Maintenance

31

POTENTIAL HAZARD

• Charging the battery pr

oduces gasses.

WHAT CAN HAPPEN

• Battery gasses can explode.

HOW TO AV

OID THE HAZARD

• Keep cigarettes, sparks, and flames away

from the battery.

Servicing

the Spark Plugs

Check the spark plugs after every 200 operating

hours. Ensure that the air gap between the center and

side electrodes is correct before installing each spark

plug. Use a spark plug wrench for removing and

installing the spark plugs and a gapping tool/feeler

gauge to check and adjust the air gap. Install new

spark plugs if necessary.

Type: Champion RC12YC (or equivalent) Air Gap:

0.030 in. (0.76 mm)

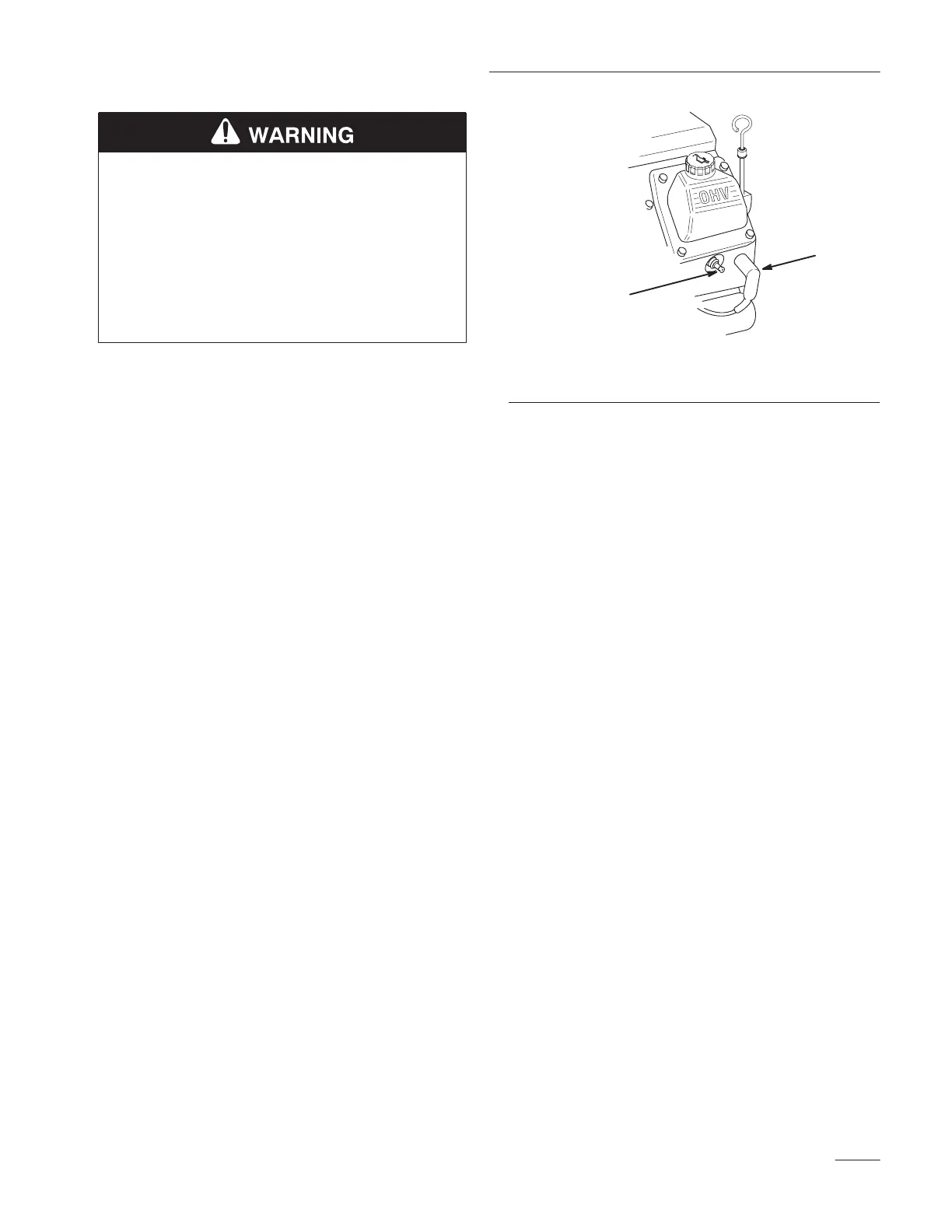

Removing the Spark Plugs

1. Lower the loader arms and stop the engine.

Remove the key.

2. Pull the wires off of the spark plugs (Fig. 23).

3. Clean around the spark plugs.

4. Remove the spark plugs and metal washers.

m–3876

1

2

Figure 23

1. Spark

plug wire

2.

Spark plug

Checking the Spark Plugs

1. Look at the center of the spark plugs (Fig. 24). If

you see light brown or gray on the insulator, the

engine is operating properly. A black coating on

the insulator usually means the air cleaner is

dirty.

IMPORTANT: Never clean the spark plugs.

Always r

eplace the spark plugs when they

have a black coating, worn electrodes, an oily

film, or cracks.

2. Check the gap between the center and side

electrodes (Fig. 24).

3. Bend the side electrode (Fig. 24) if the gap is not

correct.

Loading...

Loading...