Oilsealstendtofailwhen

subjectedtoavacuum,i.e.the

sealinglipliftsawayfromthe

crankshaftduringthepiston’s

inductionstrokebecausethere

isnointernalcounterpressure.

Anadditionaltestcanbecarried

outwiththevacuumpumpto

detectthiskindoffault.

-Carryoutpreparations-

see5.3.1.

•

Connectthesuctionhoseof

vacuumpump00008503501

totestflangenipple.

•

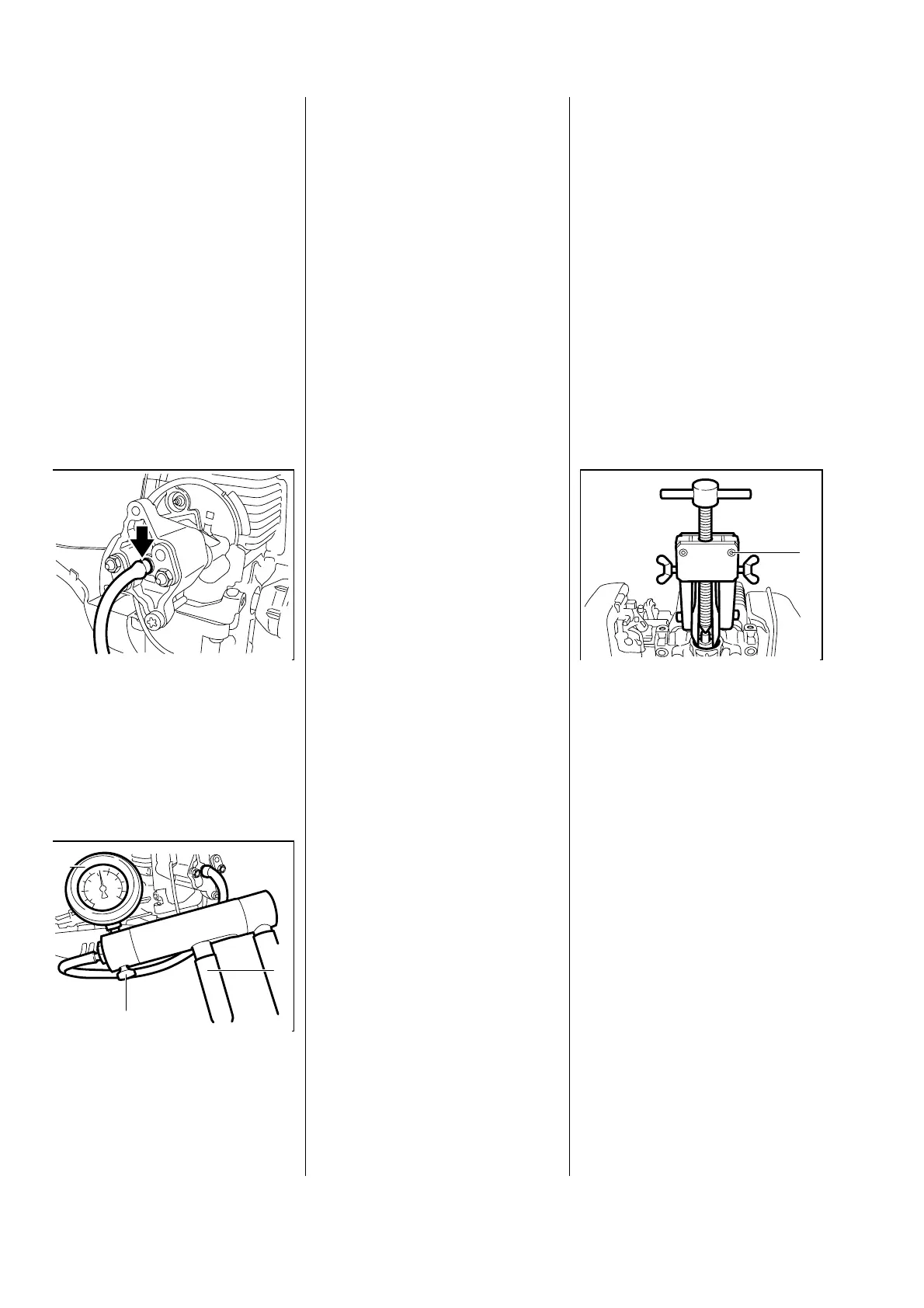

Closeventscrew(1)on

pumpcylinder.

•

Operatelever(2)untilthe

gauge(3)indicatesavacuumof

0.5bar(7.25psi).

Note:Ifthevacuumreading

remainsconstant,orrisestono

morethan0.3bar(4.25psi)within

20seconds,itcanbeassumed

thattheoilsealsareingood

condition.

However,ifthepressurecontinues

torise(reducedvacuuminthe

crankcase),theoilsealsmustbe

replaced.

-Afterfinishingthetest,openthe

ventscrewanddisconnectthe

hose.

-Removethetestflange.

-Slackenoffthemufflerscrews.

-Removethesealingplateand

tightenscrewsto9.0Nm

(6.6lbf.ft)festziehen.

-Installthecarburetor-see9.2.2.

-Fittheshroud.

Itisnotnecessarytodisassemble

thecompleteenginetoreplacethe

oilseals.

Starterside:

-Removethestartercup-see7.4.

-Removetheenginehousing-

see4.1.

•

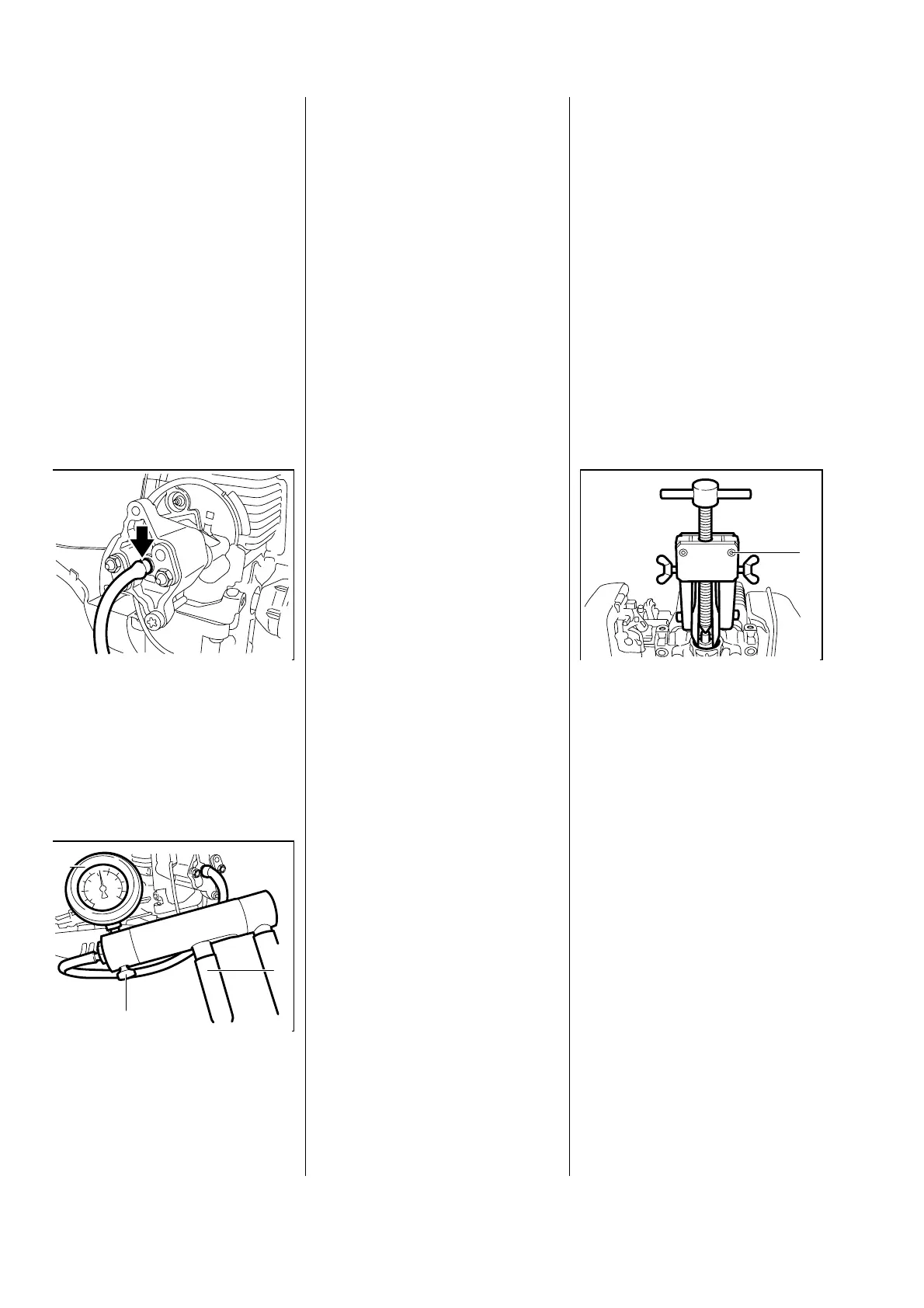

Applythepuller(1)

59108904400(withNo.3.1

jaws00008933706).

-Tensionthearms.

-Pullouttheoilseal.

Important:Takecarenotto

damagecrankshaftstub.

-Cleansealingsurfacewitha

standardsolvent-baseddegrea-

santcontainingnochlorinatedor

halogenatedhydrocarbons-

see11.2.

-Lubricatesealinglipsofoilseal

withgrease-see11.2.

5.3.3 VacuumTest 5.4 OilRings

VA

232RA038

1

VA

232RA037

1

2

3

VA

232RA035

12 FS45

Loading...

Loading...