g201858

Figure122

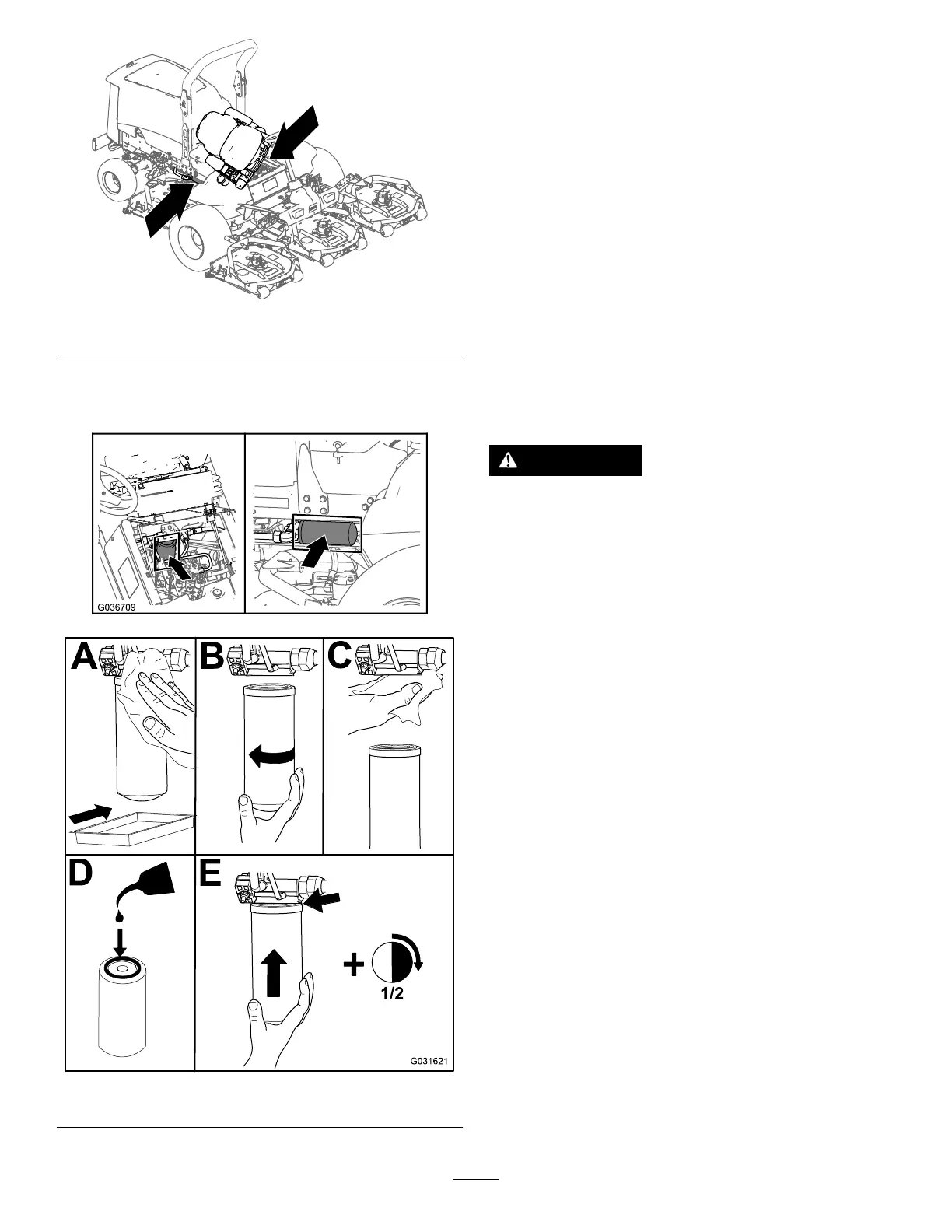

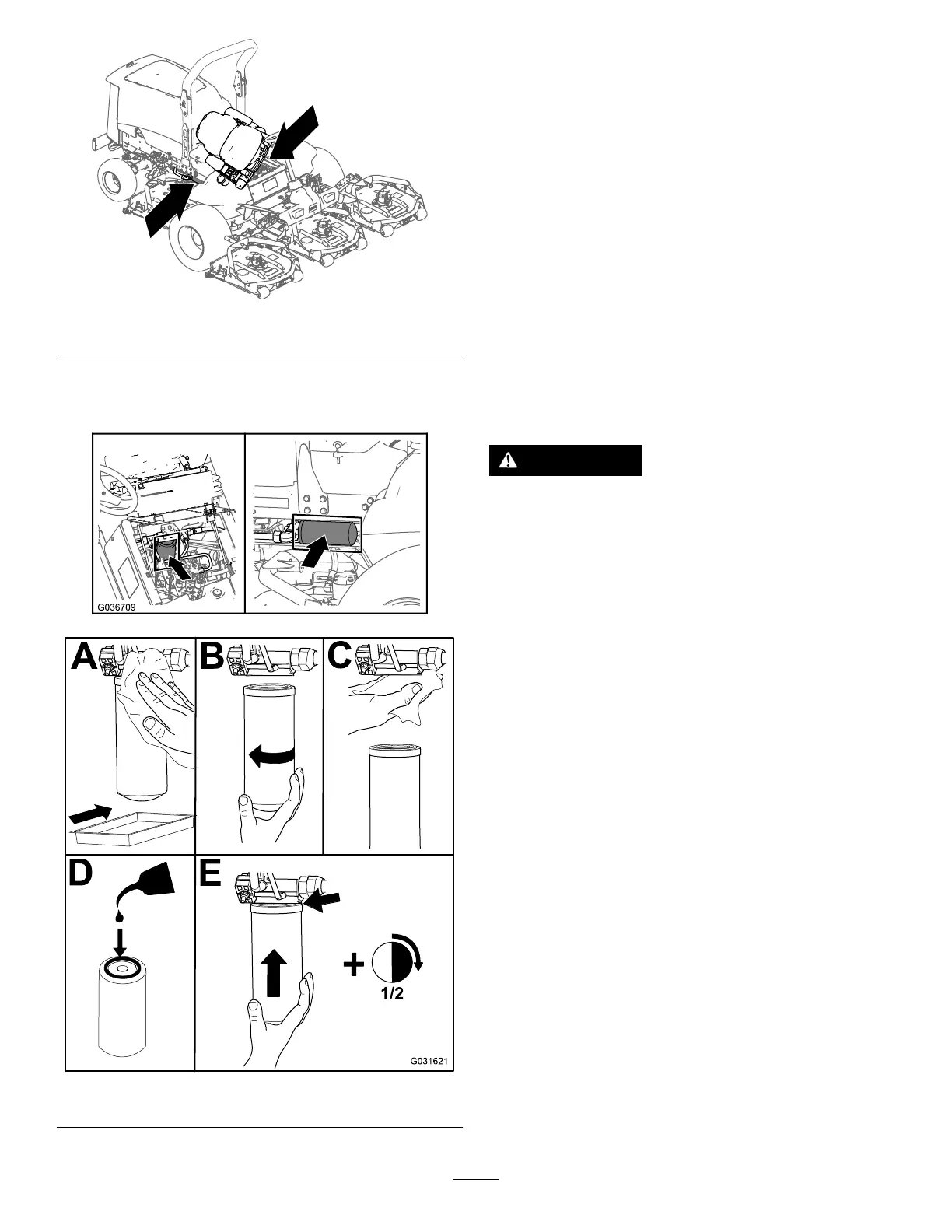

2.Replacethechargehydrauliclteratthe

hydraulicliftcompartmentasshowninFigure

123.

g036709

g031621

Figure123

3.Lowerandsecuretheoperator’sseat.

4.Replacethereturnlterattherightsideofthe

machine(Figure123).

5.Starttheengineandletitrunforabout2minutes

topurgeairfromthesystem.Shutofftheengine

andcheckforleaks.

CheckingtheHydraulic

LinesandHoses

ServiceInterval:Beforeeachuseordaily

Every2years

Inspectthehydrauliclinesandhosesdailyfor

leaks,kinkedlines,loosemountingsupports,wear,

loosettings,weatherdeterioration,andchemical

deterioration.Makeallnecessaryrepairsbefore

operatingthemachine.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Seekimmediatemedicalhelpifuidis

injectedintoskin.

•Makesurethatallhydraulic-uidhoses

andlinesareingoodconditionandall

hydraulicconnectionsandttingsaretight

beforeapplyingpressuretothehydraulic

system.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthateject

high-pressurehydraulicuid.

•Usecardboardorpapertondhydraulic

leaks.

•Safelyrelieveallpressureinthehydraulic

systembeforeperforminganyworkonthe

hydraulicsystem.

83

Loading...

Loading...