CoolingSystem

Maintenance

CleaningtheAirIntakeScreen

ServiceInterval:Beforeeachuseordaily

Beforeeachuseremoveanybuild-upofgrass,dirt

orotherdebrisfromthecylinderandcylinderhead

coolingns,airintakescreenonywheelend,and

carburetor-governorleversandlinkage.Thiswillhelp

insureadequatecoolingandcorrectenginespeedand

willreducethepossibilityofoverheatingandmechanical

damagetotheengine.

CleaningtheCoolingSystem

ServiceInterval:Every100hours—Checkandclean

enginecoolingnsandshrouds.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

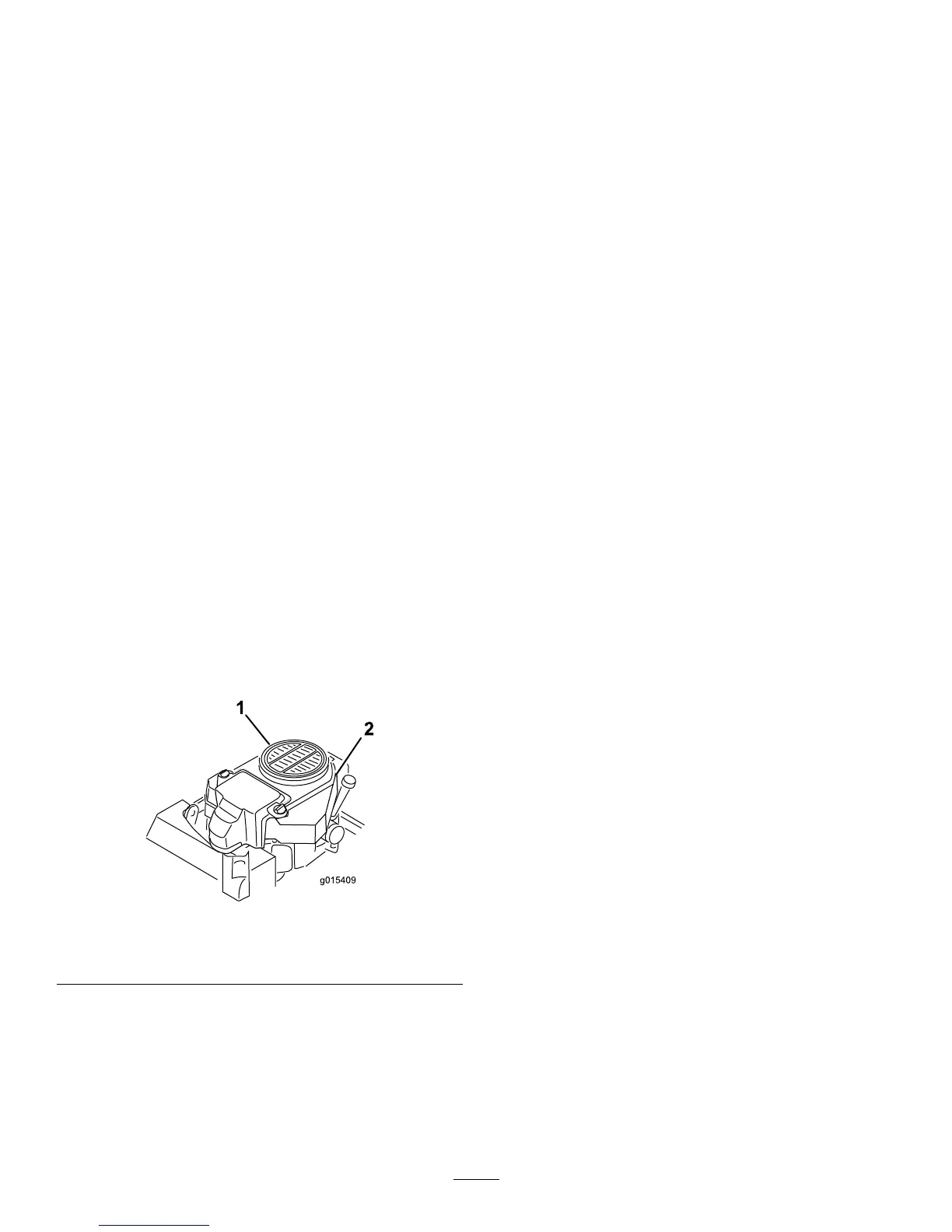

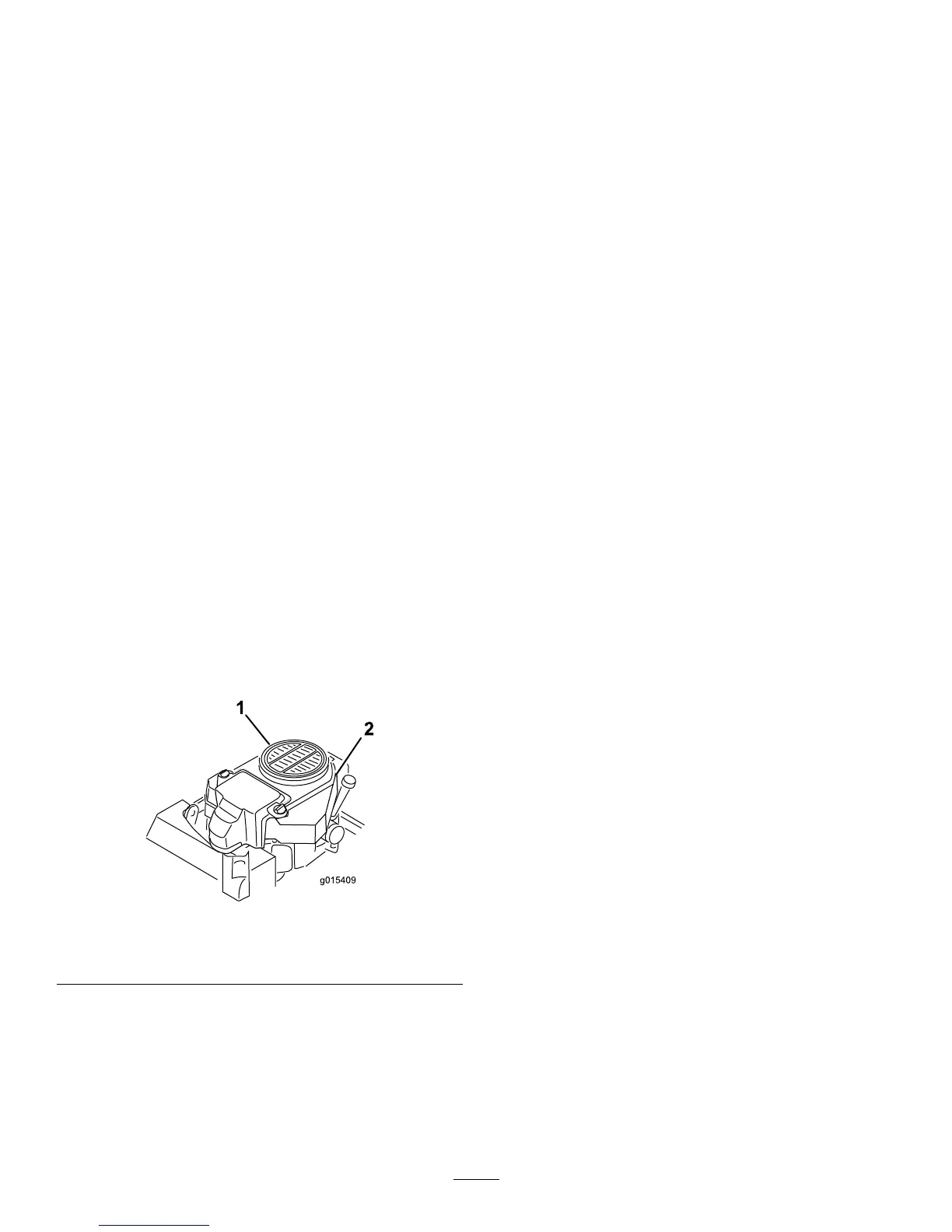

3.Removetheairintakescreenandfanhousing

(

Figure61).

4.Cleanthedebrisandgrassfromtheengineparts.

5.Installairintakescreen,recoilstarterandfanhousing

(

Figure61).

Figure61

1.Guardandengineair

intakescreen

2.Fanhousing

BrakeMaintenance

ServicingtheBrake

Beforeeachuse,checkbrakesonbothalevelsurface

andslope.

Alwayssettheparkingbrakewhenyoustopthemachine

orleaveitunattended.Iftheparkingbrakedoesnot

holdsecurely,anadjustmentisrequired.

CheckingtheParkingBrake

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurface,disengagethe

PTO.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Releasethebrake.Thebrakebarsshouldliftoff

thetiresandthehandlevershouldtravelforwardto

theendoftheslotinthecontrolpanel.Adjustthe

brakeifneeded.

4.Engagethebrakeleveruntilthebrakebarsrst

contactthetire(

Figure62).

5.Measurethegapfromthefrontofthehandlever

totheendoftheslotinthecontrolpanelwhenthe

brakebarcontactsthetire.Thismeasurementneeds

tobe3/4inch(19mm).Adjustthebrakeifneeded

(

Figure62).

44

Loading...

Loading...