TROUBLESHOOTING

11

59

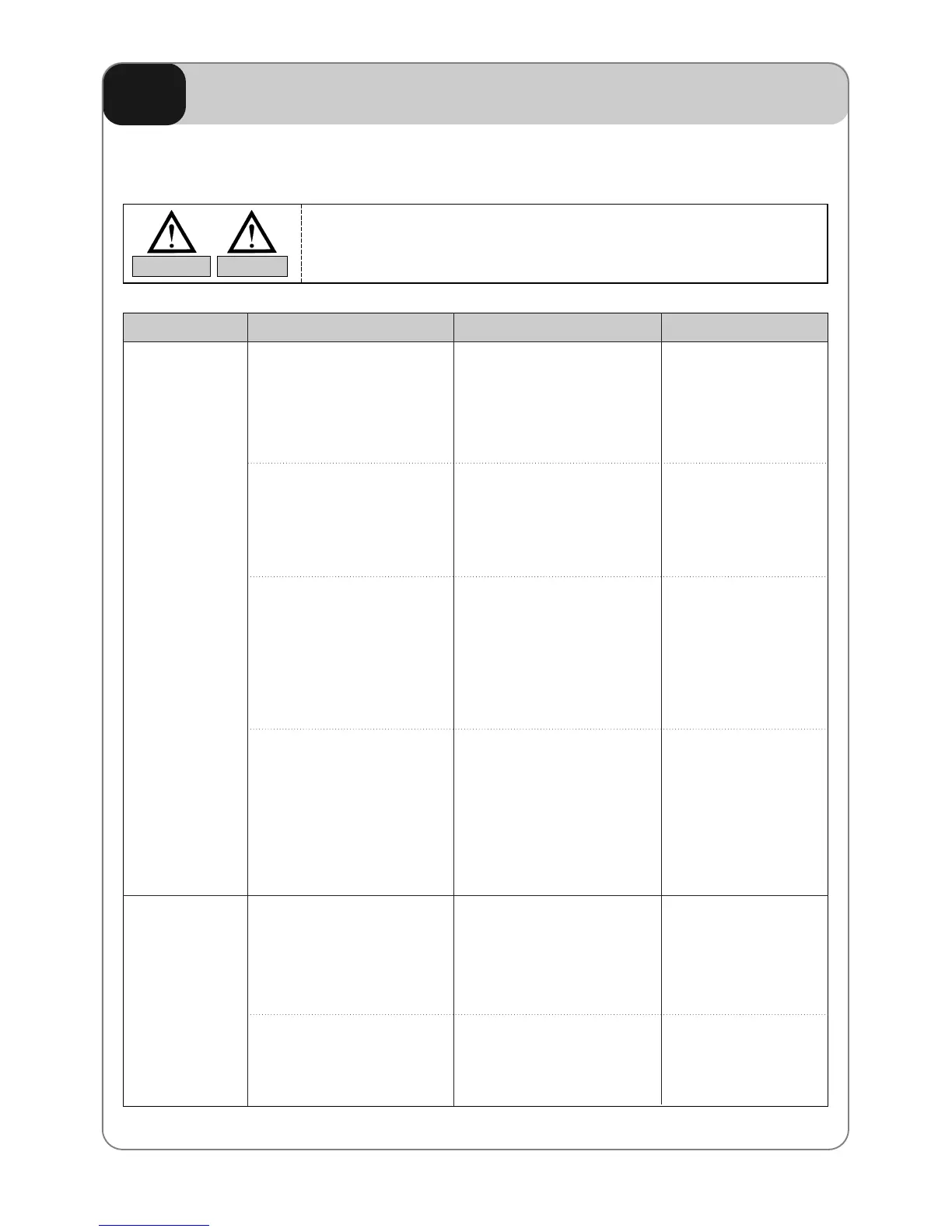

11.1) CAUSES AND TROUBLESHOOTING

Inspect/repair the machine by the guideline in machine failures.

CAUTION DANGER

Operation failure

Incorrect Stop

Position

① Loose belt tension or belt

damage

② Power failure or short-circuit

of fuse

③ Failure to detect signals for

needle position or for 1

rotation

④ Frame out of X or Y limit

① Loose tension on main

driver belt

② Incorrect position of encoder

or bad encoder

■ Adjust belt tension/ change

belt

■ Change fuse in the power

socket

■ Manually move color

change. Check if the signal

blinks at the correct needle

position in the operation box

■ Adjust design start point

(Move the frame manually

so the design comes into

the scope)

■ Change belt

■ Adjust position or change

encoder

Check

① main driver belt

② X-Y timing belt

Inspection & Repair CauseError Type Reference

Loading...

Loading...