Lubrication

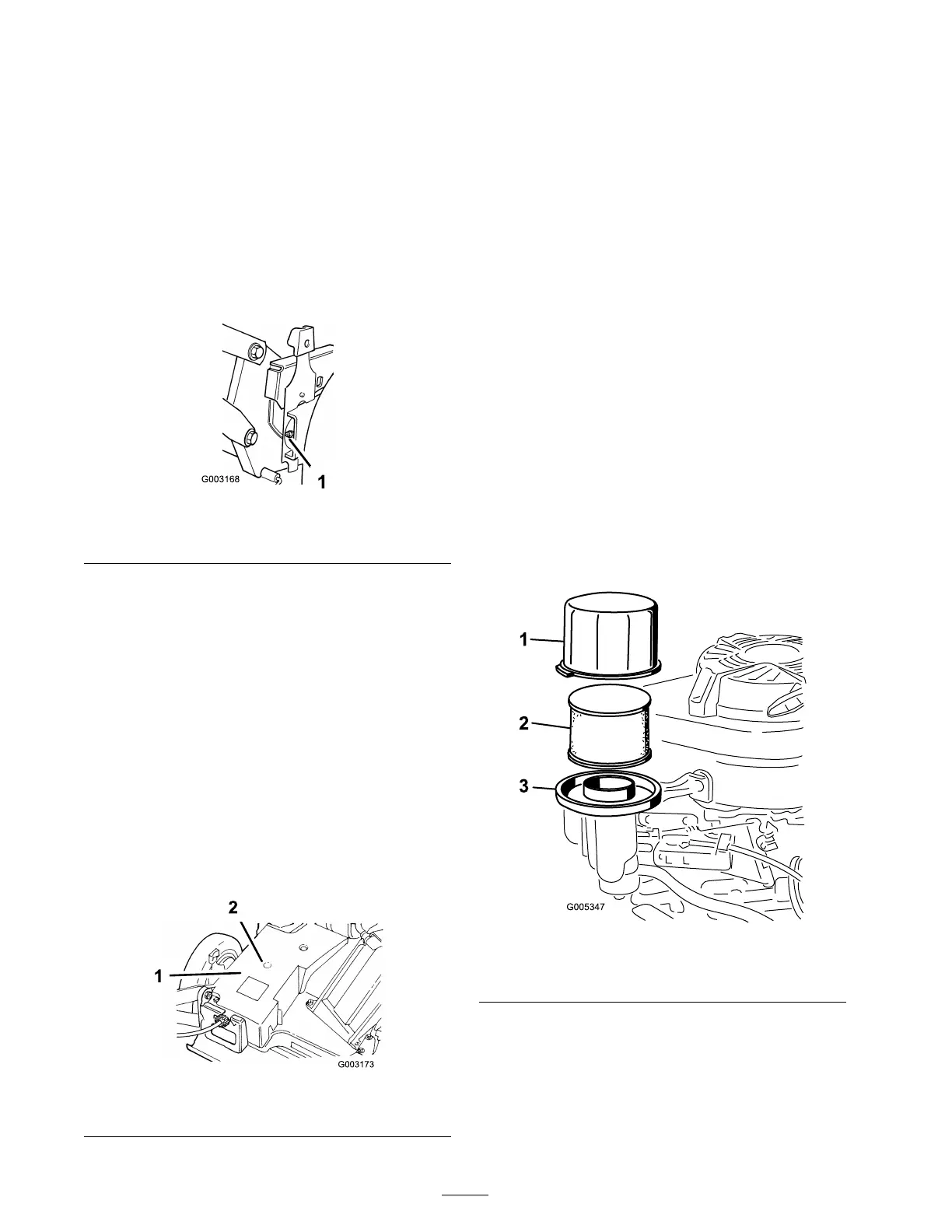

Lubricating the Pivot Arms

After ev er y 25 operating hours or when the season

ends , lubricate the pi v ot ar ms .

1. Mo v e the rear wheel cutting height lev ers to

the center setting .

2. Wipe the g rease fittings with a clean rag

( Figure 20 ).

Figure 20

1. Grease tting

3. Install a g rease gun onto the fitting and g ently

apply 2 or 3 pumps of #2 m ulti-pur pose

lithium-base g rease .

Important: Ex cessi v e g r ease pr essur e

may dama ge the seals.

Lubricating the Gear Case

After ev er y 100 operating hours , g rease the g ear

case .

1. R emo v e the g rass bag .

2. Install a g rease gun onto the fitting through the

belt co v er opening ( Figure 21 ).

Figure 21

1. Belt cover 2. Grease tting

3. Gently apply one to 2 pumps of #2

m ulti-pur pose lithium-base g rease .

4. Install the g rass bag .

Engine Maintenance

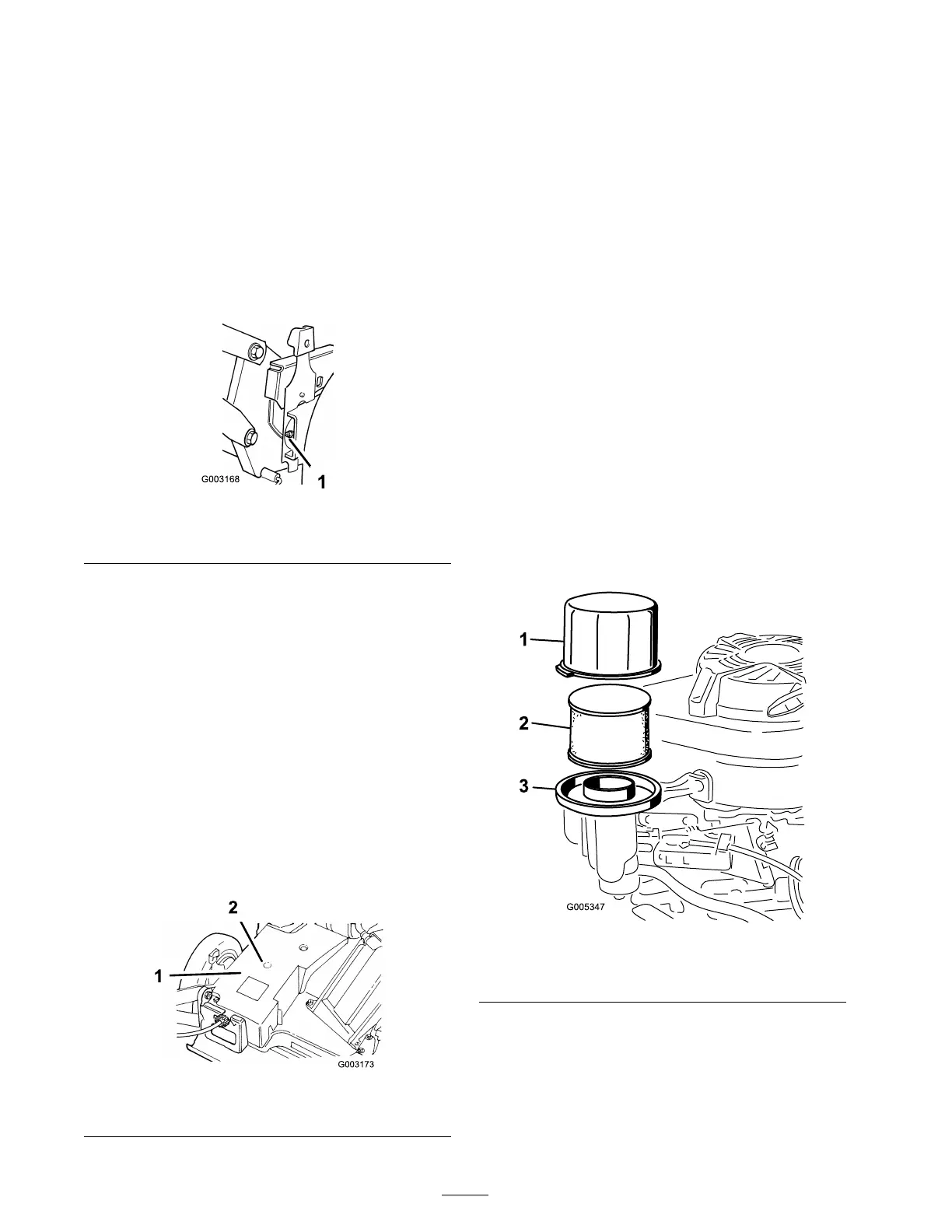

Servicing the Air Filter

Clean the foam pre-cleaner ev er y 25 operating

hours . R e place the paper air filter once ev er y

season or ev er y 300 operating hours; re place it

more frequently in dusty conditions .

Important: Do not operate the engine

without the air filter assembl y; extr eme engine

dama ge will occur .

1. Stop the engine and w ait for all mo ving par ts

to stop .

2. Disconnect the wire from the spark plug

( Figure 13 ).

3. R emo v e the co v er and clean it thoroughly

( Figure 22 ).

Figure 22

1. Cover

3. Air lter base

2. Paper air lter

4. R emo v e and inspect the paper air filter

( Figure 22 ), and discard it if it is ex cessi v ely

dir ty .

Important: Do not tr y to clean a paper

filter .

20

Loading...

Loading...