AssemblingtheFrontRoller

1.Presstherstbearingintotherollerhousing

(Figure126).Pressontheouterraceonlyor

equallyontheinnerandouterrace.

2.Insertthespacer(Figure126).

3.Pressthesecondbearingintotherollerhousing

(Figure126).Pressingequallyontheinner

andouterraceuntiltheinnerracecontactsthe

spacer.

4.Installtherollerassemblyintothecutting-unit

frame.

5.Verifythatthereisnomorethana1.5mm(0.060

inch)gapbetweenrollerassemblyandtheroller

mountbracketsofthecutting-unitframe.Ifthere

isagapover1.5mm(0.060inch),installenough

5/8-inchdiameterwasherstotakeuptheslop.

Important:Securingtherollerassembly

withagaplargerthan1.5mm(0.060inch)

createsasideloadonthebearingandcan

leadtoprematurebearingfailure

6.Torquethemountingboltto108N∙m(80ft-lb).

BladeMaintenance

BladeSafety

•Inspectthebladeperiodicallyforwearordamage.

•Usecarewhencheckingtheblades.Wrapthe

bladesorweargloves,andusecautionwhen

servicingtheblades.Onlyreplaceorsharpenthe

blades;neverstraightenorweldthem.

•Onmulti-bladedmachines,takecareasrotating

onebladecancauseotherbladestorotate.

ServicingtheBladePlane

Thecuttingunitcomesfromthefactorypresetat5

cm(2inches)heightofcutandbladerakeof7.9mm

(0.310inch).Theleftandrightheightsarealsopreset

towithin±0.7mm(0.030inch)oftheother.

Thecuttingunitisdesignedtowithstandblade

impactswithoutdeformationofthechamber.Ifthe

bladestrikesasolidobject,inspectthebladefor

damageandthebladeplaneforaccuracy.

InspectingtheBladePlane

1.Removethehydraulicmotorfromthecuttingunit

andremovethecuttingunitfromthemachine.

2.Useahoist(orminimumof2people)andplace

thecuttingunitonaattable.

3.Mark1endofthebladewithapaintpenor

marker.Usethisendofthebladetocheckall

heights.

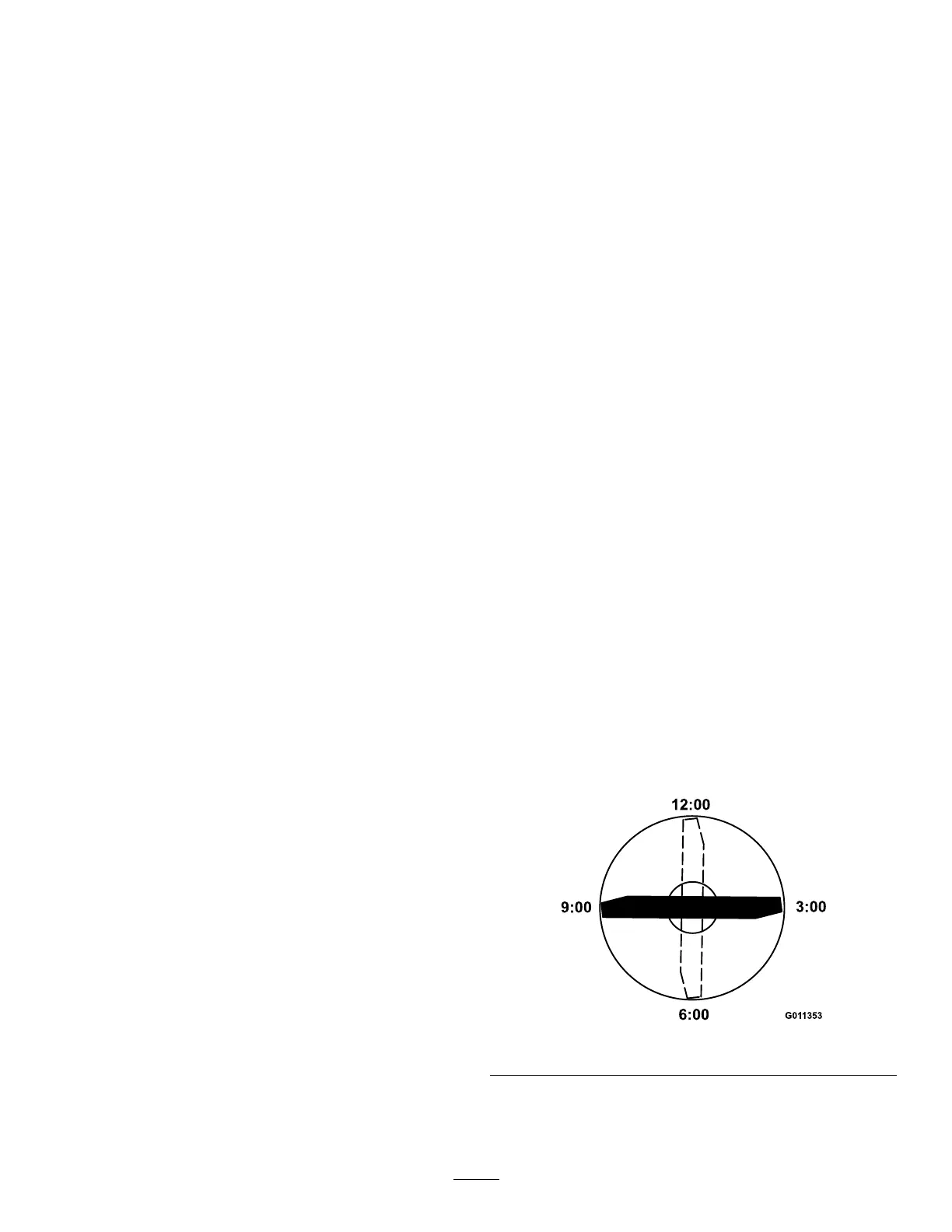

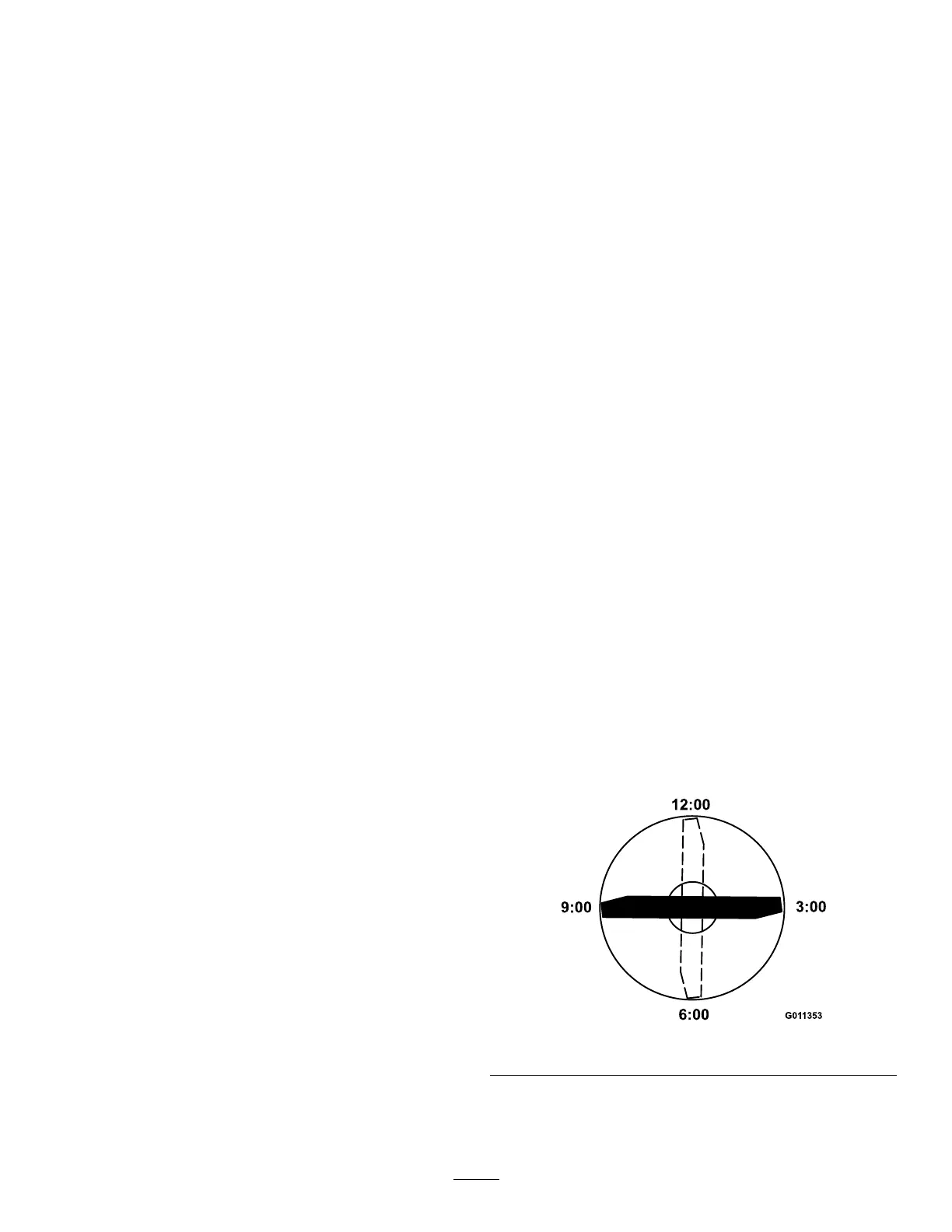

4.Positionthecuttingedgeofthemarkedendof

thebladeat12o’clock(straightaheadinthe

directionofmowing)(Figure127)andmeasure

heightfromtabletocuttingedgeofblade.

g011353

Figure127

5.Rotatethemarkedendofthebladetothe3and

9o’clockpositions(Figure127)andmeasure

theheights.

85

Loading...

Loading...