Edition

2022

Workshop Manual

PARK 300 M - PARK 300

Chapter

5 Belts

Page

32

5.1 Theory on the use of belts

5.1.1 Why is it so important to use genuine belts supplied by authorized vendors?

The table below shows the specications for commercially available belts compared to the

requisites of genuine belts supplied by an authorized vendor. The latter are designed and

made with close collaboration between the belt supplier and the machine manufacturer.

The table is to help you understand the importance of using genuine belts.

Example

Commercially

available belts

Genuine spare

belts

Notes

Fitting on the pulley.

The belt rests its

sloping sides against

the walls of the

pulley. There must

be a gap between

the belt and the

bottom of the

groove.

The belt rests its

sloping sides against

the walls of the

pulley. There must

be a gap between

the belt and the

bottom of the

groove.

Same requirements.

Genuine spare belts

ensure a perfect t

on the pulley.

Acceleration.

Some belts slot into

the pulleys only

when the engine is

running at operating

speed and this

generates excessive

heat.

The belt follows

the engine speed

in continuous

acceleration until the

maximum speed is

reached.

Ordinary belts are

made from natural

rubber which can

only withstand

temperatures of up

to 70°C.

Genuine spare

belts are made from

chloroprene rubber

which can withstand

temperatures of up

to 90°C.

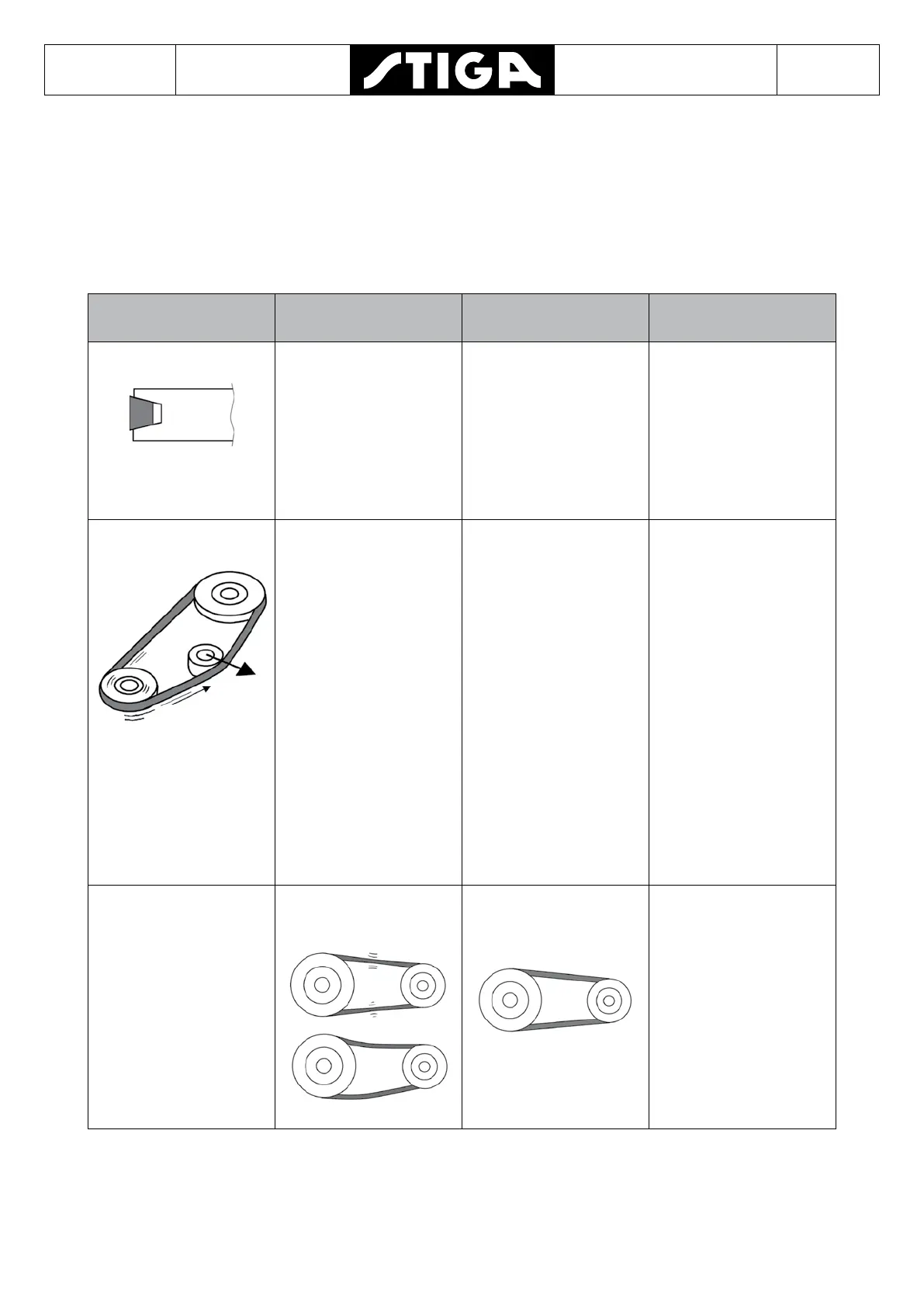

Length Made with standard

length pitch.

Made to a specied

length designed to t

the pulley perfectly.

The distance

between pulleys is

xed. The tensioner

ensures that the

genuine belt has the

optimum tension.

Loading...

Loading...