36

7

ENGINE OPERATION

ENOM00042-0

ENOM00246-0

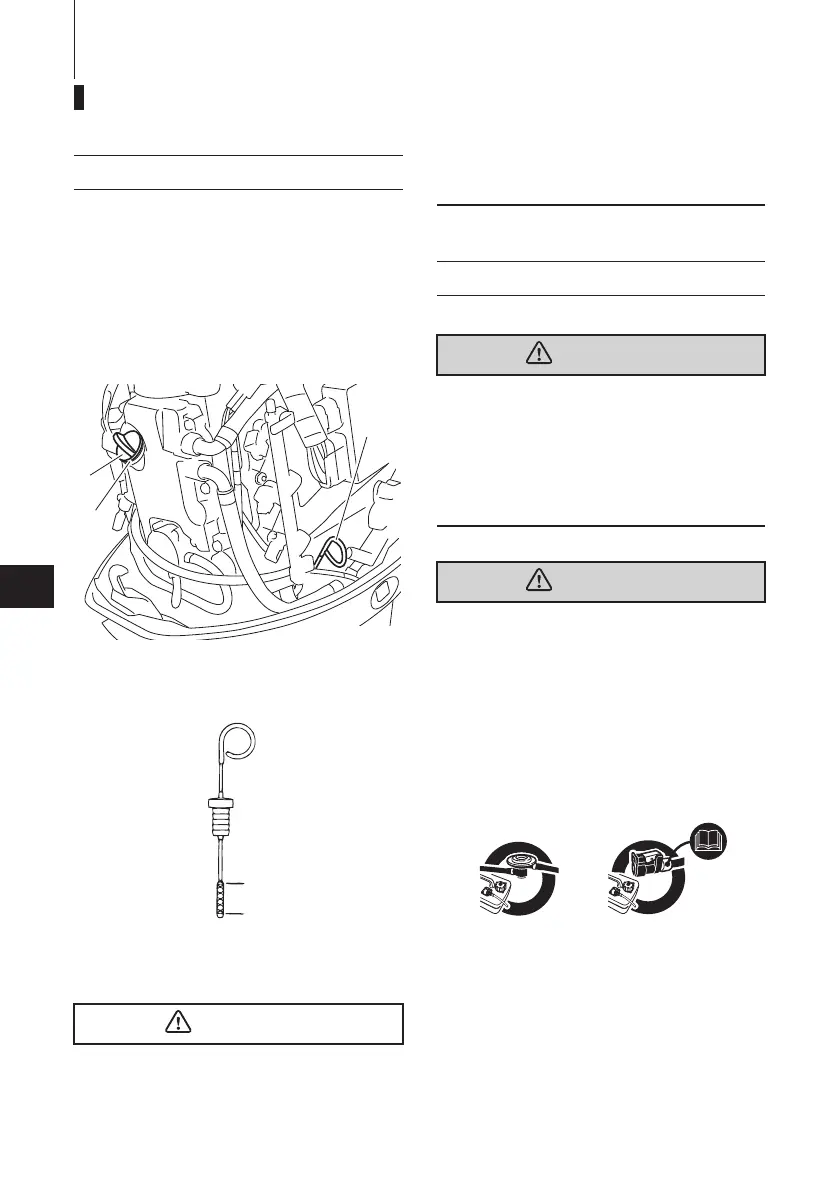

Oil Level checking

Check the engine oil level before each

use. If the oil level is low or too high, the

life of the engine will be shortened signif-

icantly.(To properly check the engine oil

level follow the instructions,

see page 66)

1. Filler cap

2. Dipstick

3. Filler port

1. Upper limit

2. Lower limit

ENOW00027-B

Before starting engine for the first time after

reassembling engine or off-season storage,

disconnect stop switch lock and crank

approximately 10 times in order to prime the

oil pump.

ENOM00044-A

ENOW00029-A

When opening fuel tank cap, be sure to fol-

low the procedure described below. Fuel

could blast out through the fuel tank cap in

case the cap is loosened by using another

procedure when internal pressure of fuel

tank is raised by heat from sources such as

sun light.

ENOW00030-B

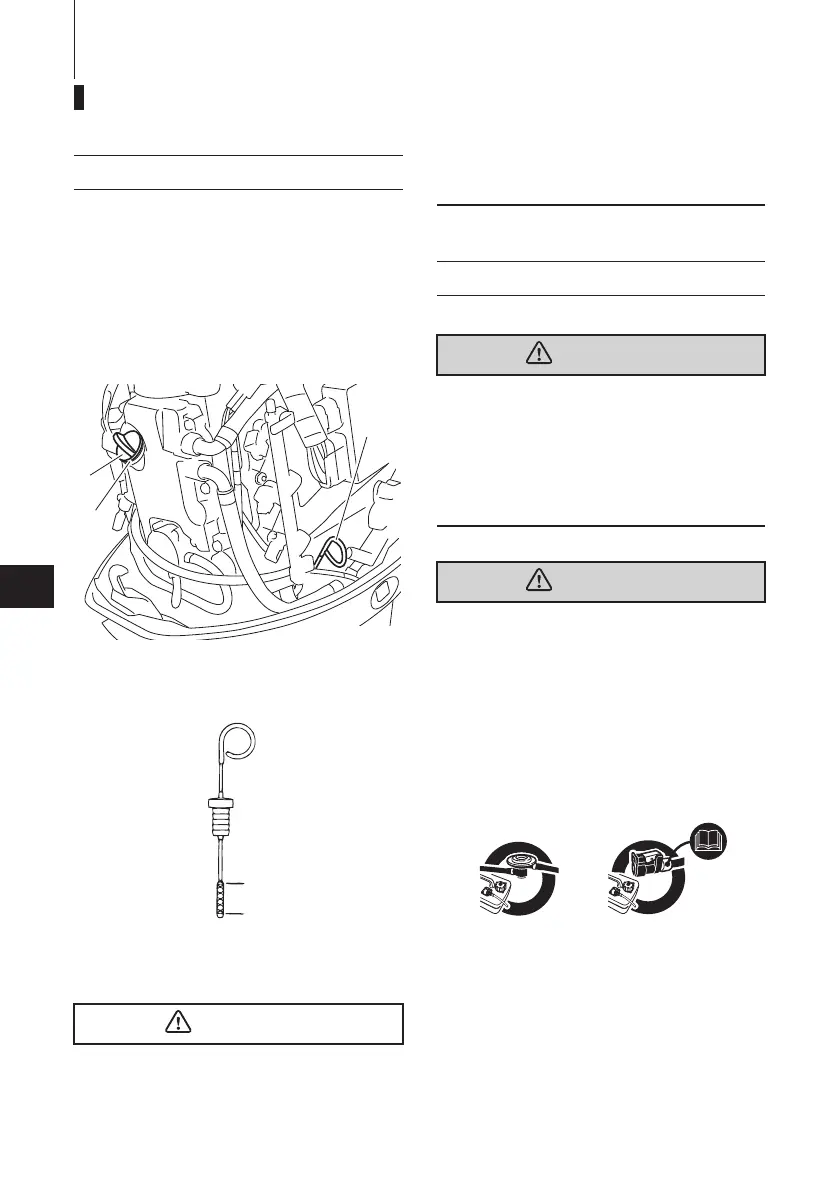

When using EPA approval fuel tank, only use

a primer bulb/hose assembly that has a Fuel

Demand Valve (FDV) installed in the fuel hose

or a sealing mechanism in the fuel connector

as shown below.

FDV and fuel connector that has an sealing

mechanism prevent pressurized fuel spill-

age when the fuel connector is connected to

the engine.

1. FDV in fuel hose

2. Sealing mechanism in fuel connector

3. Identification

Do NOT use a primer bulb/hose assembly

that does not contain a Fuel Demand Valve

or a sealing mechanism as shown below:

Before starting

CAUTION

2

1

ENOF00113-0

1. Fuel feeding

WARNING

WARNING

Loading...

Loading...