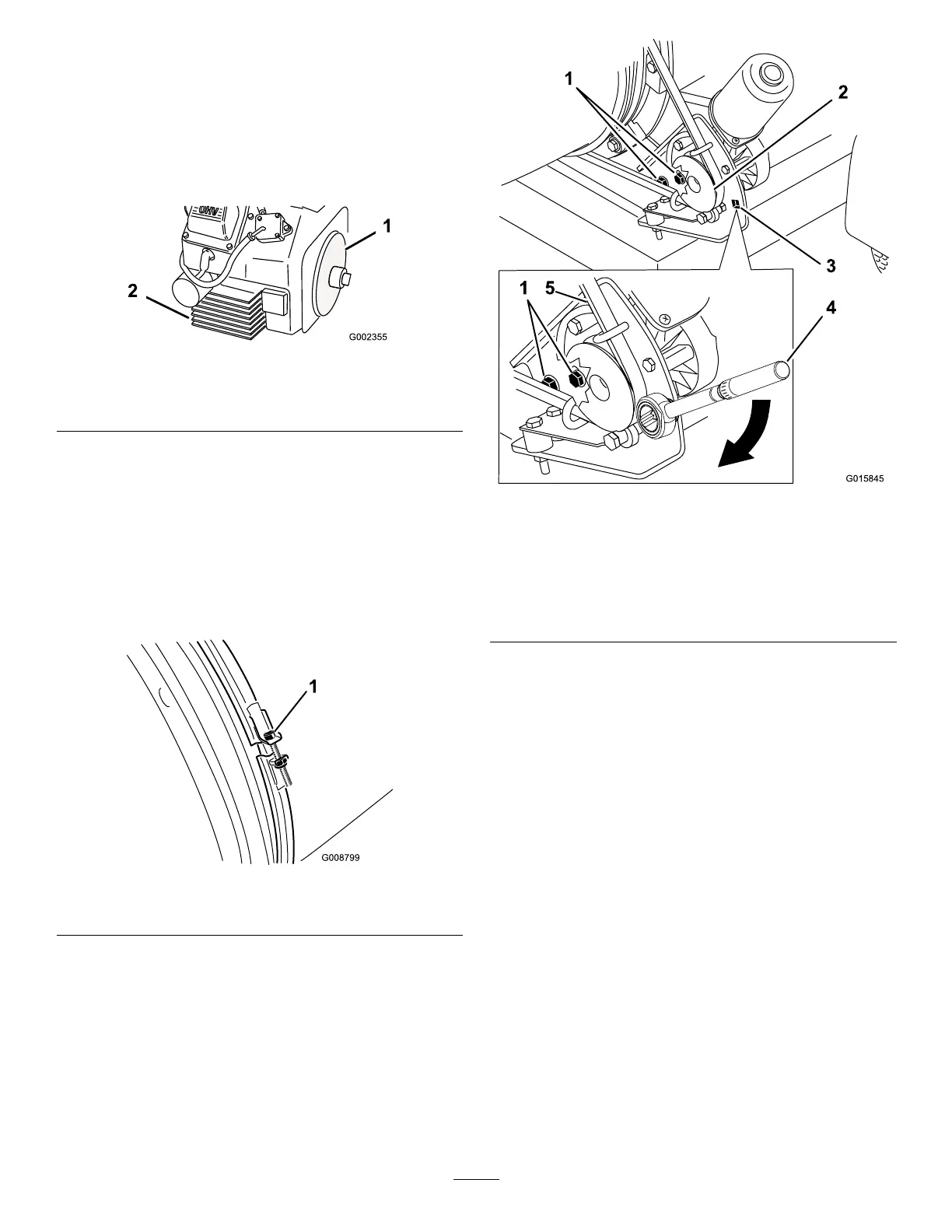

CleaningtheEngineScreen

andtheOilCooler

ServiceInterval:Beforeeachuseordaily

Beforeeachuse,checkandcleantheenginescreenand

oilcooler.Removeanybuildupofgrass,dirtorother

debrisfromtheoilcoolerandenginescreen(

Figure28).

Figure28

1.Enginescreen

2.Oilcooler

CheckingtheNozzleClamp

ServiceInterval:Beforeeachuseordaily

Checkthenozzleclamp(Figure29)dailytoassureitis

tight.Ifthenozzleisdraggedoverobstaclesorthrough

lowareasintheterrainitcouldbeknockedloosefrom

theclamp.Torquetheclampfastenersto45-50in-lb

(5.1-5.7N-m).

Figure29

1.Nozzleclamp

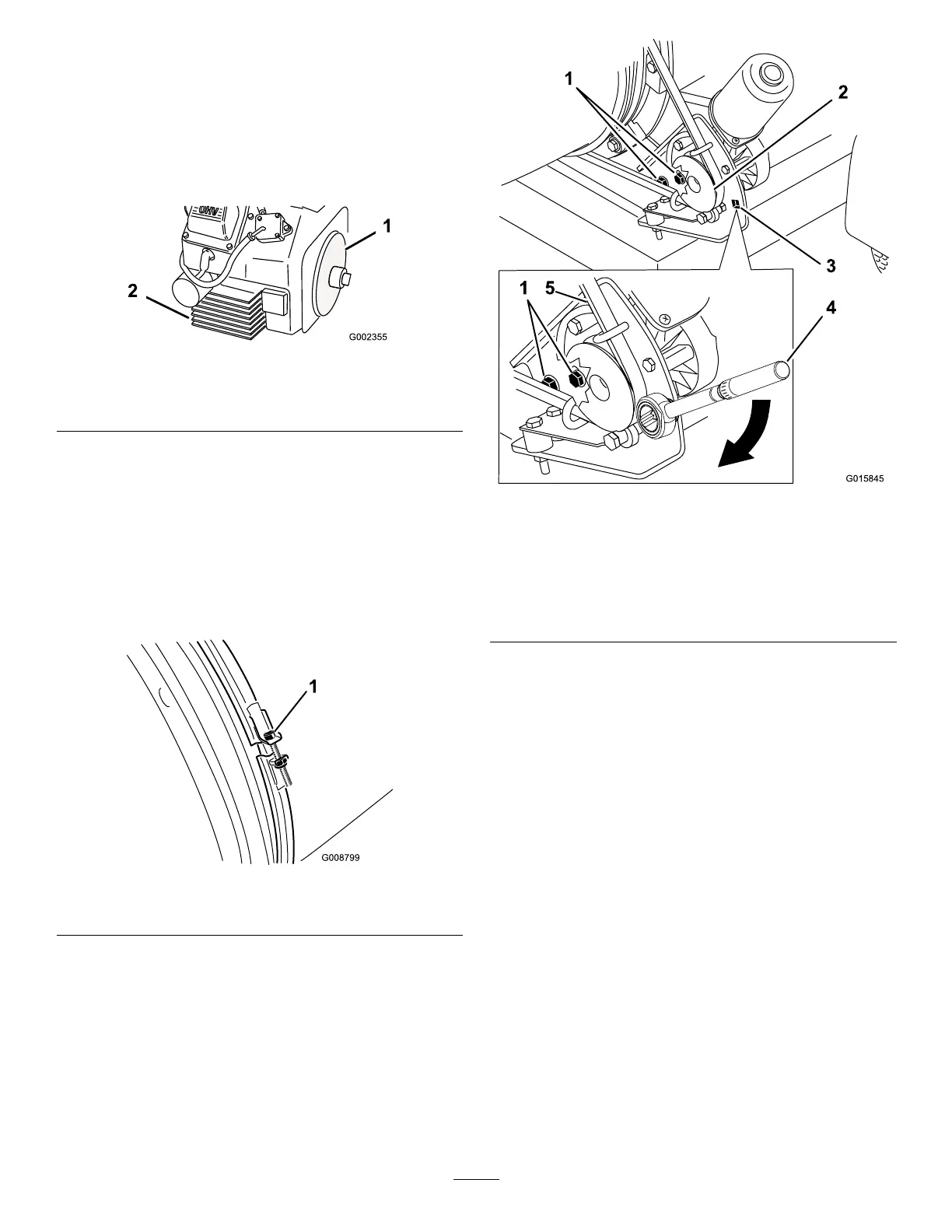

AdjustingtheBelt

ServiceInterval:Aftertherst8hours

Every50hours

Ifthebeltslipswhenchangingthedirectionofthe

nozzle,anadjustmenttothebeltisrequired.

1.Loosentheboltssecuringthepulleymounting

brackettotheblowerframe(Figure30).

Figure30

1.Mountingbolts4.Torquewrenchinpulley

mountingbracket[200

to230in-lb(22.6to26.0

N-m)]

2.Pulley5.Belt

3.Holefortorquewrench

2.Positionatorquewrenchintothepulleymounting

bracket(Figure30).

3.Pivotthepulleymountingbracketawayfromthe

nozzleuntilthetorquewrenchreads200to230in-lb

(22.6to26.0N-m)(Figure30).

4.Tightenthemountingbolts.

ElectricalMaintenance

Important:Beforeweldingonthemachine,

disconnectthecontrollerandthenegativecable

fromthebatterytopreventdamagetotheelectrical

system.

Fuse

A15ampin-linefuseisincorporatedintothemachines

wiring(Figure31).

24

Loading...

Loading...