CoolingSystem

Maintenance

CleaningtheEngineCooling

Areas

Cleantherotatingscreen,coolingns,andexternal

surfacesoftheengineevery100operatinghoursor

moreoftenunderextremelydustyanddirtyconditions.

Important:Operatingtheenginewithablocked

rotatingscreen,dirtyorpluggedcoolingns,or

coolingshroudsremovedwillcauseenginedamage

duetooverheating.

Important:Nevercleantheenginewith

pressurizedwaterbecausewatercouldcontaminate

thefuelsystem.

BrakeMaintenance

InspectingtheBrakes

Brakesareacriticalsafetycomponentofthevehicle.

Aswithallsafetycomponents,theyshouldbeclosely

inspectedatregularintervalstoensureoptimum

performanceandsafety.Thefollowinginspections

shouldbedoneevery100hours:

•Inspectthebrakeshoesforwearordamage.Ifthe

lining(brakepad)thicknessislessthan1/16inch

(1.6mm),thebrakeshoesshouldbereplaced.

•Inspectthebackingplateandothercomponents

forsignsofexcessivewearordeformation.Ifany

deformationisfound,theappropriatecomponents

mustbereplaced.

•Checkthebrakeuidlevel;refertoCheckingthe

BrakeFluidLevel.

CheckingtheBrakeFluid

Level

Thebrakeuidreservoirislledandshippedfromthe

factorywithDOT3brakeuid.Checkthelevelbefore

theengineisrststartedandevery8hoursordaily,

thereafter.

1.Parkthemachineonalevelsurface,settheparking

brake,turntheignitionoff,andremovethekey.

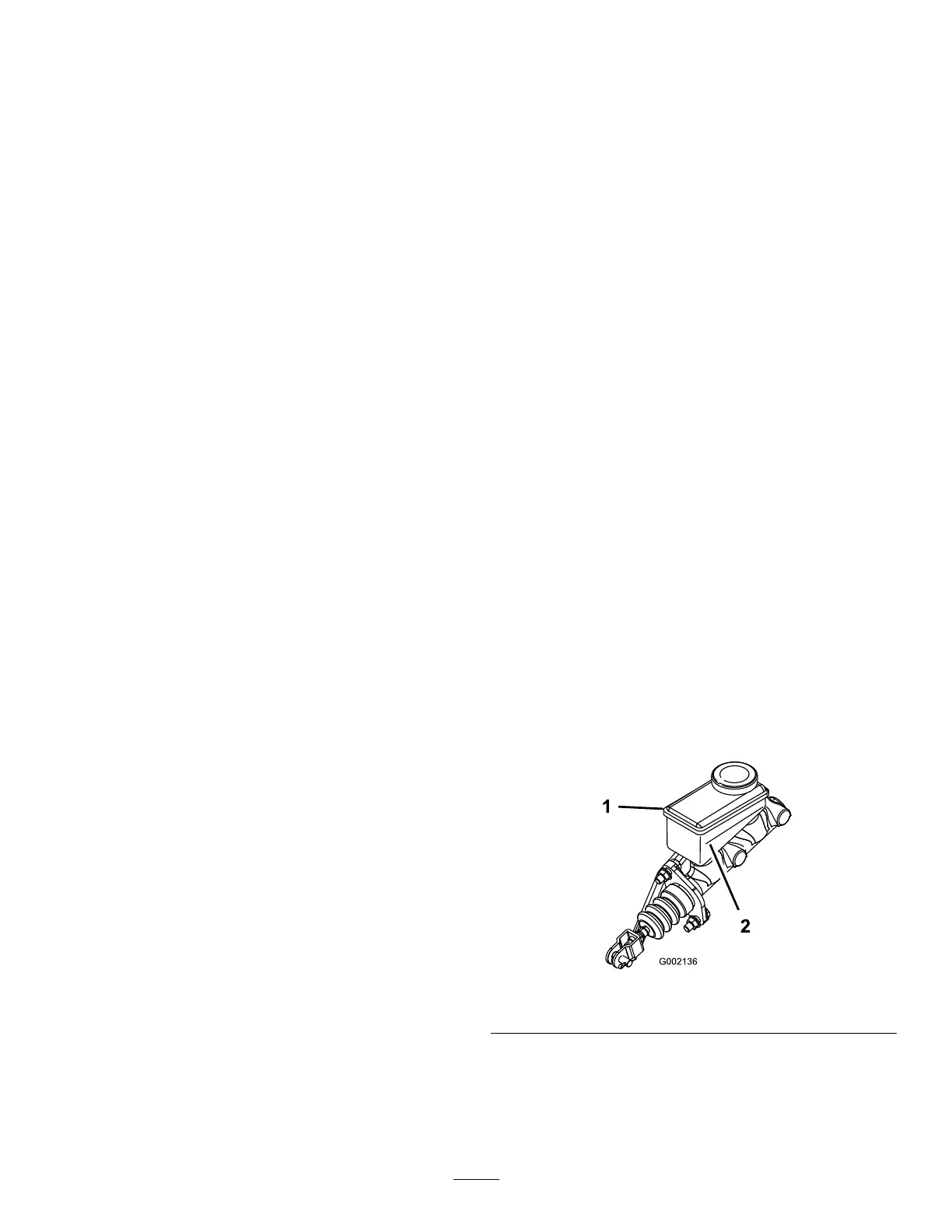

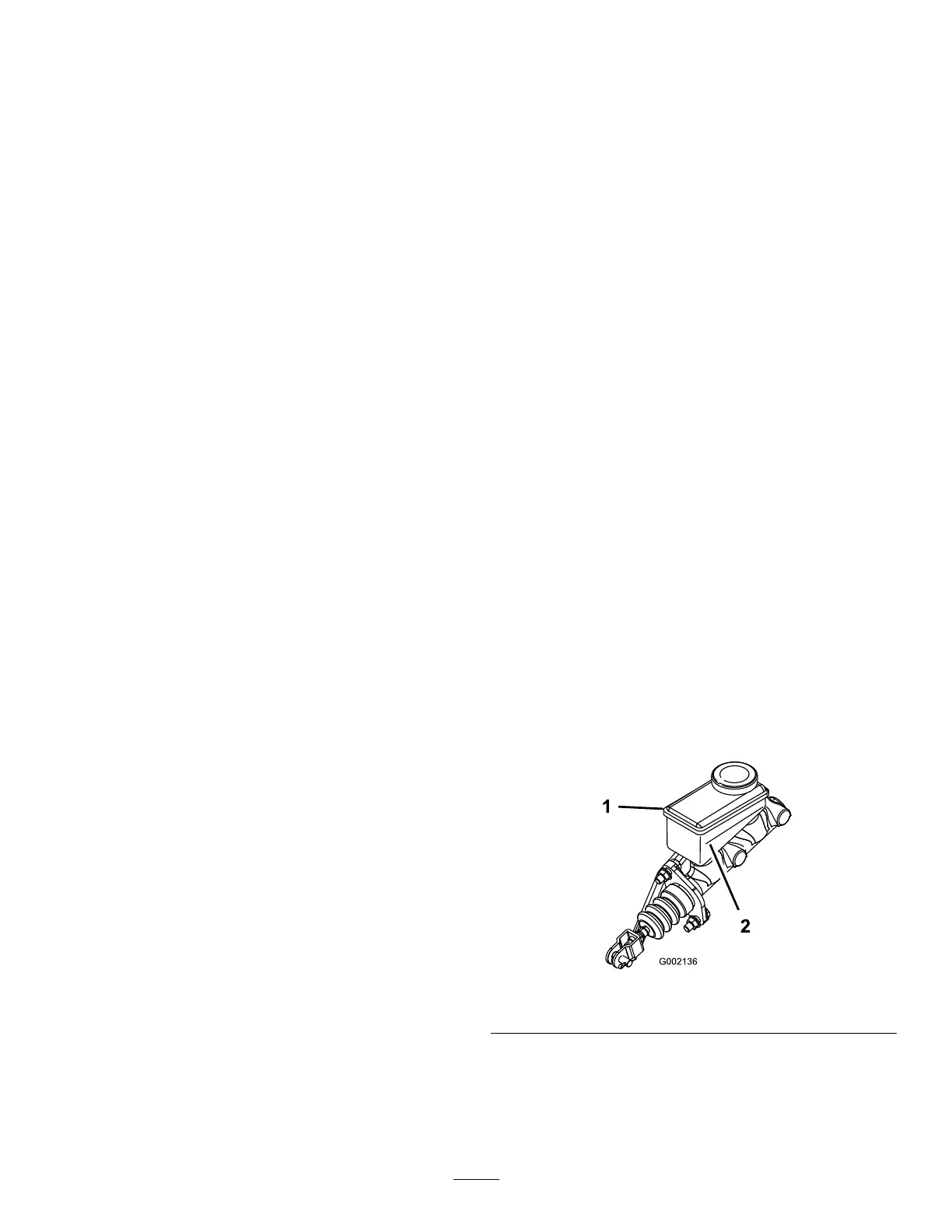

2.Lookatthesideofthereservoir.Thelevelshould

beabovetheMinimumline(Figure50).Iftheuid

levelislow,cleantheareaaroundthecap,remove

thecap,andllthereservoirtoabovetheMinimum

line.Donotoverll.

Figure50

1.Brakeuidreservoir

2.Minimumline

AdjustingtheParkingBrake

Checktheparkingbrakeadjustmentevery200hours.

1.Prytherubbercoveroffoftheparkingbrake.

37

Loading...

Loading...