Maintenance

28

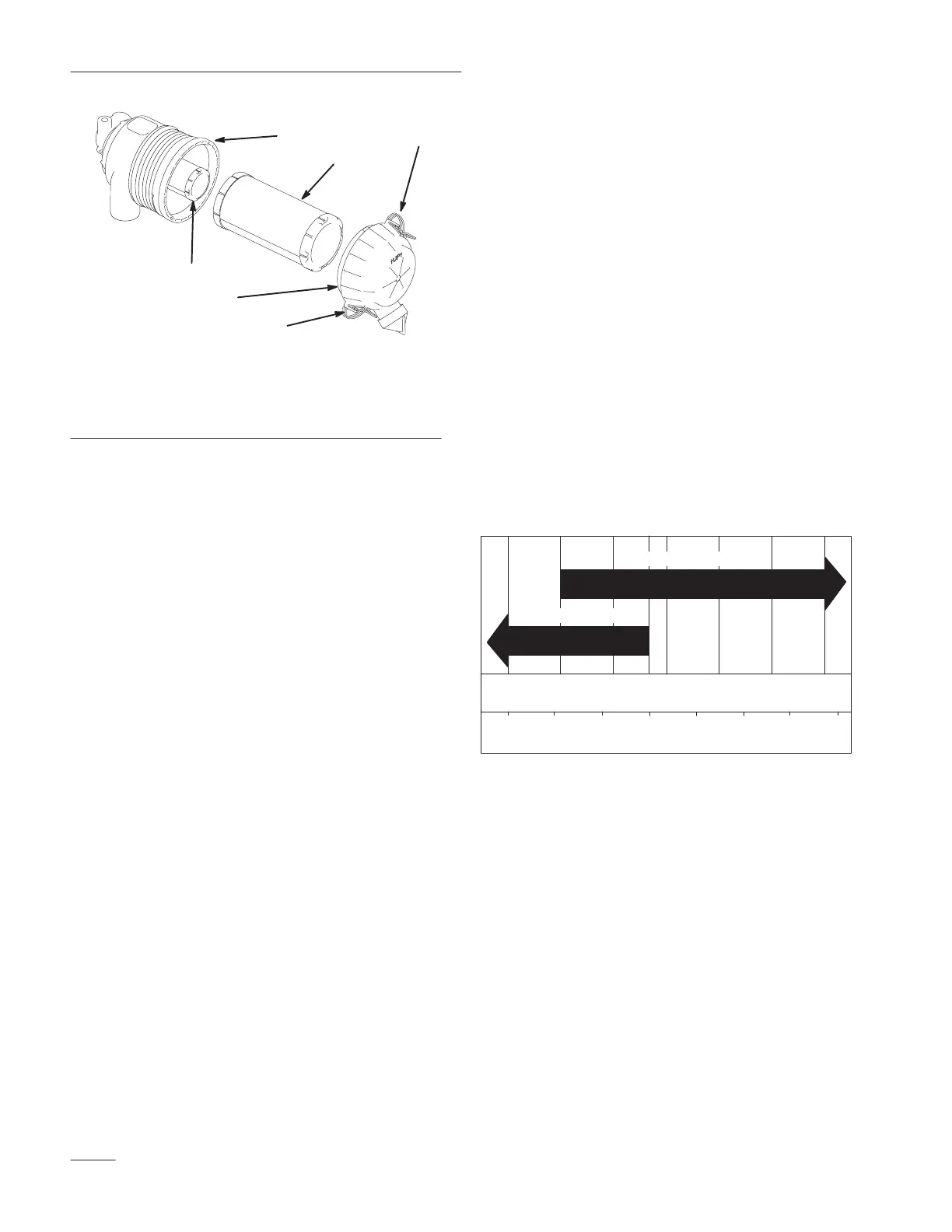

4

3

m–4387

5

1

2

1

Figure 19

1. Latches

2. Air

cleaner cover

3.

Air filter body

4.

Primary filter

5.

Safety filter

Cleaning the Primary Filter

Blow compressed air from the inside to the outside of

the primary filter.

IMPORTANT: Do not exceed 100 psi and

keep the hose at least 2 inches from the filter.

Installing the Filters

1. If installing new filters, check each filter for

shipping damage. Do not use a damaged filter.

2. If the safety filter is being replaced, carefully

slide it into the filter body (Fig. 19).

3. Carefully slide the primary filter over the safety

filter (Fig. 19). Ensure that it is fully seated by

pushing on the outer rim of the filter while

installing it.

IMPORTANT: Do not press on the soft inside

area of the filter.

4. Install the air cleaner cover with the side

indicated as UP facing up and secure the latches

(Fig. 19).

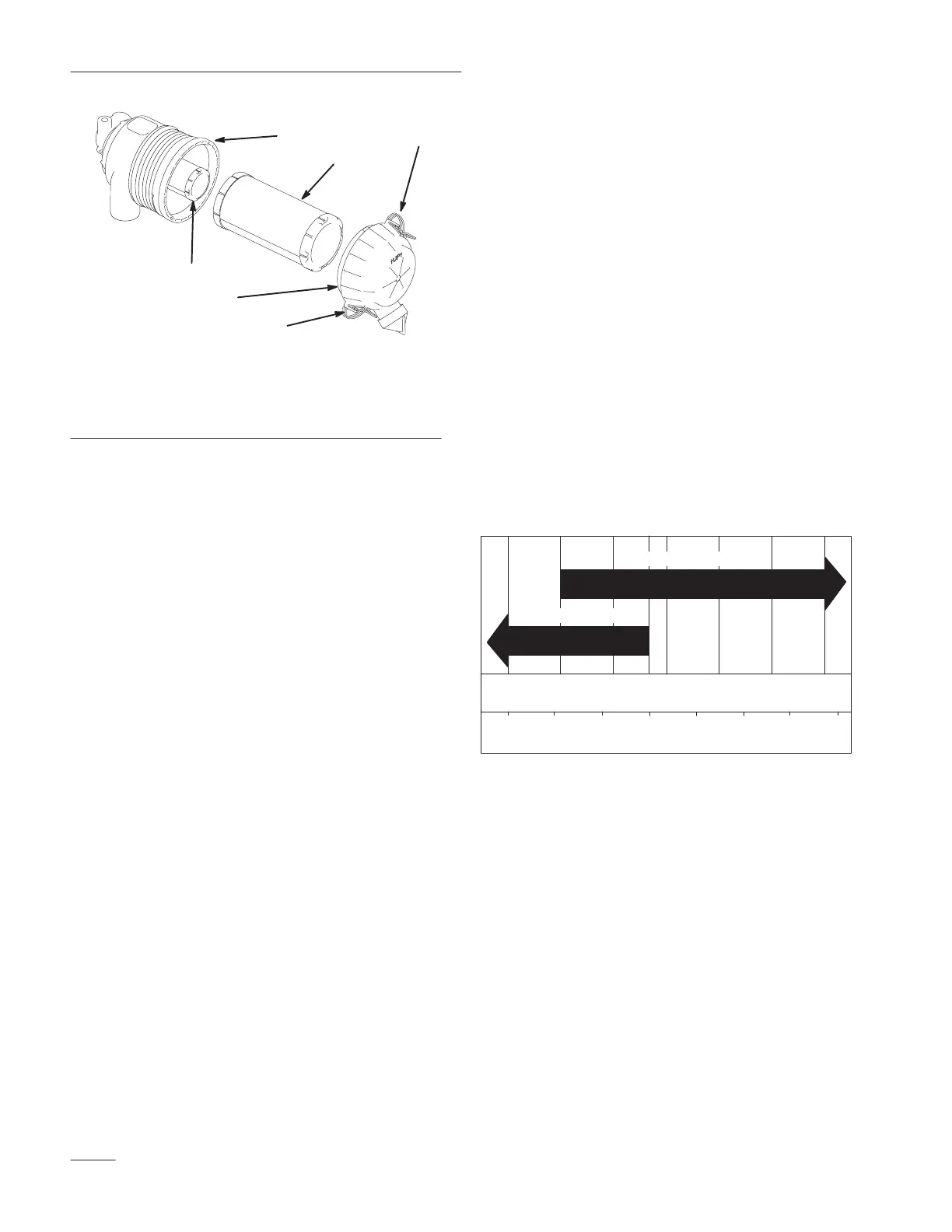

Servicing

the Engine Oil

Change oil after the first 50 operating hours and then

every 100 operating hours thereafter.

Note: Change oil more frequently when

operating conditions are extremely

dusty or sandy.

Oil Type: Detergent oil (API service SG or SH)

Crankcase Capacity: w/filter, 2.1 qt. (2 l)

Viscosity: See table below

F

–20 0 20

40 60

80 100

°

C

–30

°

–20 –10

01020

30 40

USE THESE SAE VISCOSITY OILS

32

5W–20, 5W–30

10W–30, 10W–40

Changing the Oil

1. Start the engine and let it run for five minutes.

This warms the oil so it drains better.

2. Park the traction unit so that the drain side is

slightly lower than the opposite side to ensure

that the oil drains completely.

Loading...

Loading...