g027477

Figure66

3.Repeatfortheoppositelter.

4.Installthelterguardsovereachlterthatyou

previouslyremoved(Figure65).

5.Usethe3screwstosecurethelterguards

(Figure65).

AddingHydraulicFluid

1.Verifythattheventplugsareremovedbefore

addingtheuid.

2.Slowlypourthespecieduidthroughthe

expansionreservoiruntiluidcomesoutof1of

thevent-plugholes;refertoHydraulicSystem

Specications(page43).

3.Installtheventplug(Figure65).

4.Torquetheplugto20N∙m(15ft-lb).

5.Continuetoadduidthroughtheexpansion

reservoiruntiluidcomesoutoftheremaining

vent-plugholeonthesecondtransmission.

6.Installtheoppositeventplug.

7.Torquetheplugto20N∙m(15ft-lb).

8.Pivotthetransaxleguardsupandsecureboth

with2boltsand2nuts(Figure64).

9.Installtheguardplate(Figure63).

10.Continuetoadduidthroughtheexpansion

reservoiruntilitreachestheFULLCOLDlineon

theexpansionreservoir.

11.ProceedtoBleedingtheHydraulicSystem

(page45).

Important:Failuretobleedthehydraulic

systemafterchangingthehydrauliclters

anduidcanresultinirreparabledamageto

thetransaxledrivesystem.

BleedingtheHydraulic

System

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Raisetherearofthemachineontojackstands

highenoughtoraisethedrivewheelsoffthe

ground.

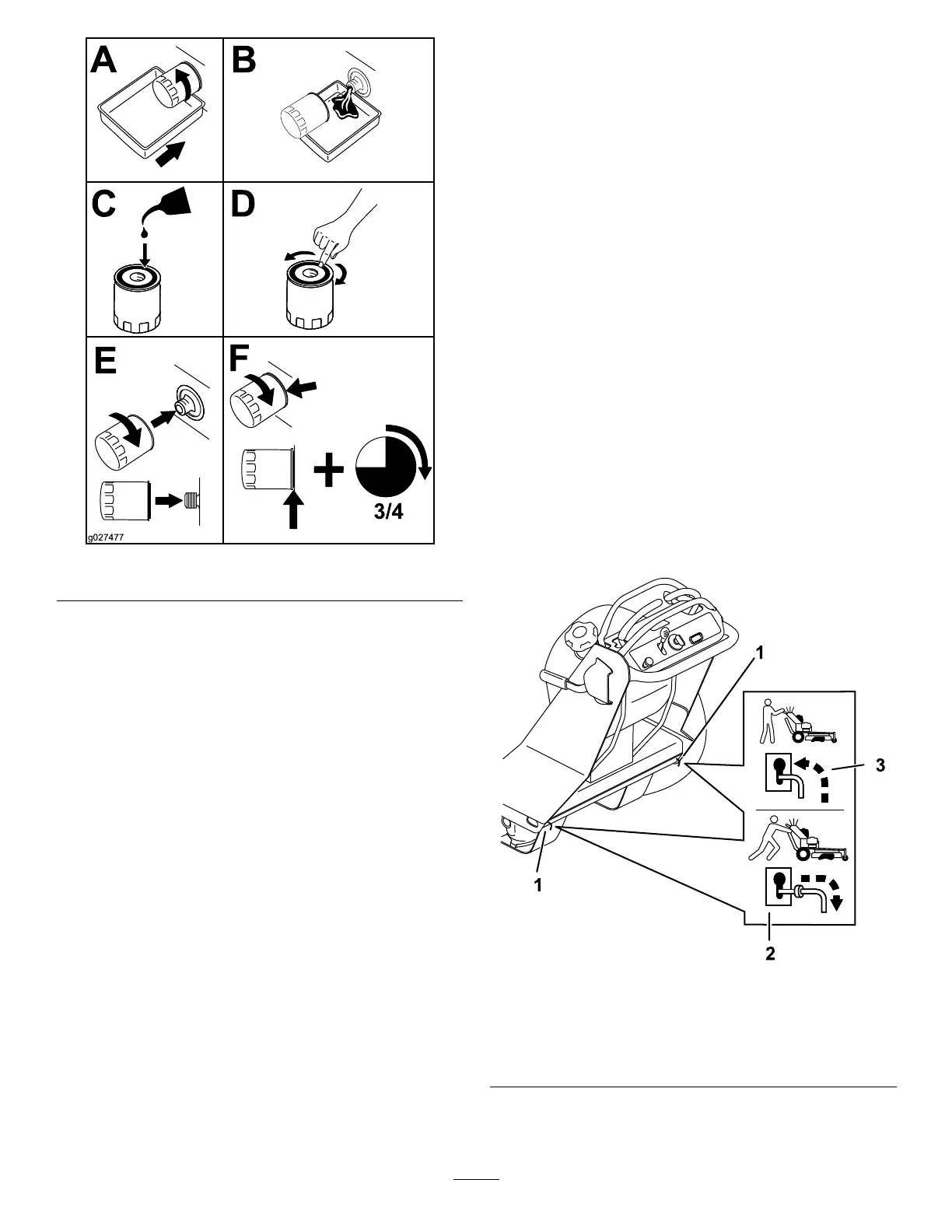

4.Movebothbypassleversrearwardthroughthe

keyholeanddowntolocktheminplace(Figure

67).

g303749

Figure67

1.Bypass-leverlocations

3.Leverpositionforbleeding

thetransmission

2.Leverpositionfor

operatingthemachine

5.Starttheengine.andmovethethrottlecontrol

tohalfthrottle.

45

Loading...

Loading...