STIHL 009, 010, 011 48

.5

epa

r o

ar

ureto

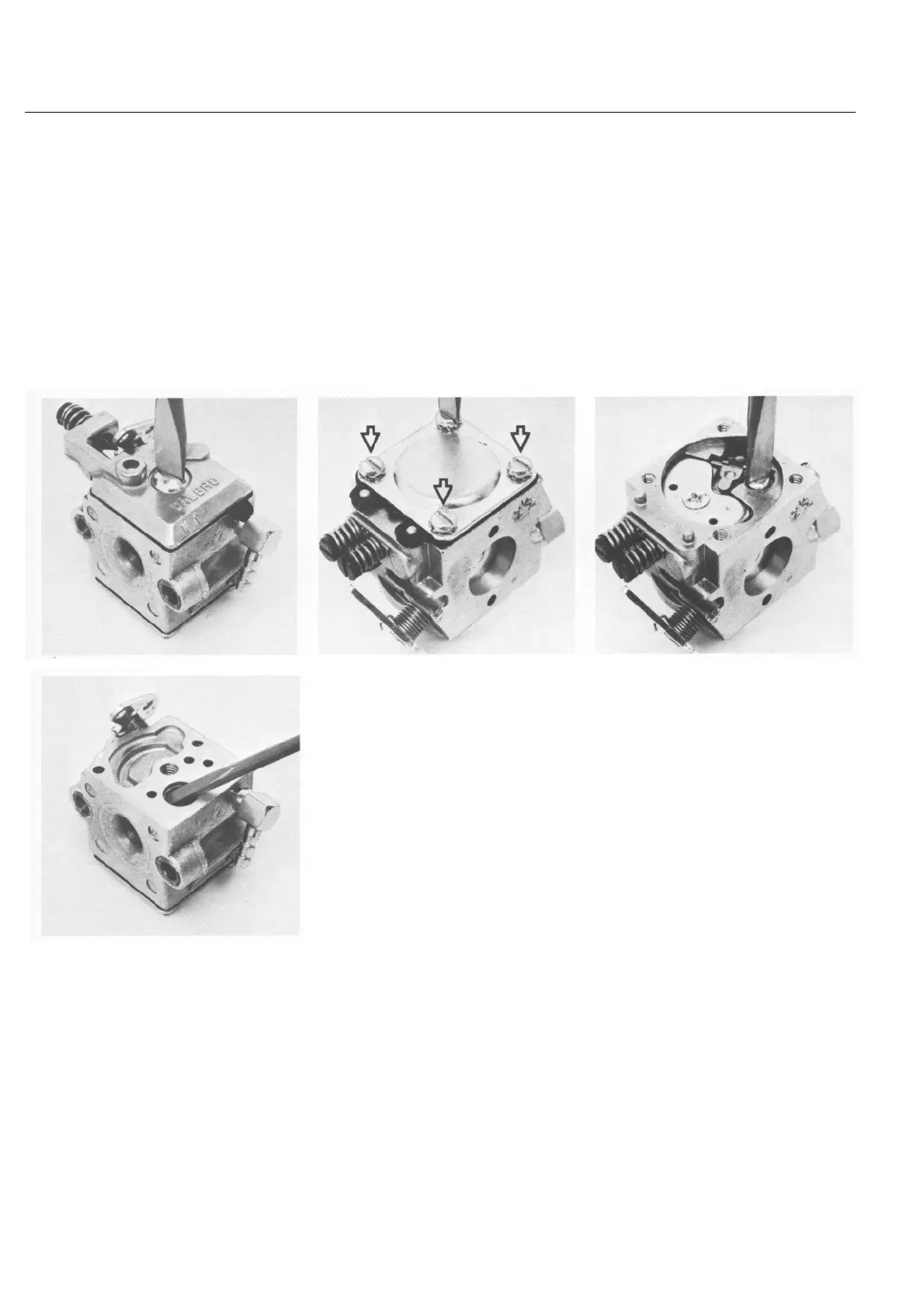

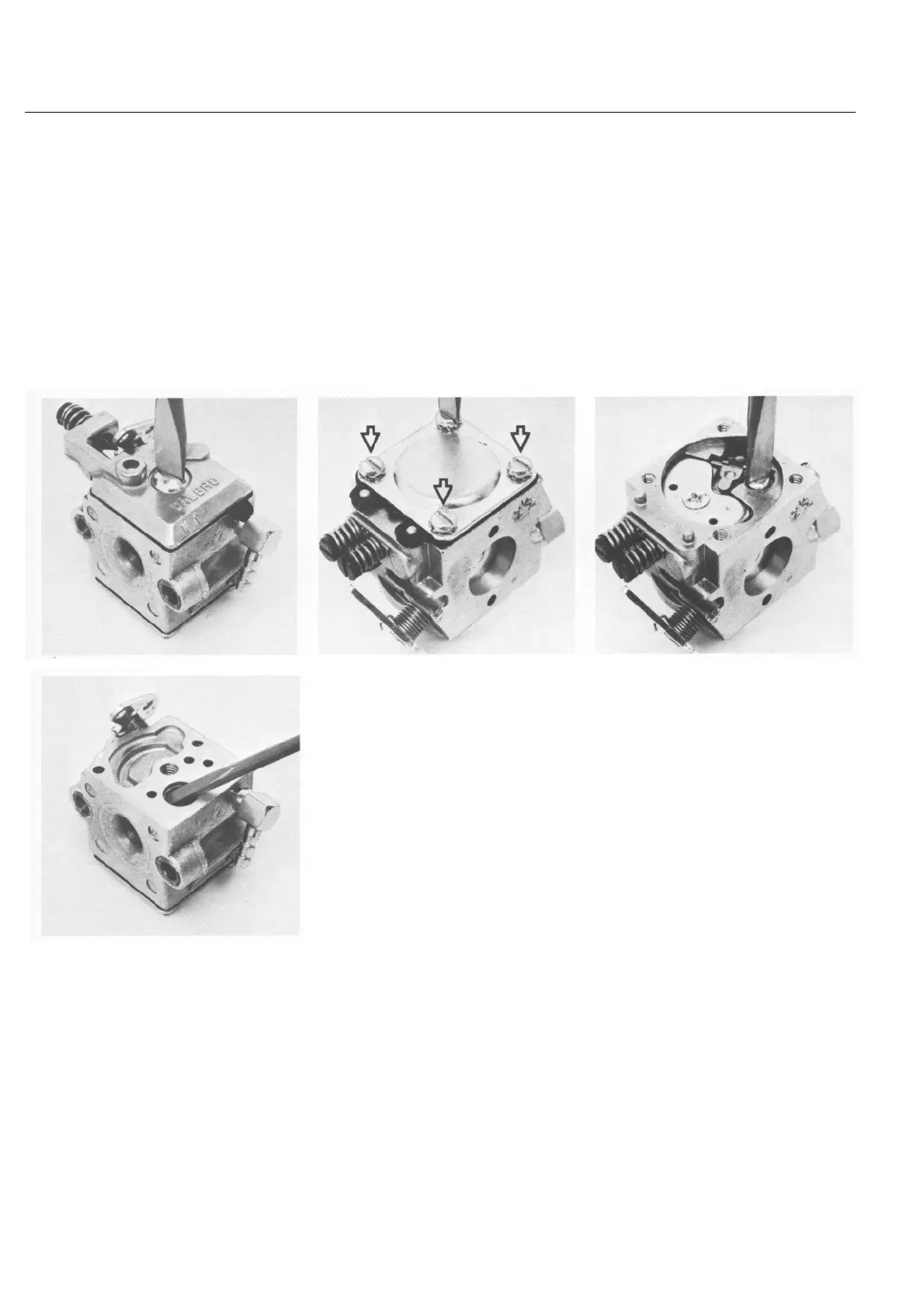

It is advisable to check the service-

ability of the fuel pump whenever the

carburetor is removed for repair.

Unscrew the fuel pump end cover and

remove the gasket and pump

diaphragm. The end cover, gasket

and diaphragm are frequently stuck

together. If this is the case, take parti-

cular care when separating them. If

the fuel strainer in the pump side of

the carburetor body is dirty, it should

be lifted out with a screwdriver and

washed in clean gasoline. Always

replace the fuel strainer if it shows

any signs of damage.

To disassemble the carburetor body,

unscrew the metering chamber cover

and remove the metering diaphragm

and gasket. This diaphragm and gas-

ket may also be stuck together and

must be separated carefully.

The diaphragms are the most

delicate parts of the carburetor. Due

to the continuous alternating stress

to which the diaphragms are

subjected, the material eventually

shows signs of fatigue - the

diaphragms distort and swell. When

this stage is reached the carburetor

can no longer function correctly and

the diaphragms must be replaced.

The inlet needle valve is located in a

recess in the metering diaphragm

chamber. The inlet control lever with

spindle, helical spring and inlet

needle can be removed after

unscrewing the round head screw. If

an annular indentation is visible on

the cone of the inlet needle, it should

be replaced as it will no longer seal

properly. This is indicated by

constant flooding of the carburetor

although the needle is clean.

Top:

Removing fuel pump end cover

Bottom:

Taking out the fuel strainer Removing metering chamber cover Removing inlet needle

Loading...

Loading...