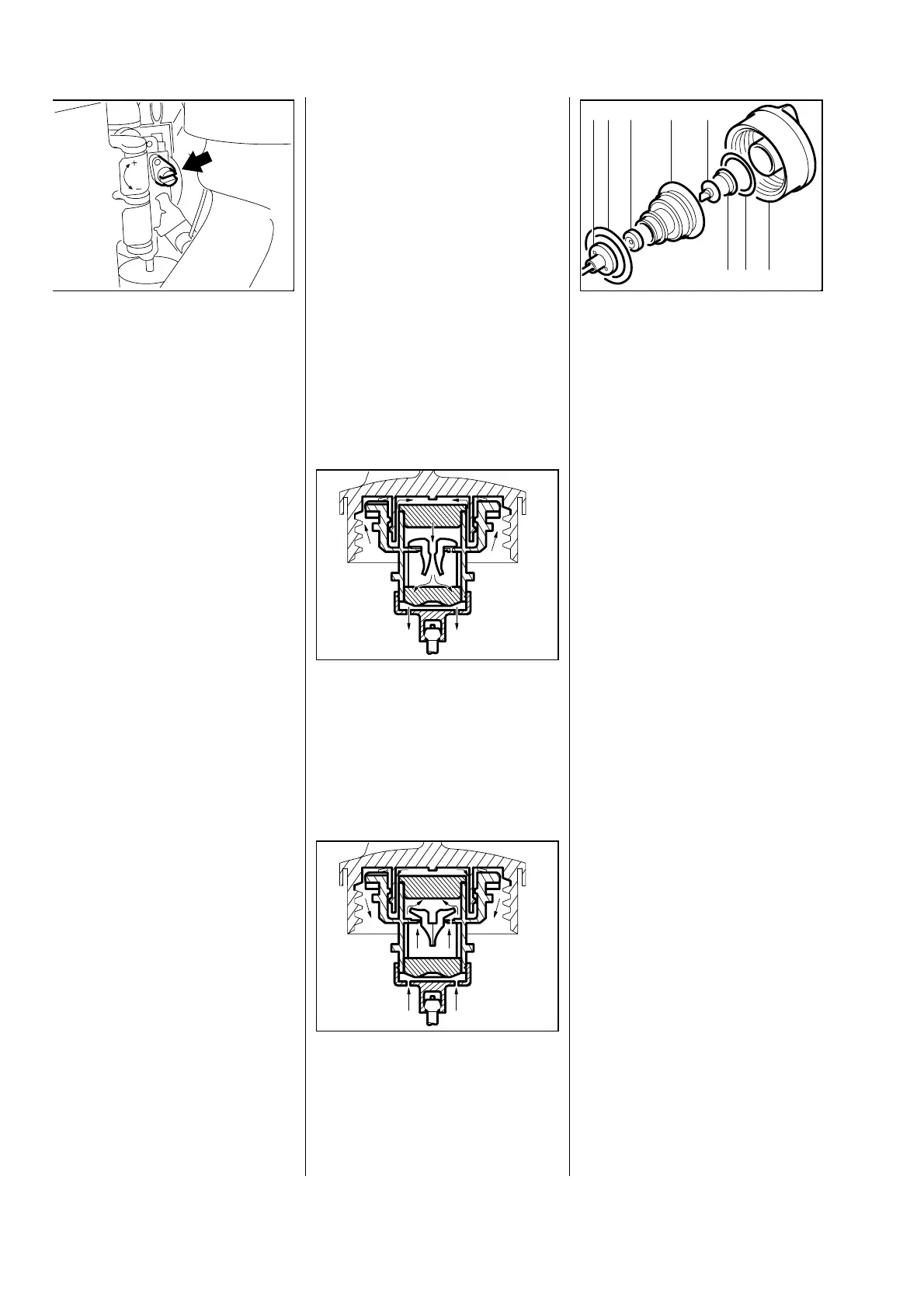

Adjusting idle speed

Engine stops while idling:

•

Turn the idle speed screw (LD)

clockwise until engine runs

smoothly – cutting tool must not

rotate.

Cutting tool rotates while

engine is idling:

•

Turn the idle speed screw (LD)

counterclockwise until cutting

tool stops rotating – and then

turn screw about another one

full in the same direction.

Correct operation of the carburetor

is only possible if atmospheric

pressure and internal fuel tank

pressure are equal at all times.

This is ensured by the tank vent.

Important: If problems occur on

the carburetor or the fuel supply

system, always check and clean

the tank vent.

Check function by performing

pressure and vacuum tests on

the tank via the fuel hose.

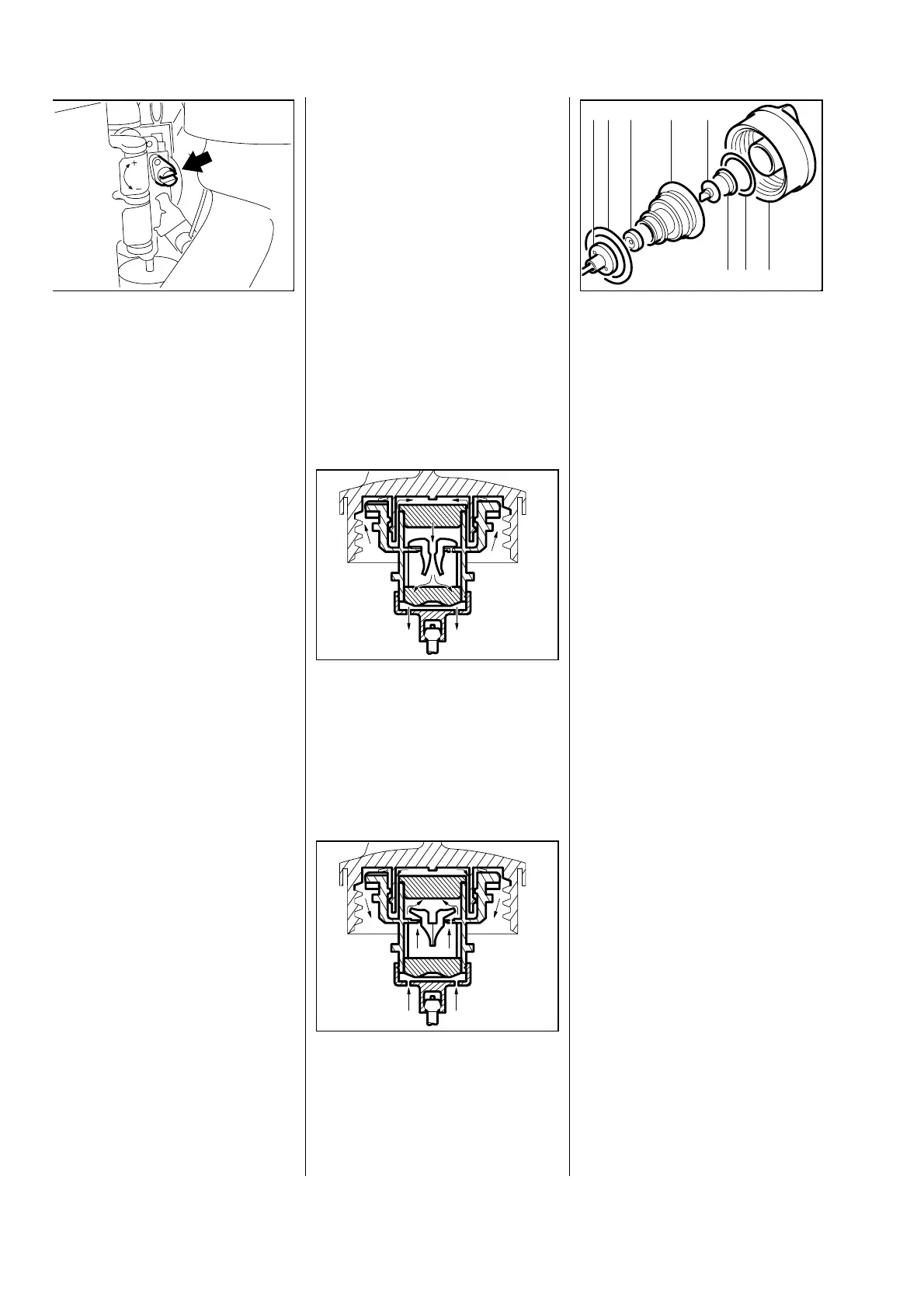

Equalizing pressure

Equalization of pressure from the

outside inwards takes place via

the thread in the fuel filler cap,

the slots in the valve body, the

sintered filter and the holes in

the cap.

Equalization of pressure from the

inside outwards takes place via

the holes in the cap, the sintered

filter, the slots in the valve body

and the thread in the fuel filler cap.

Cleaning

- Unscrew the fuel filler cap.

•

Ease the cap (1) off the valve

body (2).

•

Take sintered filter (3) out of cap.

•

Pry valve body out of fuel filler

cap (4).

•

Take the cup spring (5) out of

the filler cap.

•

Pry sintered filter (6) out of fuel

filler cap.

- Wash valve body in clean

gasoline.

•

Remove the valve (7) and fit a

new one.

•

Push new sintered filter (6) into

filler cap.

•

Fit sealing ring (8) over valve

body.

•

Fit cup spring (5) in the filler cap.

- Fit valve body in filler cap and

press it home until it snaps into

position.

- Fit new sintered filter in the cap.

- Fit cap on valve body and press

it down until it snaps into position.

- Refit the fuel filler cap.

9.3 Tank Vent

VA

232RA090

LD

VA

232RA091

VA

232RA092

VA

232RA093

1 8

3 2

7

6 5 4

30 FS 45

Loading...

Loading...