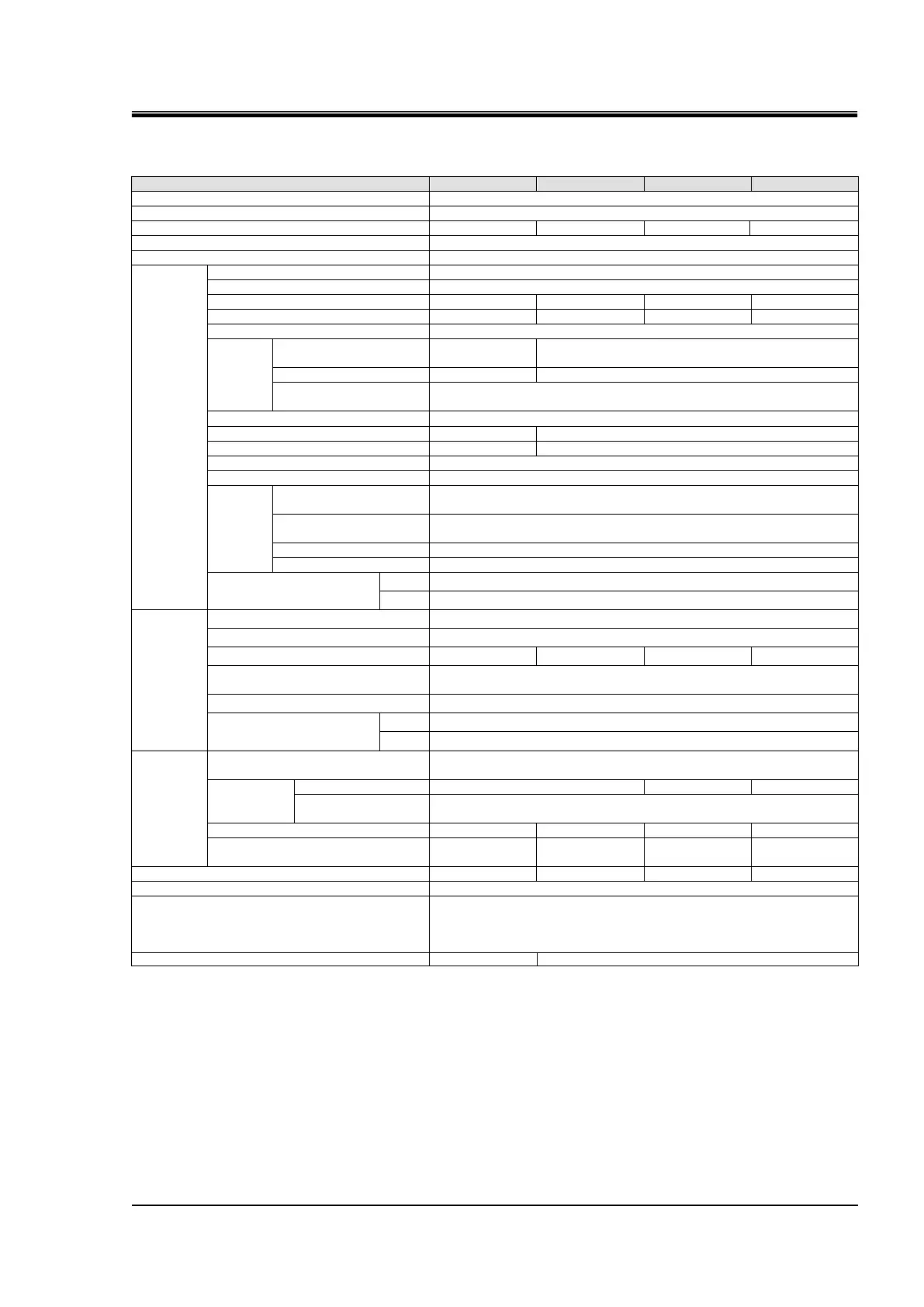

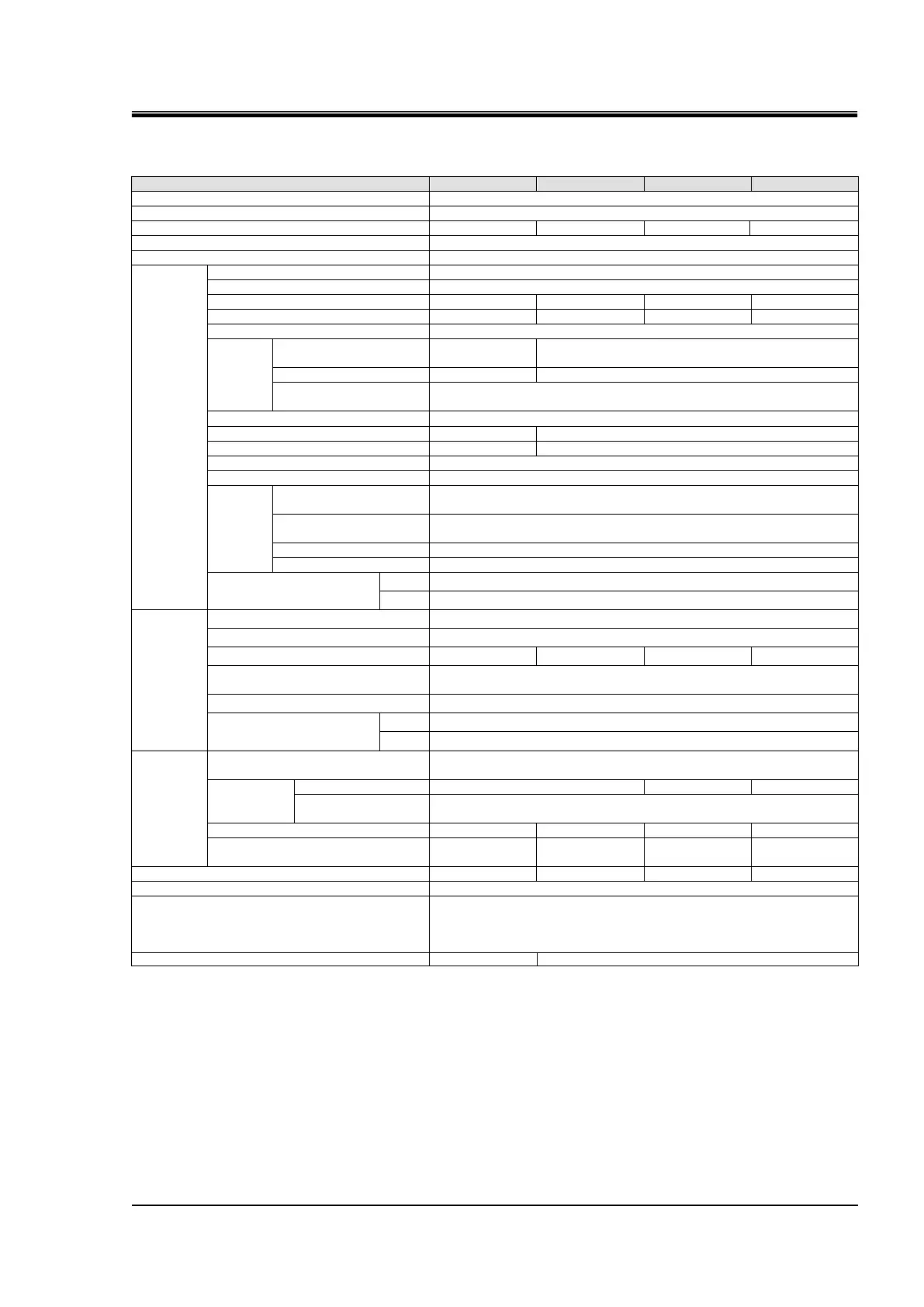

8.1.3 HRSH100/150/200/250-W-20-

Table 8-3 Specifications of HRSH100/150/200/250-W-20-

Water-cooled refrigeration

Clear water, 15% ethylene glycol aqueous solution, DI water (pure water)

Settable pressure range

6

Minimum necessary flow rate

7

Rc1 (Symbol F: G1, Symbol N: NPT1)

Rc3/4 (Symbol F: G3/4, Symbol N: NPT3/4)

Automatic

water fill

function

(Standard)

Supply side

pressure range

Supply side water

temp. range

Automatic water fill port size

Rc1/2 (Symbol F: G1/2, Symbol N: NPT1/2)

Rc1 (Symbol F: G1, Symbol N: NPT1)

Fluid contact part material

Stainless steel, Copper (Brazing filler metal for the heat exchanger), Bronze, Brass,

PTFE, PU, FKM, EPDM, PVC, NBR, POM, PE, NR

Inlet-outlet pressure differential of

facility water

Fluid contact part material

Stainless steel, Copper (Brazing filler metal for the heat exchanger), Bronze, Brass

3 phase 200 VAC (50 Hz), 3 phase 200 V to 230 VAC (60Hz)

Allowable voltage fluctuation +/- 10% (No continuous voltage fluctuation)

Applicable earth

leakage

breaker

8

Rated operating current

5

Rated power consumption

5

Noise level (Front: 1m, height: 1m)

5

Water-proof specification

Alarm code list label 2pcs. (English 1, Japanese 1),

Operation manual (for installation/operation) 2 copies (English 1, Japanese 1),

Y strainer (40 mesh) 25A, Barrel nipple 25A,

Anchor bracket 2 pcs. (including 6 pcs. of M8 bolts)

*9

Weight (in the dry state)

1: Use a 15% ethylene glycol aqueous solution if operating in a place where the ambient temperature or the circulating fluid temperature is 10 oC or less. When there is a

possibility of the facility water being frozen, make sure to discharge all the facility water from the facility water circuit.

2: Use fluid for circulating fluid that conforms to:

When there is a possibility of the facility water being frozen, make sure to discharge all the facility water from the facility water circuit.

Clean water: Water Quality Standards of the Japan Refrigeration and Air Conditioning Industrial Association (JRA GL-02-1994)

15 % ethylene glycol aqueous solution: Diluted with clean water, without any additives such as antiseptics.

DI water (pure water): Electrical conductivity 1 μS/cm or more (electrical resistivity 1MΩ・cm or less)

3: (1) Facility water temperature: 32 oC, (2) Circulating fluid: Clean water, (3) Circulating fluid temperature: 20 oC, (4) Circulating fluid flow rate: Rated flow rate, (5) Power

supply: 200 VAC

4: (1) Facility water temperature: 32 oC, (2) Circulating fluid: Clean water, (3) Circulating fluid flow rate: Rated flow rate, (4) Power supply: 200 VAC

5: (1) Facility water temperature: 32 oC, (2) Circulating fluid: Clean water, (3) Circulating fluid temperature: 20 oC, (4) Load: Refer to the specified cooling capacity (5)

Circulating fluid flow rate: Rated flow rate, (6) Power supply: 200 VAC, (7) Piping length: Minimum

6: With pressure control function using an inverter. When the pressure control function is not being used, the pump power supply frequency setting function can be used.

7: Required flow rate to maintain the cooling capacity. When the flow rate is lower than the rated flow, use a by-pass piping set.

8: To be prepared by the user. A specified earth leakage breaker is installed for option B, B1 and S “ With earth leakage breaker”.

9: The anchor brackets (including M8 bolt x 6pcs.) are used for fixation with the skid when this product is packed. The anchor bolts are not attached.

Loading...

Loading...