Maintenance

32

0.030

in.

(0.76 mm)

2

3

1

m–3215

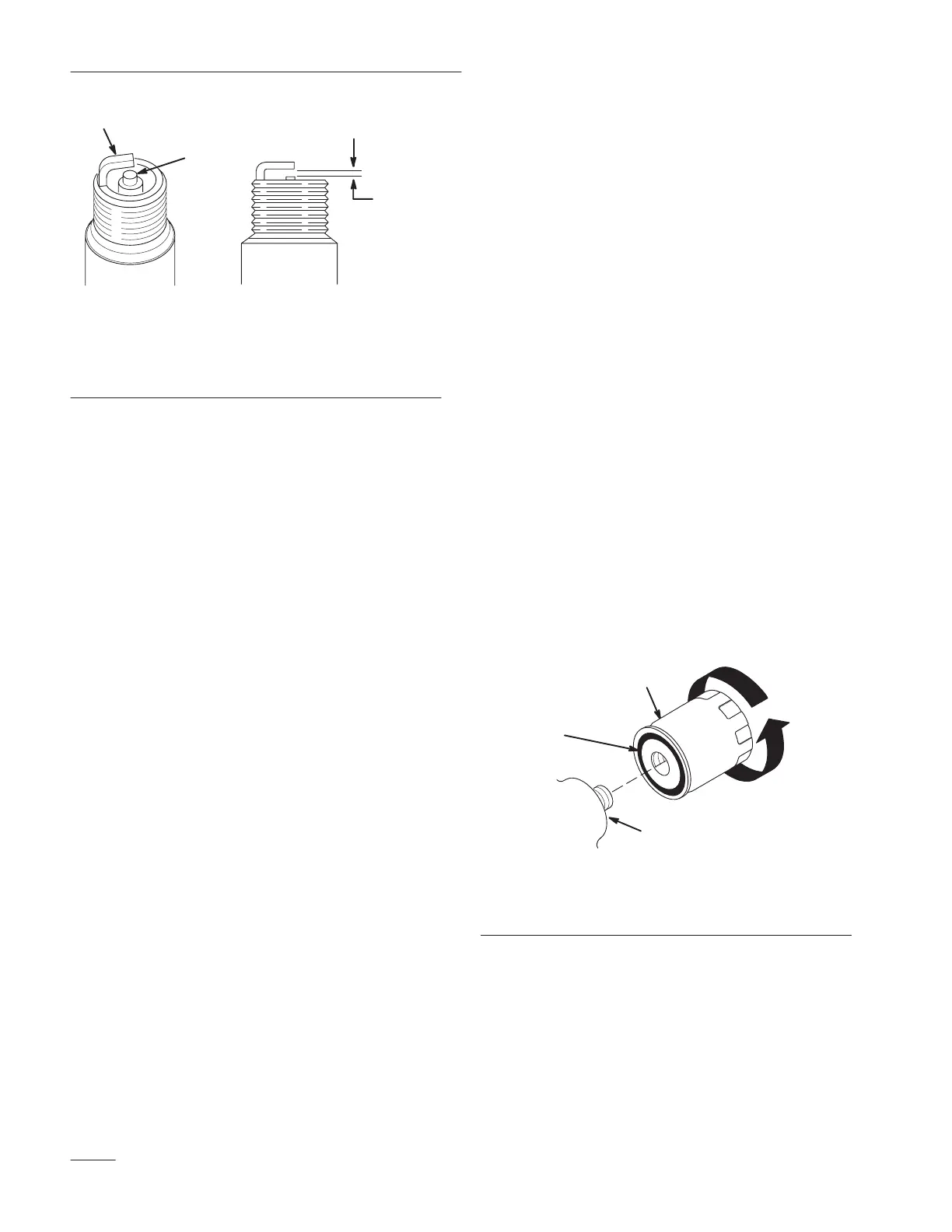

Figure

24

1. Center

electrode insulator

2.

Side electrode

3.

Air gap (not to scale)

Installing the Spark Plugs

1. Thread the spark plugs into the spark plug holes.

2. Tighten the spark plugs to 20 ft-lb (27 N.m).

3. Push the wires onto the spark plugs (Fig. 23).

Servicing

the Hydraulic

System

Replacing the Hydraulic Filter

Change the hydraulic filter:

• After the first 8 to 10 operating hours.

• After every 400 operating hours.

1. Position traction unit on a level surface.

2. Raise the loader arms and install the cylinder

locks; refer to Using the Cylinder Locks,

page 22.

3. Stop the engine and remove the key.

4. Remove the hood, refer to Removing the Hood,

page 26.

IMPORTANT: Do not substitute an

automotive oil filter or severe hydraulic

system damage may result.

5. Place a drain pan under the filter.

6. Remove the old filter and wipe the filter adapter,

gasket surface clean.

7. Apply a thin coat hydraulic fluid to the rubber

gasket on the replacement filter (Fig. 25).

8. Install the replacement hydraulic filter onto the

filter adapter. Tighten it clockwise until the

rubber gasket contacts the filter adapter, then

tighten the filter an additional 1/2 turn (Fig. 25).

9. Clean up any spilled fluid.

10. Start the engine and let it run for about two

minutes to purge air from the system.

11. Stop the engine and check for leaks.

12. Check the fluid level in the hydraulic tank (refer

to Checking the Hydraulic Fluid, page 15) and

add fluid to raise the level to mark on dipstick.

Do not over fill the tank.

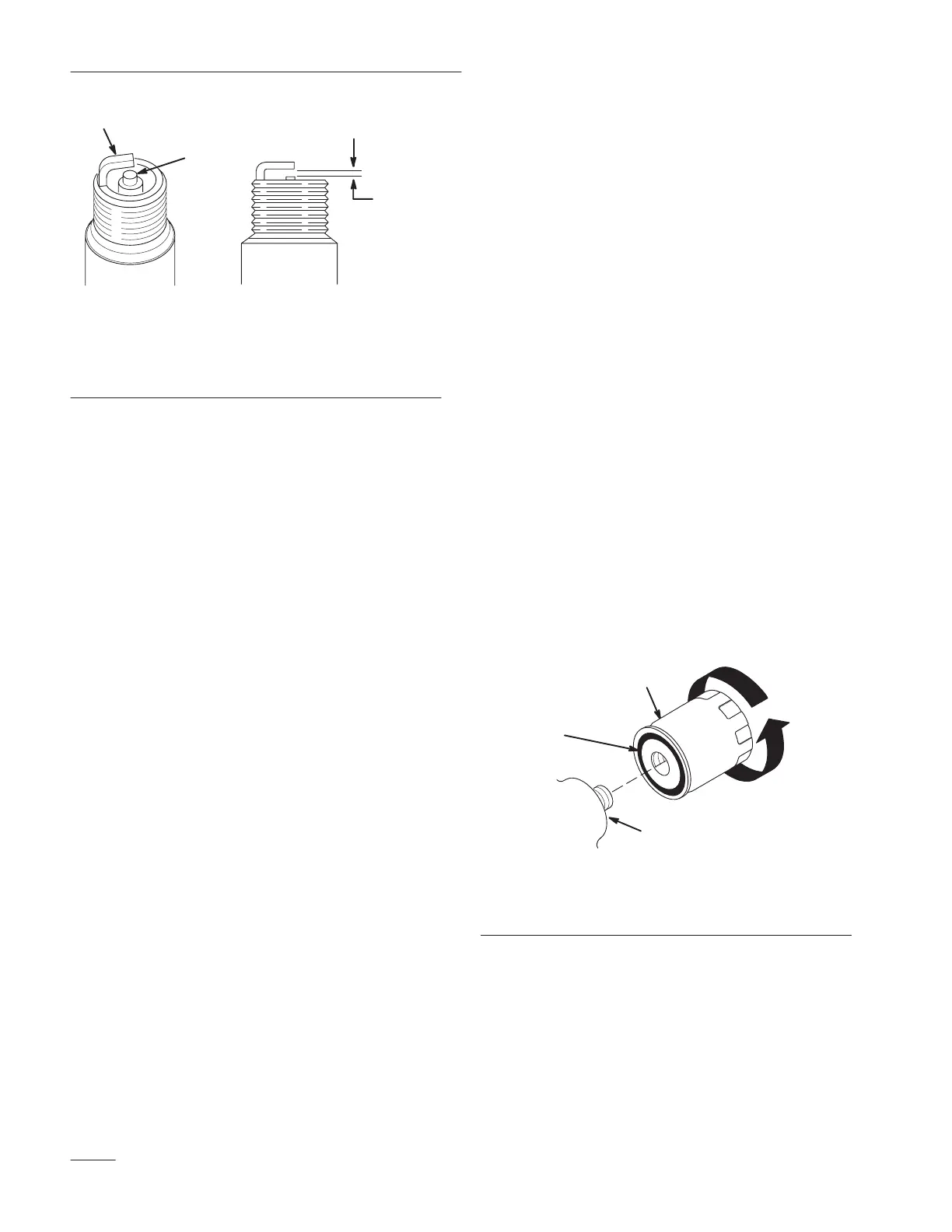

1

2

3

Figure 25

1. Hydraulic

filter

2. Gasket

3. Adapter

13. Install the hood; refer to Installing the Hood,

page 26.

Loading...

Loading...