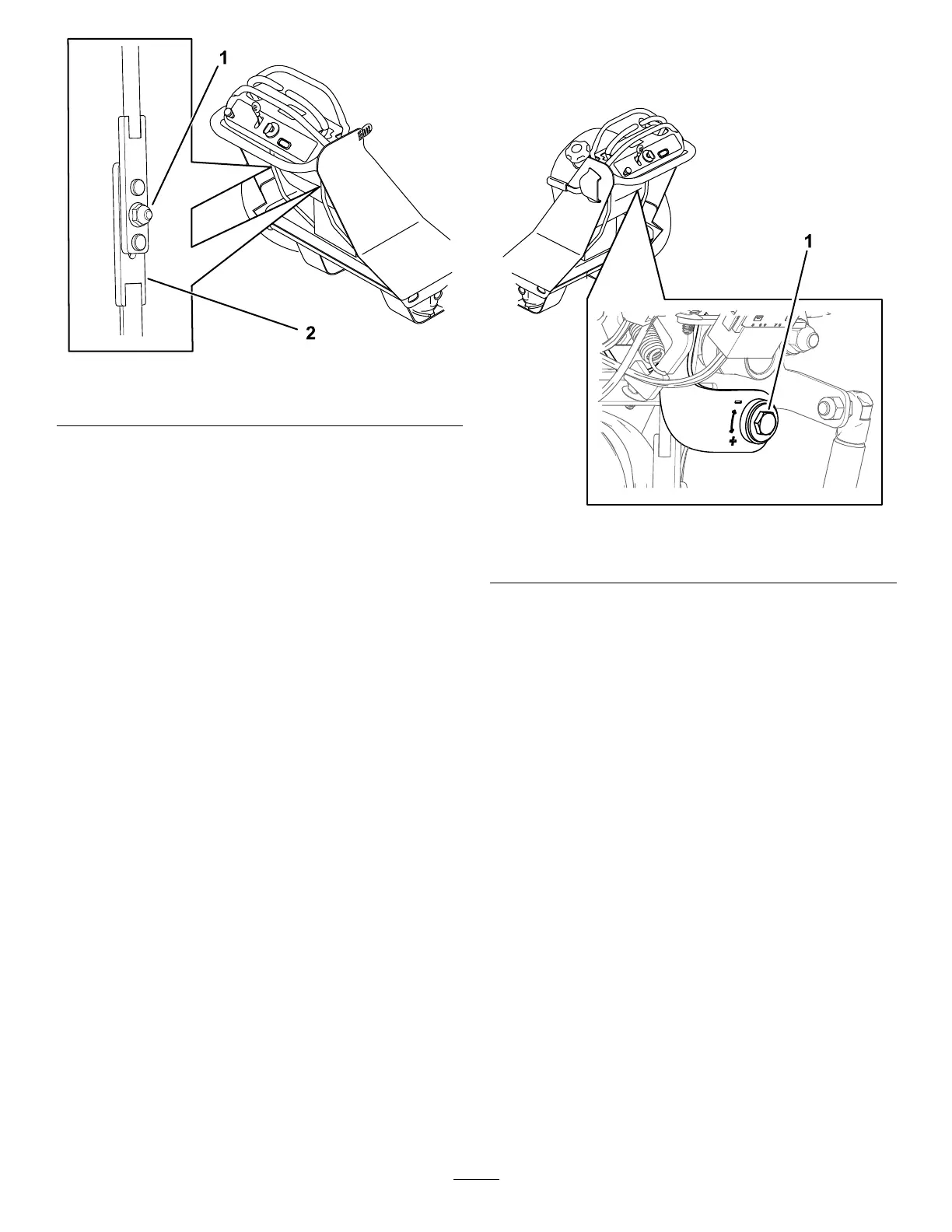

g300245

Figure45

1.Nut2.Lowercontrolrod

5.Startthemachineandmovethethrottlecontrol

totheFASTposition.

6.Tondtheneutralposition,movethelower

controlrodupordownuntilthetirestopsrotating

(Figure45).

7.Tightenthenut(Figure45).

Important:Ensurethattheroddoesnot

move;otherwise,youmayneedtoadjustthe

rodagain.

8.Repeatfortheotherlever.

Note:Youmayneedtoadjustthetrackingafter

adjustingtheneutraltraction;refertoAdjustingthe

Tracking(page35).

AdjustingtheTracking

Ifyoupushbothmotion-controlleversforwardfull

speedacrossaat,levelsurfaceandthemachine

pullsto1side,adjustthetrackingasfollows.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

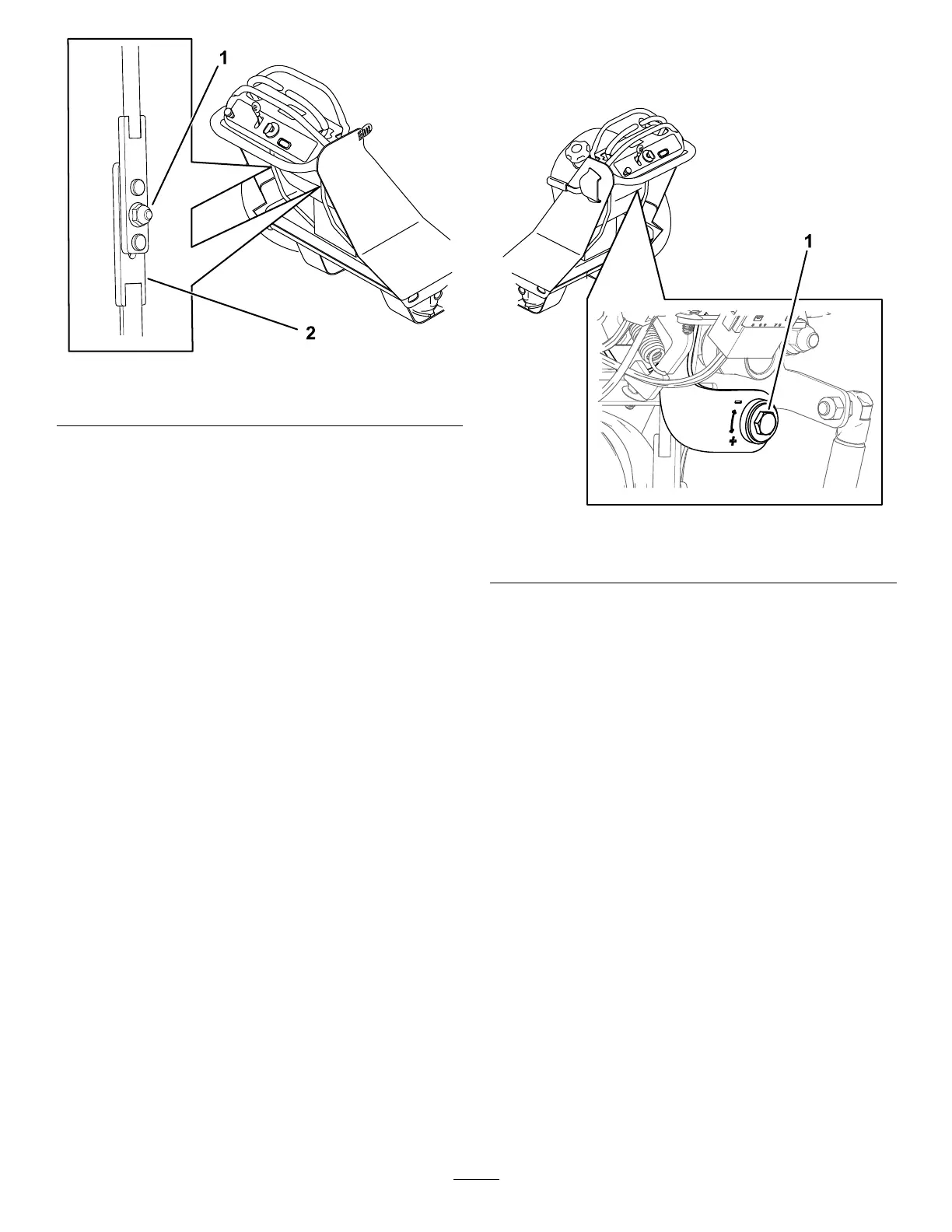

3.RotatetheadjustmentscrewshowninFigure45

toincreaseordecreasethespeedforthatlever.

Note:Rotatethescrewclockwisetodecrease

thespeed;rotateitcounterclockwisetoincrease

thespeed.

Ifthemachinepullstotheleft,decreasethe

speedfortherightleverorincreasethespeed

fortheleftlever.

Ifthemachinepullstotheright,decreasethe

speedfortheleftleverorincreasethespeed

fortherightlever.

g299908

Figure46

1.Adjustmentscrew

4.Startthemachineanddriveforwardacrossa

at,levelsurfacewiththemotion-controllevers

fullyforwardtocheckifthemachinetracks

straight.Repeattheprocedureasneeded.

AdjustingtheCaster-Pivot

Bearing

ServiceInterval:Every500hours/Yearly(whichever

comesrst)

Note:For91cm(36inch)machines,tightenthe

topboltonthecasterwheels.For122cm(48-inch

machines),followtheprocedure.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removethedustcapfromthecasterandtighten

thelocknut(Figure47).

4.Tightenthelocknutuntilthespringwashersare

at,andthenbackoffa1/4turntoproperlyset

thepreloadonthebearings(Figure47).

35

Loading...

Loading...