OM3750 Rev. 5 11 January 2004

Page 6 of 24

Avoiding Vibration

All centrifuges have critical speeds at which vibration

occurs. As the speed increases beyond the critical speed,

vibration will cease. This inherent condition also occurs

during deceleration. An imbalanced load intensifies these

critical vibrations. You should avoid running the centrifuge

at or near its “critical speed” to avoid excessive vibration.

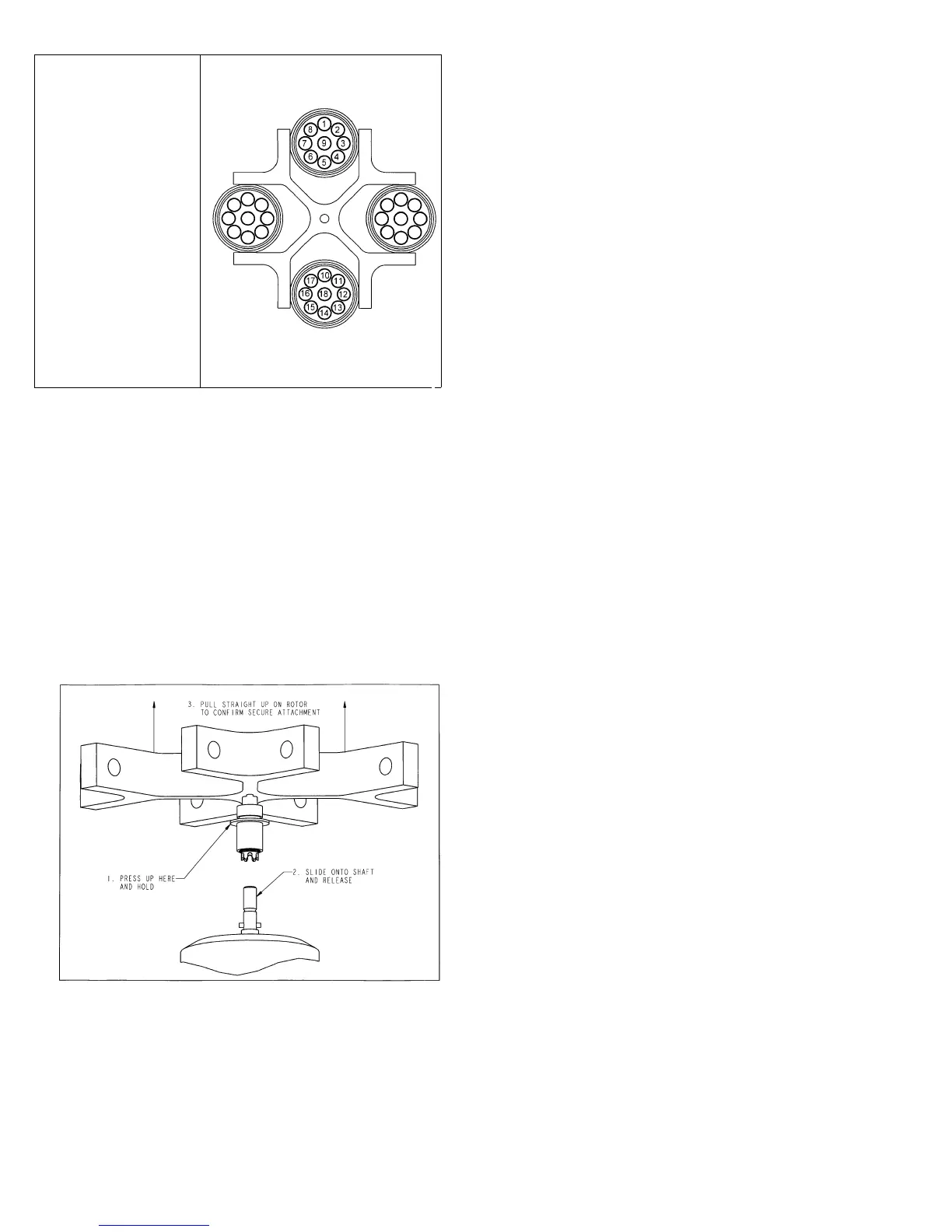

Rotor Installation

To install the rotor:

1. Press the disk (located on the underside of the rotor) to

the rotor.

2. Slide the rotor over the shaft, until it snaps into place.

Release the disk.

3. Pull the rotor straight up, to insure a positive lock.

Rotor Removal

To remove the 243 rotor:

1. Press the disk (located on the underside of the rotor) to

the rotor.

2. Lift the rotor straight up.

3. Release the disk.

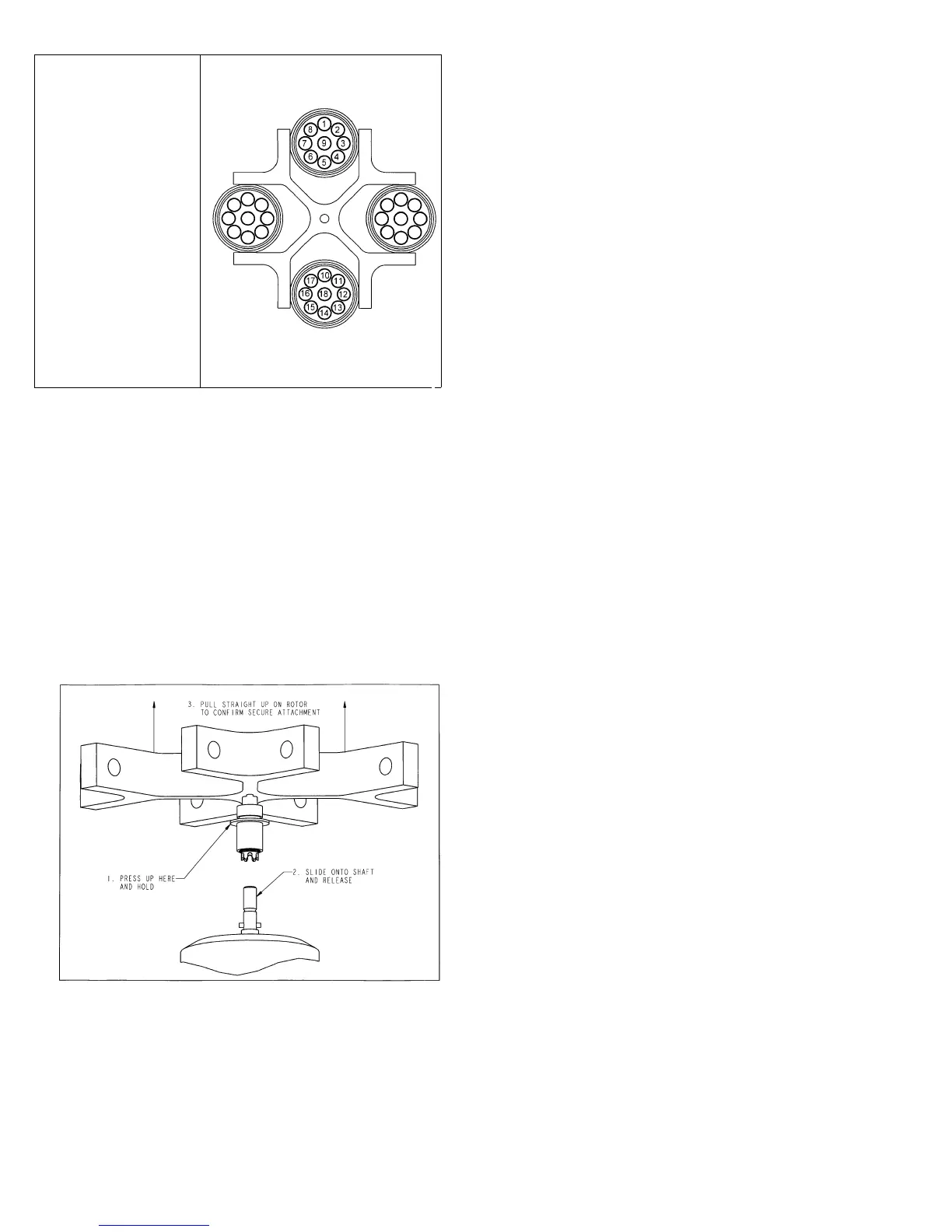

1. Load two tubes at

positions: 9 and

18.

2. Load four tubes at

positions:

1, 5 and 10, 14

or

7, 3 and 16, 12

3. Load six tubes at

positions:

1, 9, 5 and 14, 18,

10

or

7, 9, 3 and 12, 18,

16

4. Loading an odd

number of tubes is

not recommended.

Rotor Adapter

To install the shaft adapter for an existing rotor:

1. Press the adapter disk and slide the adapter over the

rotor shaft. Release the disk.

2. Pull the adapter straight up to insure a positive lock.

3. Align the rotor keyway with the key on the shaft

adapter and place the rotor onto the adapter.

4. Tighten the rotor locking nut (with the provided

wrench), until it tightly engages the rotor.

To remove existing rotors from the shaft adapter:

1. Remove any sample tubes, shields, buckets, and other

accessories, from the rotor.

2. Unscrew and remove the locking screw.

3. Grasp the rotor and rock it front-to-back, and side-to-

side.

4. Remove the rotor from the shaft.

3.2 Starting and Stopping a Run

The display above the Program key shows the unit’s

operating mode:

• blank The unit is in manual operation.

• 1-99 The unit is under control of the displayed

stored program number.

• C The unit is set to Rapid Condition, a special

program discussed in Section 3.4.

The rest of the display indicates the last parameters

selected.

Manual Operation

For manual operation:

1. Press the MANUAL key so that the program display is

blank.

2. Select the desired temperature (refrigerated system

only).

3. Select the speed/g-force, run time, acceleration mode,

and braking mode.

4 . P r e s s S T A R T t o s t a r t t h e s p i n .

The time display counts down, and displays the time

remaining in the current spin, during manual operation.

The specified run time begins when the START key is

pressed. Braking begins when the set time elapses. Run

time does not include braking time.

The spin will stop automatically at the end of the desired

interval.

IMPORTANT:

A run can be stopped at any time by pressing the STOP

key.

The settings can be changed during a manual run. These

changes affect the run in progress. If the time setting is

changed during a run the unit adjusts the count-down timer

to display the revised setting as the total time of the run. If

the new time selected is less than the elapsed time, the run

will end.

The unit’s mode (settings) cannot be changed during a

program mode spin.

Loading...

Loading...