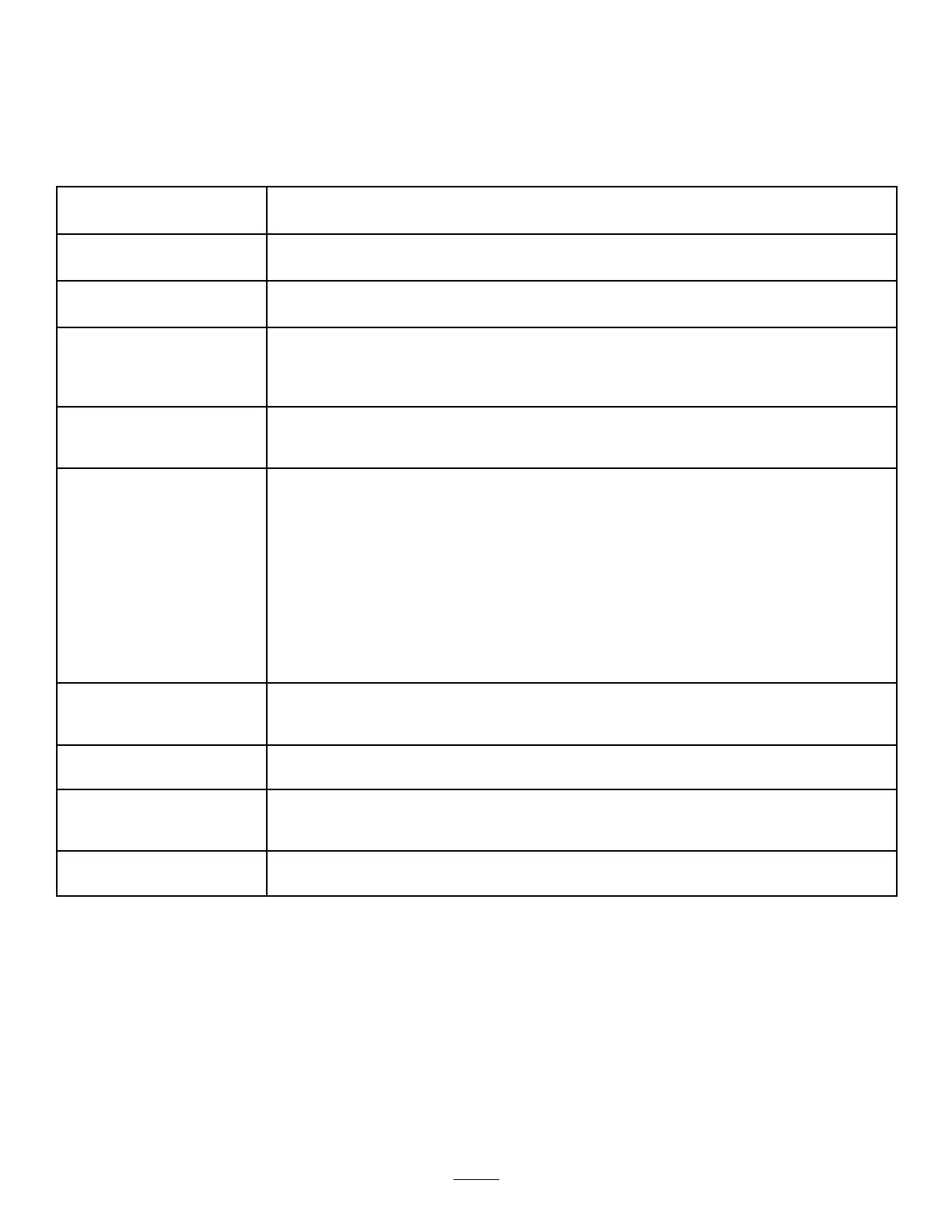

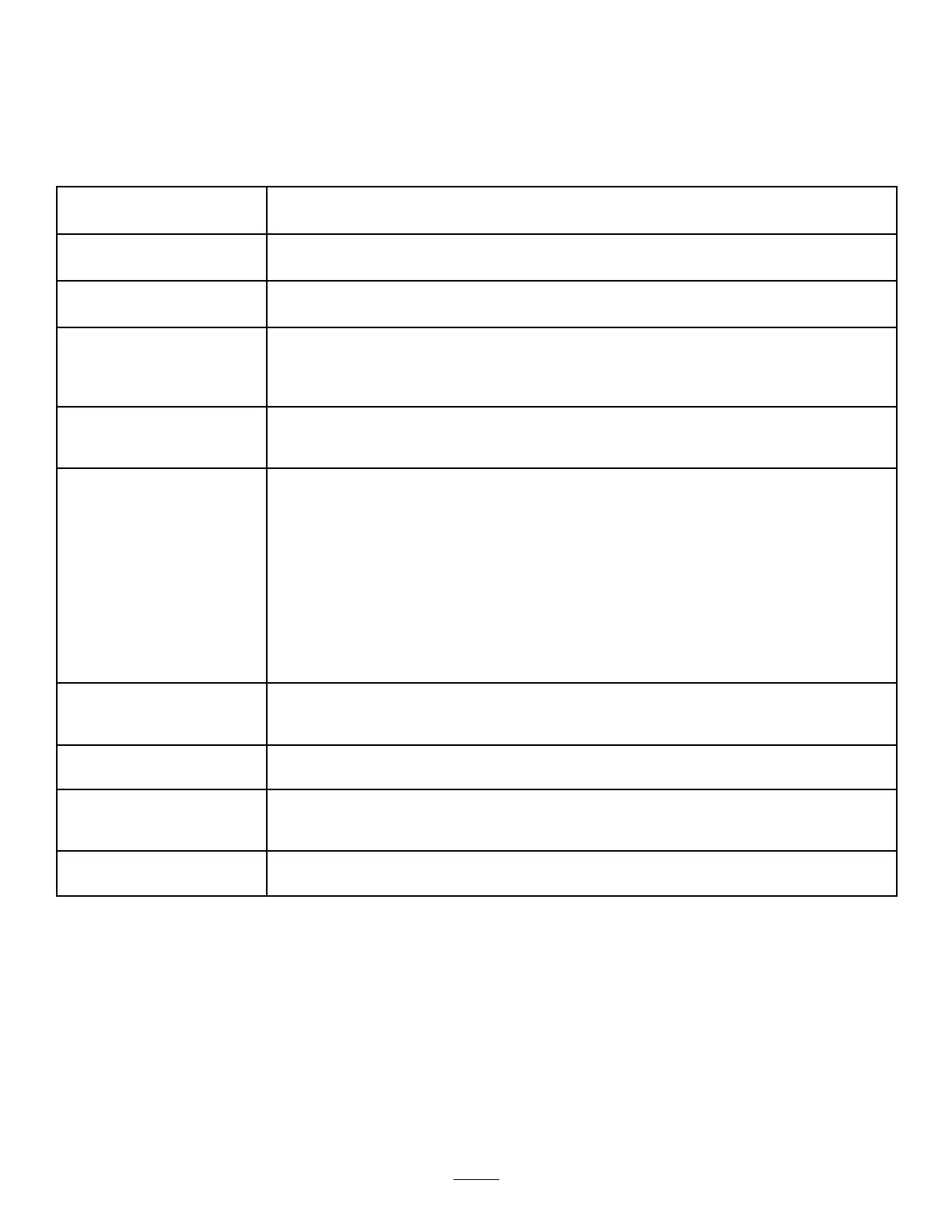

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Aftertherst8operating

hours

•Changetheengineoil.

•Checktheconditionandtensionofthedrivebelt.

Aftertherst25operating

hours

•Checkthefrontwheeltoe-inandfrontsuspension.

Beforeeachuseordaily

•Checktheengineoil.

•Checkthetirepressure.

•Checkthetransmissionoillevel.

•Checkthebrakeuidlevel.

Every50hours

•Changetheengineoil(twiceasofteninspecialoperatingconditions;referto

MaintainingtheVehicleunderSpecialOperatingConditions).

•Checkthebatterycableconnectionsforwearordamage.

Every100hours

•Greasethebearingsandbushings.

•Inspectandcleantheairlterelement(twiceasofteninspecialoperatingconditions;

refertoMaintainingtheVehicleunderSpecialOperatingConditions).

•Changetheoillter(twiceasofteninspecialoperatingconditions;referto

MaintainingtheVehicleunderSpecialOperatingConditions).

•ChecktheoperationoftheNeutralgearshiftposition.

•Inspecttheconditionandwearofthetires.

•Torquethewheellugnutsto45-65ft-lb(61-88N-m).

•Checkthefrontwheeltoe-inandfrontsuspension.

•Cleantheenginecoolingareas(twiceasofteninspecialoperatingconditions;refer

toMaintainingtheVehicleunderSpecialOperatingConditions).

•Inspectthebrakes.

Every200hours

•Replacetheairlterelement.

•Adjusttheparkingbrake.

•Checktheconditionandtensionofthedrivebelt.

Every400hours

•Inspectthefuellinesandconnections.

•Cleanandlubricatetheprimarydriveclutch.

Every800hours

•Replacethesparkplugs.

•Replacethefuellter.

•Changethetransaxleuid.

Yearly

•CompleteallyearlymaintenanceproceduresspeciedintheEngineOperator’s

Manual.

Important:Refertoyour

Engine Operator’ s Man ual

foradditionalmaintenanceprocedures.

26

Loading...

Loading...