ServicingtheSparkPlug

ServiceInterval:Every100hours/Every6months

(whichevercomesrst)

Every300hours/Yearly(whichevercomesrst)

UseanNGKBPR6ESsparkplugorequivalent.

1.Shutofftheengineandwaitforallmoving

partstostop;refertoPreparingtheMachinefor

Maintenance(page25).

2.Cleanaroundthesparkplug.

3.Removethesparkplugfromthecylinderhead.

Important:Replaceacracked,fouled,or

dirtysparkplug.Donotsandblast,scrape,

orcleantheelectrodesbecauseengine

damagecouldresultfromgritenteringthe

cylinder.

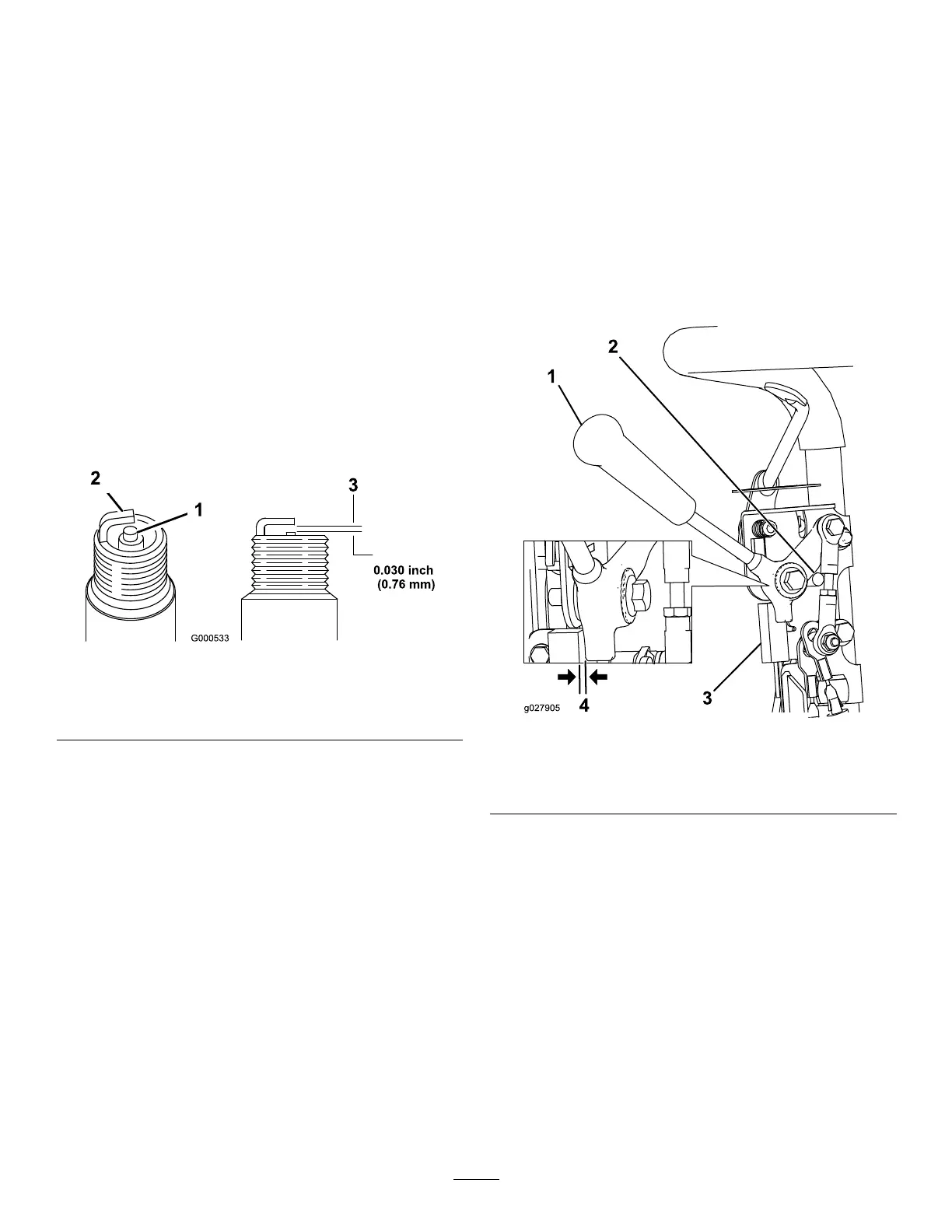

4.Setthegapontheplugto0.7to0.8mm(0.028

to0.031inch)

g000533

Figure30

1.Center-electrodeinsulator

3.Airgap

2.Sideelectrode

5.Carefullyinstallthesparkplugbyhand(toavoid

crossthreading)untilitishandtight.

6.Tightenthesparkpluganadditional1/2turnif

itisnew;otherwise,tightenitanadditional1/8

to1/4turn.

Important:Aloosesparkplugcanbecome

veryhotandcandamagetheengine;

overtighteningasparkplugmaydamagethe

threadsinthecylinderhead.

7.Connectthewiretothesparkplug.

ElectricalSystem

Maintenance

Servicingthe

Traction-InterlockSwitch

Usethefollowingprocedureifthetraction-interlock

switchneedsadjustmentorreplacement.

1.Ensurethattheengineisoffandthetraction

leverisdisengagedandrestingagainstthe

neutralstop(Figure31).

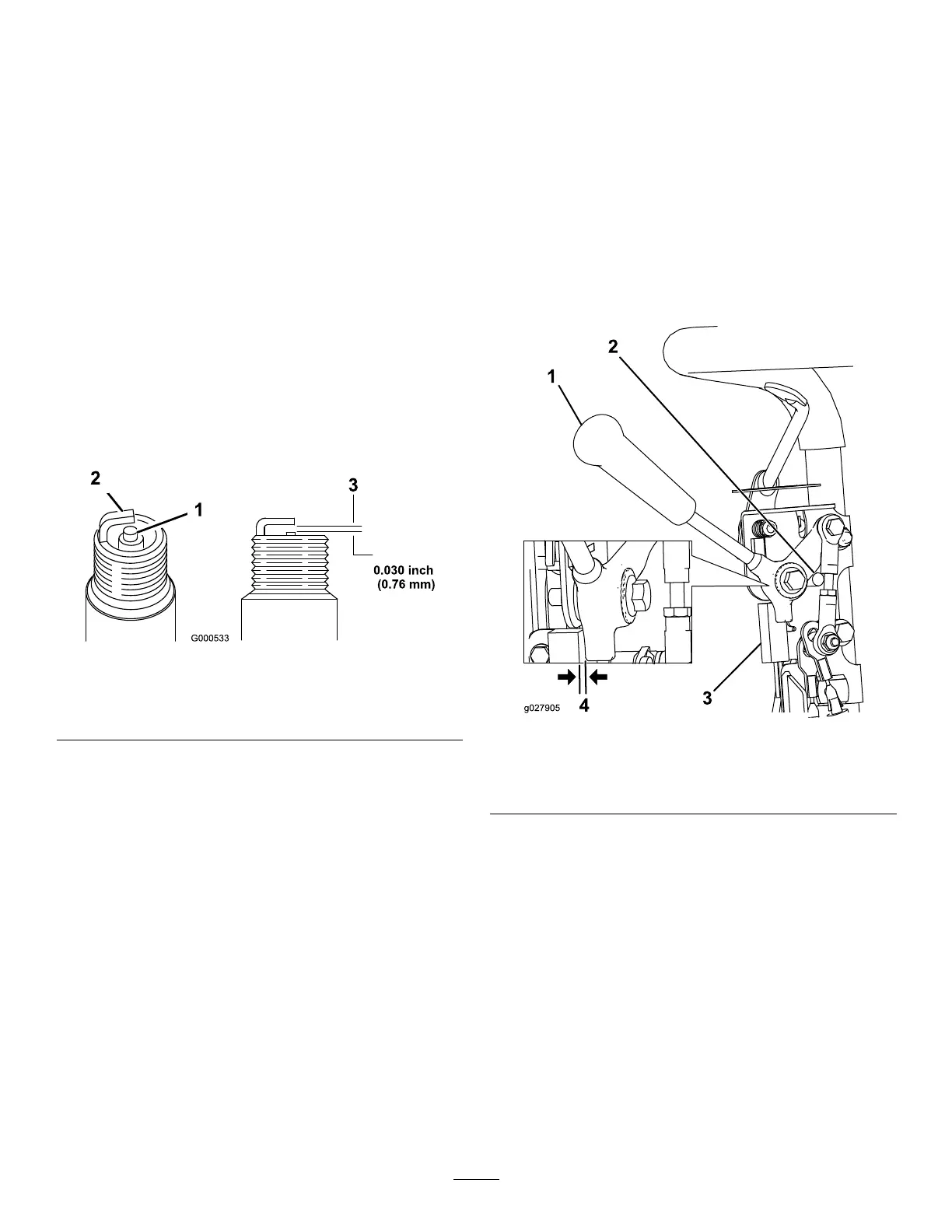

g027905

Figure31

1.Tractionlever3.Interlockswitch

2.Neutralstop

4.0.8mm(0.032inch)gap

2.Loosentheinterlockswitchmountingfasteners

(Figure31).

3.Placea0.8mm(0.032inch)thickshimbetween

thetractionleverandtheinterlockswitch(Figure

31).

4.Tightentheinterlockswitchmountingfasteners

andcheckthegapagain.

Note:Thetractionlevermustnotcontactthe

switch.

5.Engagethetractionleverandverifythatthe

switchlosescontinuity.

Note:Replacetheswitchifnecessary.

29

Loading...

Loading...