CuttingUnitMaintenance

RemovingtheCuttingUnits

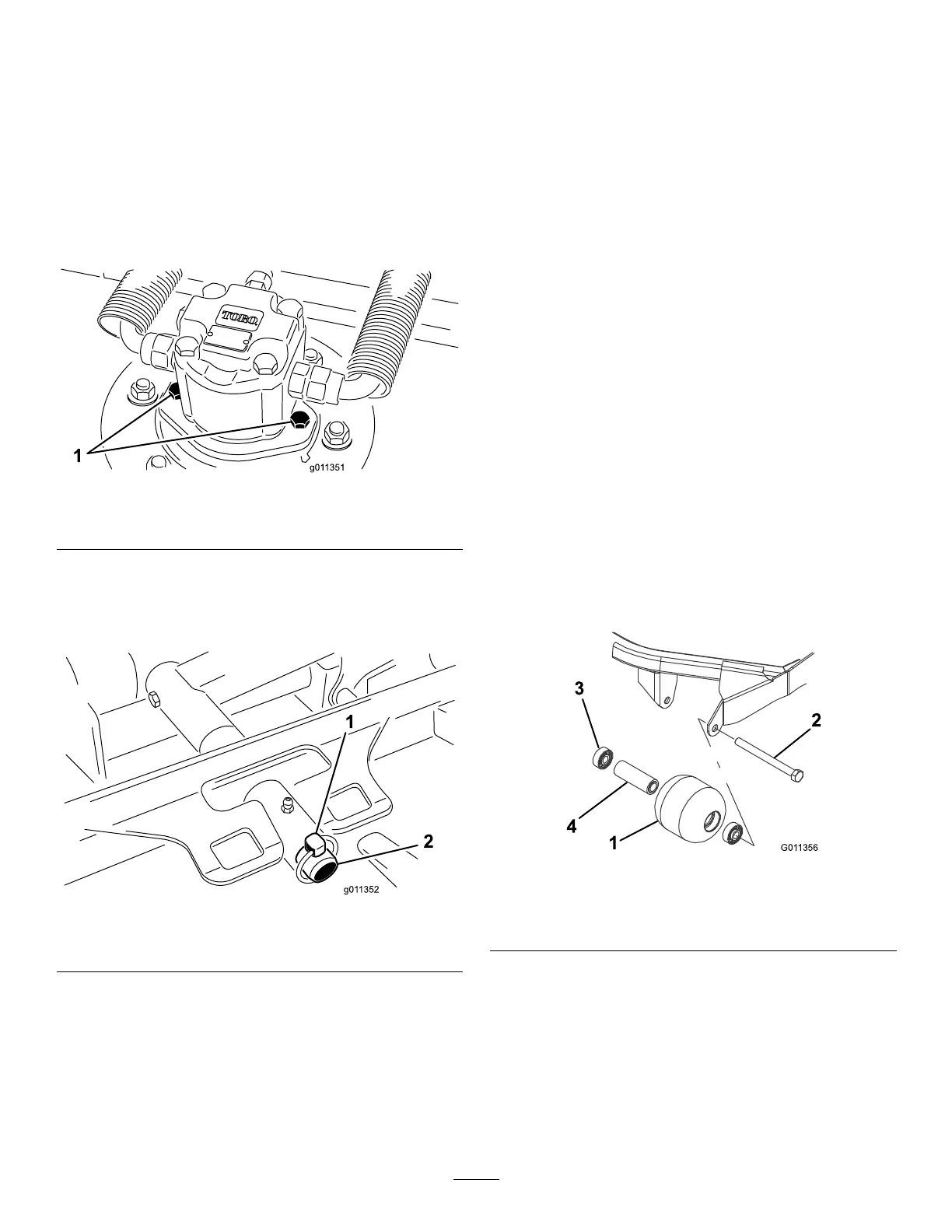

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,lowerthecuttingunits,shutoff

theengine,andremovethekey.

2.Disconnectandremovethehydraulicmotor

fromthecuttingunit(Figure124).Coverthetop

ofthespindletopreventcontamination.

g011351

Figure124

1.Motor-mountingscrews

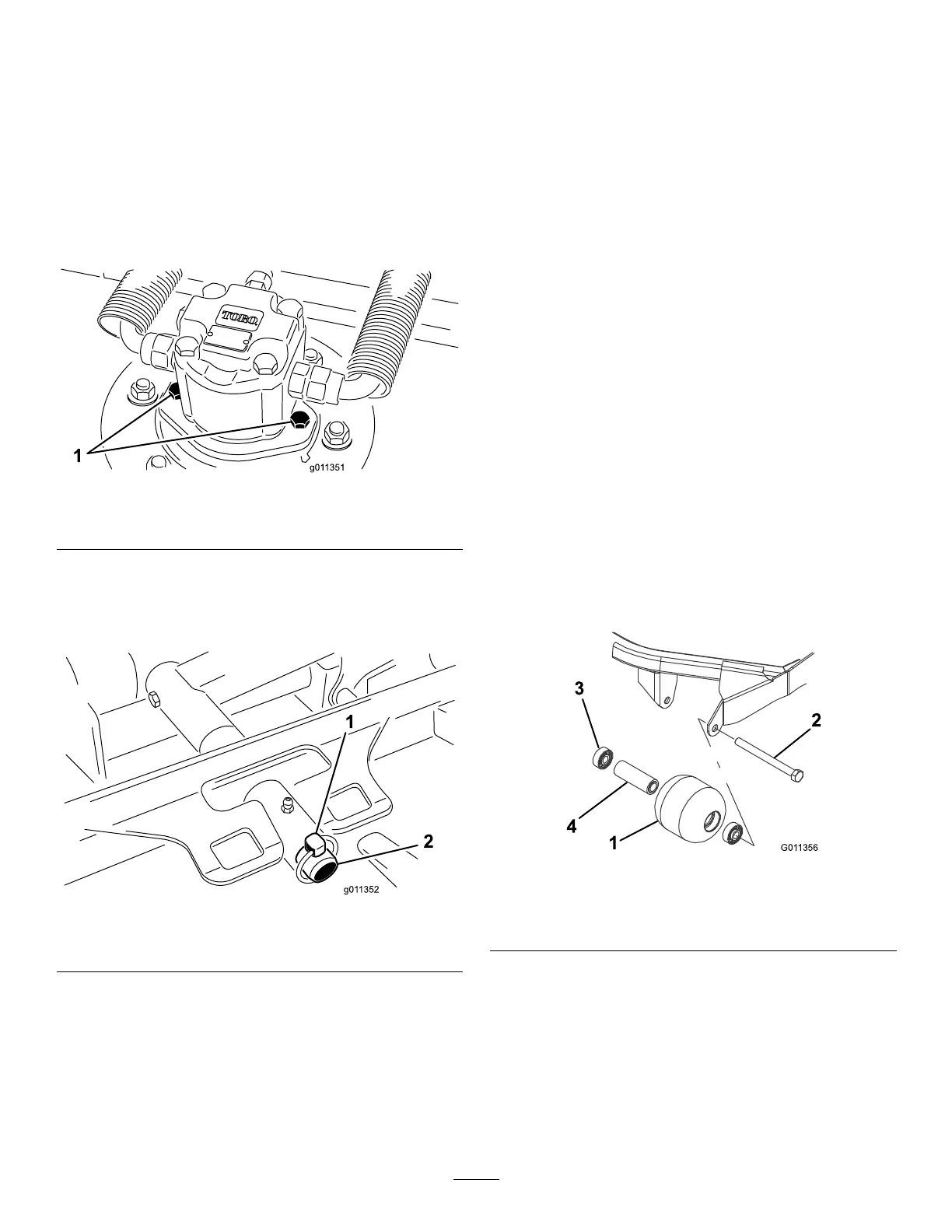

3.Removethelynchpin(forGroundsmaster4500

machines)orretainingnut(forGroundsmaster

4700machines)securingthecuttingunit-carrier

frametothelift-armpivotpin(Figure125).

g011352

Figure125

1.Lynchpin

2.Lift-armpivotpin

4.Rollthecuttingunitawayfromthemachine.

InstallingtheCuttingUnits

1.Movethecuttingunitintopositioninfrontofthe

machine.

2.Slidethecuttingunit-carrierframeontothe

lift-arm-pivotpin(Figure125).Securethe

cuttingunittothepinwiththelynchpin(for

Groundsmaster4500machines)orretainingnut

(forGroundsmaster4700machines).

3.Installthehydraulicmotortothecuttingunit

(Figure124).MakesurethattheO-ringisin

positionandnotdamaged.

4.Greasethespindle.

ServicingtheFrontRoller

Inspectthefrontrollerforwear,excesswobble,or

binding.Serviceorreplacetherollerorcomponentsif

anyoftheseconditionsexist.

DisassemblingtheFrontRoller

1.Removetheroller-mountingbolt(Figure126).

2.Insertapunchthroughtheendoftheroller

housinganddrivetheoppositebearingoutby

alternatingtapstotheoppositesideofinner

bearingrace.Thereshouldbea1.5mm(0.060

inch)lipofinnerraceexposed.

g011356

Figure126

1.Frontroller3.Bearing

2.Mountingbolt4.Bearingspacer

3.Pushthesecondbearingoutinpress.

4.Inspecttherollerhousing,bearings,andbearing

spacerfordamage(Figure126).Replaceany

damagedcomponentsandassemblethem.

84

Loading...

Loading...