STIHL 009, 010, 011 41

7.

an

an

ent 7.

otes on

epa

Chain oil supply system

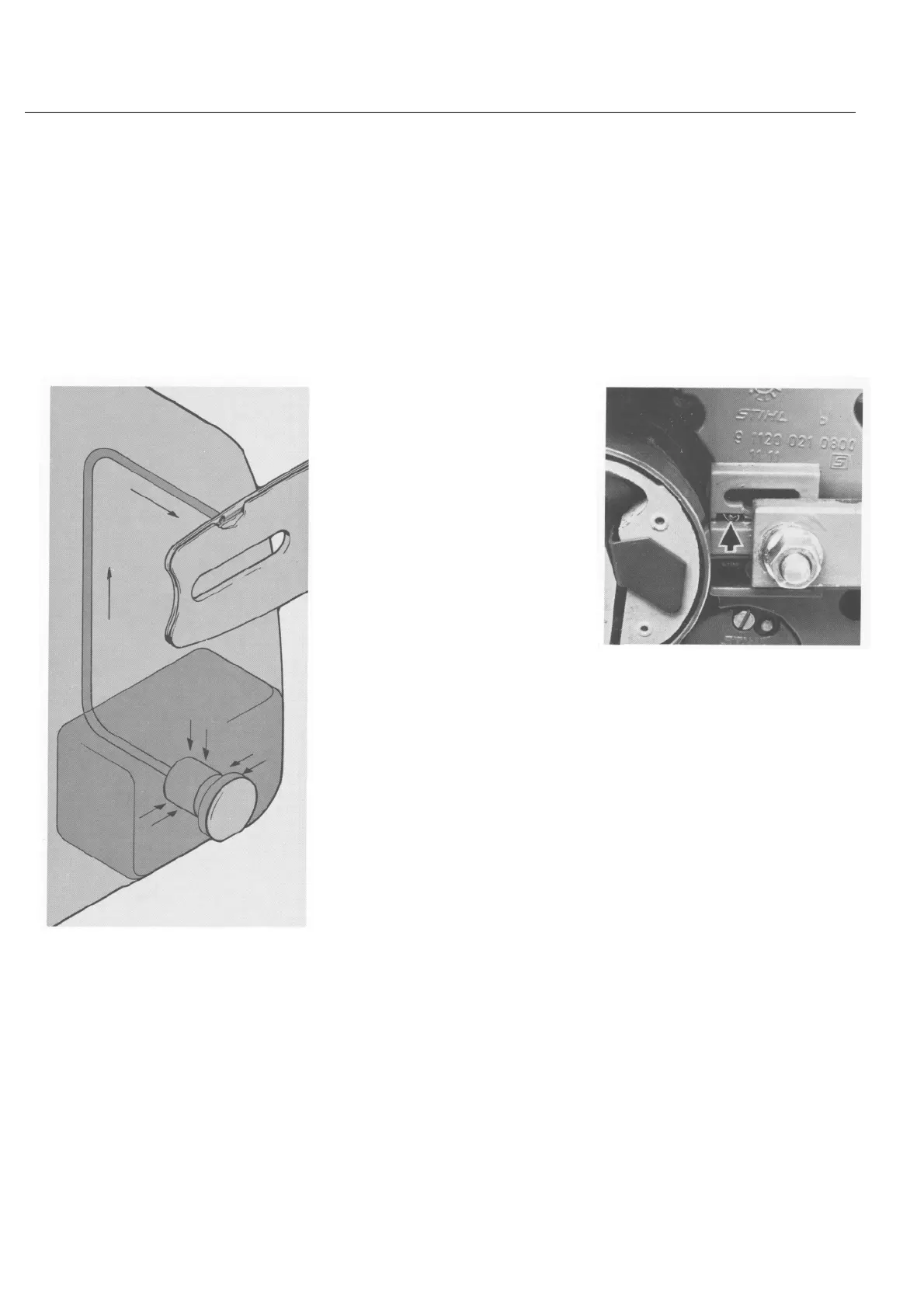

Split pin in vent hole

sure in the oil tank. This is necessary

because the pump would not

otherwise operate, i. e. the airtight

seal provided by the oil filler cap

would cause a vacuum to be created

in the oil tank as the oil level drops

and thus negate the suction of the oil

pump.

There is a vent hole in the crankcase

below the chain oil outlet to insure

that equal pressures are maintained

inside and outside the oil tank. A split

pin is fitted in the vent hole which

allows air to enter but also prevents

the ingress of dirt and the loss of

chain oil from the tank.

If the vent hole is caked with dirt, it

can blown be out with compressed

air. Stubborn particles of dirt can be

loosened by turning the split pin

carefully to and fro and then blown

out with compressed air.

If the two halves of the crankcase are

separated during a repair, the pulse

hole in the sprocket side of the

crankcase should be examined for

deposits of foreign matter. If any are

found, they should be cleaned away

with the pump housing removed.

If the machine has not been in use for

an extended period, the pump plunger

may be stuck in the pump housing

owing to resin in the oil. In such a

case the pump must be disassembled

and washed in clean gasoline.

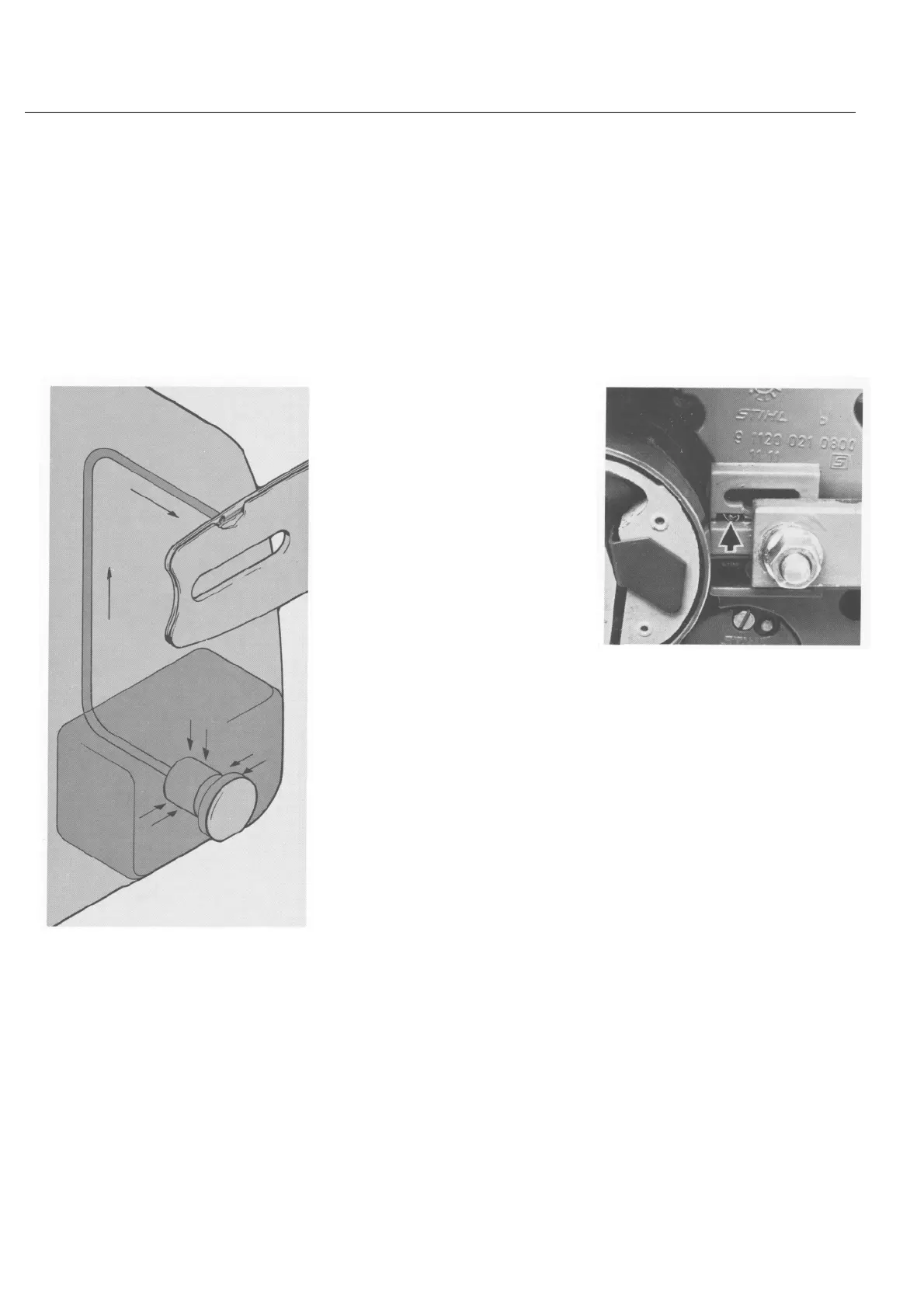

The chain oil tank is an integral part of

the crankcase. The oil pump - which

is operated by the alternating

pressures in the crankcase - draws

chain oil through a filter and into the

pump housing. It then feeds it through

a rubber hose to the oil inlet hole in

the guide bar.

A precondition for correct operation of

the oil pump is that the pressure in

the pump housing during the intake

stroke must be lower than the pres

Loading...

Loading...