0458-729-8621-A

42

English

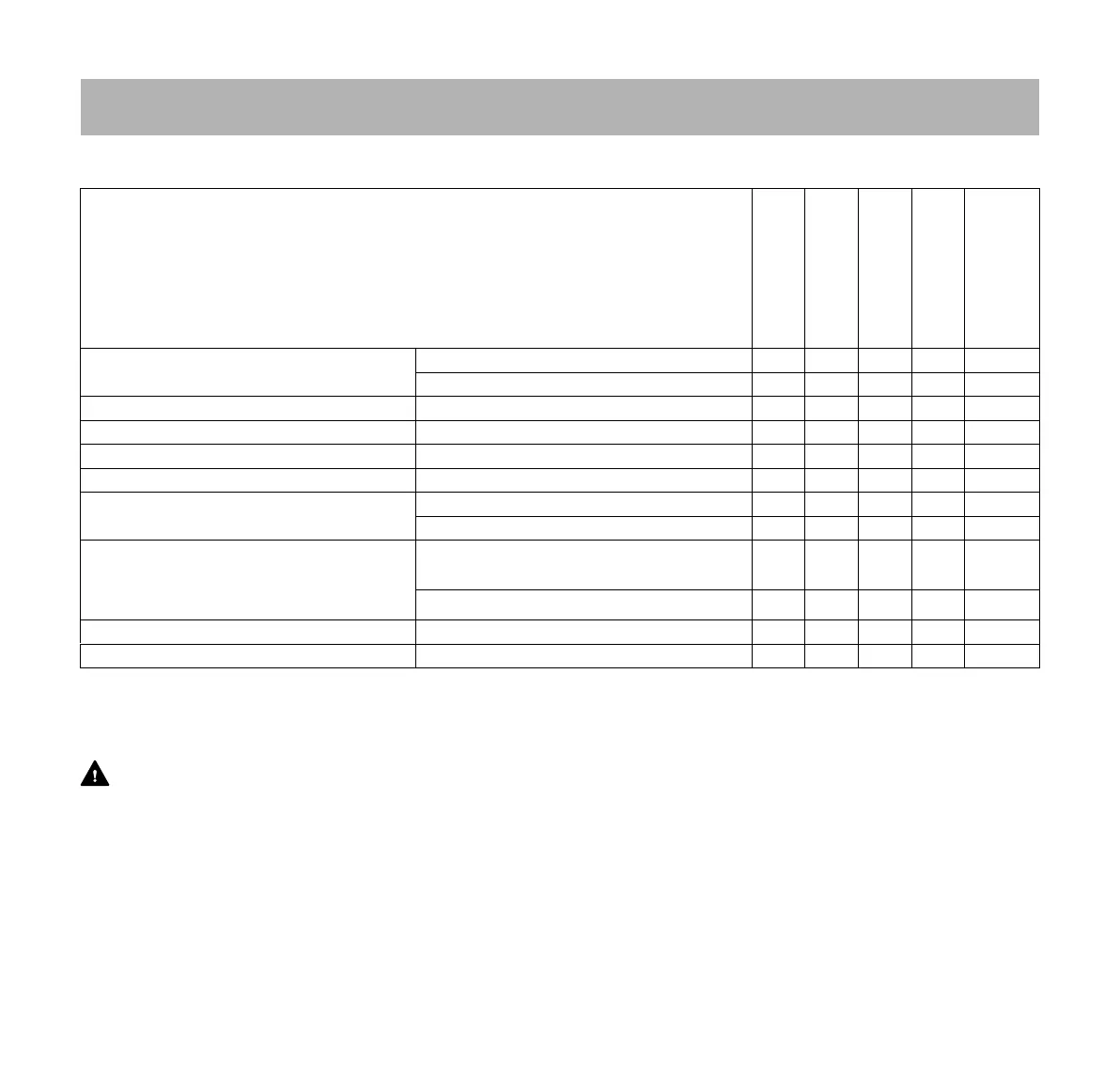

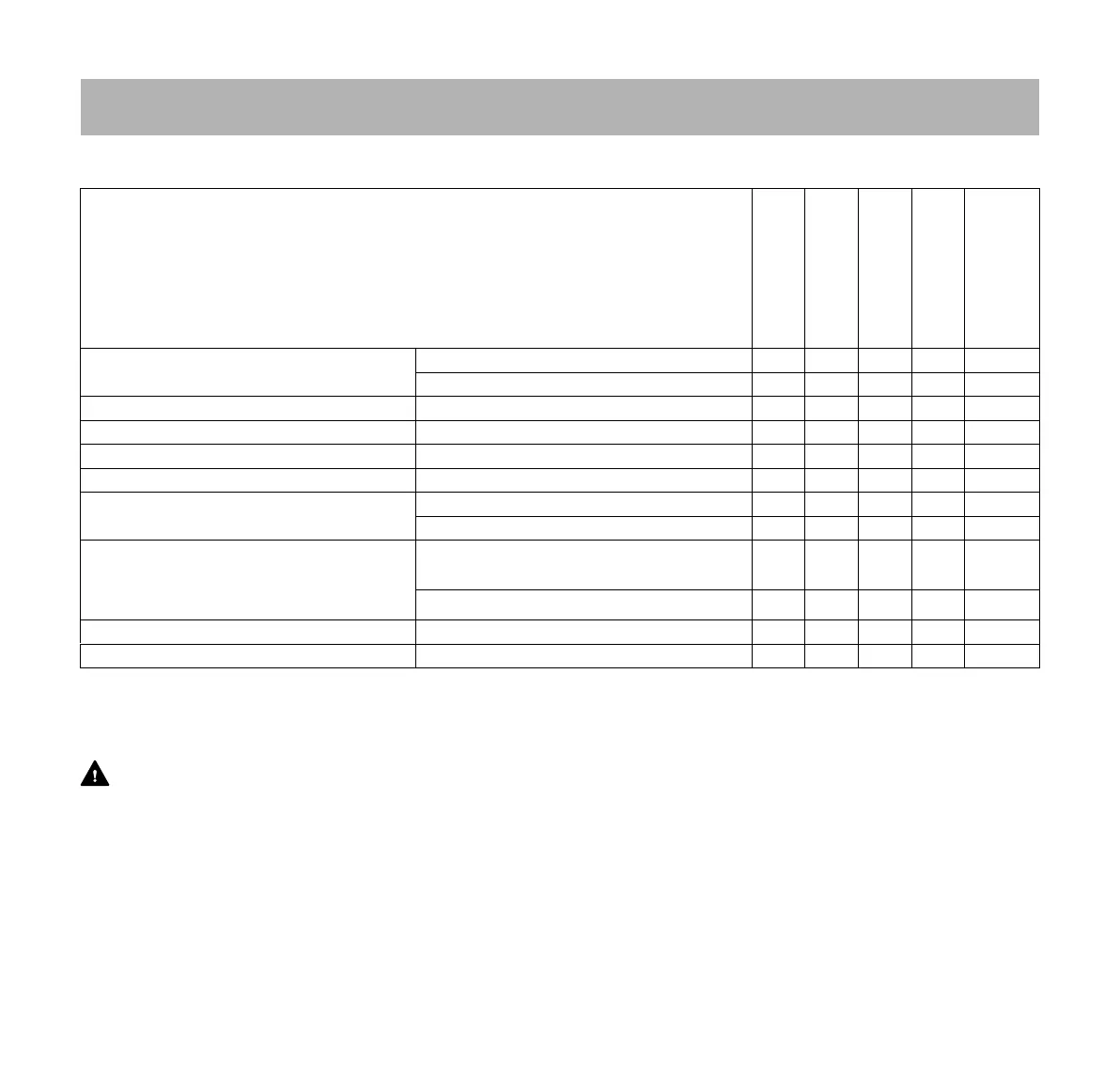

20 Inspection and Maintenance

20.1 Inspection and Maintenance Chart

20.2 Inspecting and Maintaining the Chain Saw

WARNING

To reduce the risk of personal injury from unintended

activation, disconnect the chain saw from the power supply

and engage the chain brake before inspecting the chain saw

or carrying out any maintenance, @ 9. Carry out only the

maintenance operations described in this manual. There are

no user-authorized repairs. STIHL recommends that repair

work be performed by authorized STIHL servicing dealers.

Proper maintenance of the chain saw includes the following

activities:

► Inspecting the chain sprocket periodically and having a

worn chain sprocket replaced by an authorized STIHL

servicing dealer.

► Inspecting the guide bar for proper groove depth and

spread and replacing the guide bar if it shows signs of

excessive wear or damage.

20 Inspection and Maintenance

The following maintenance intervals are examples and apply for normal operating

conditions. Actual use and your experience will determine the frequency of required

inspection and maintenance.

Before starting

work

After finishing work

or daily

Weekly

Monthly

Relevant Chapter

Complete Machine Visual inspection X

Clean X @ 19.1

Controls Check function and condition X @ 15.2

Chain Brake Check function

1)

X @ 15.1

Chain Oil Tank Clean

1)

X

Chain Lubrication Check chain oil flow rate X @ 15.3

Saw Chain Check chain tension X @ 11.3

Sharpen

1)

XX@ 20.5

Guide Bar Inspect for proper groove depth and

spread

X

@ 20.4

Deburr X @ 20.4

Chain Sprocket Inspect X @ 20.3

Chain catcher on sprocket cover Inspect X

1)

STIHL recommends a STIHL servicing dealer.

Loading...

Loading...