HydraulicSystem

Maintenance

HydraulicSystemSafety

•Seekimmediatemedicalattentionifuidisinjected

intoskin.Injecteduidmustbesurgicallyremoved

withinafewhoursbyadoctor.

•Ensurethatallhydraulic-uidhosesandlinesare

ingoodconditionandallhydraulicconnections

andttingsaretightbeforeapplyingpressureto

thehydraulicsystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthigh-pressurehydraulic

uid.

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulicsystem

beforeperforminganyworkonthehydraulic

system.

HydraulicSystem

Specications

HydraulicFluidType:T oro®HYPR-OIL™500

hydraulicuid

HydraulicSystemFluidCapacity:4.7L(159oz)

Important:Usetheuidspecied.Otheruids

coulddamagethesystem.

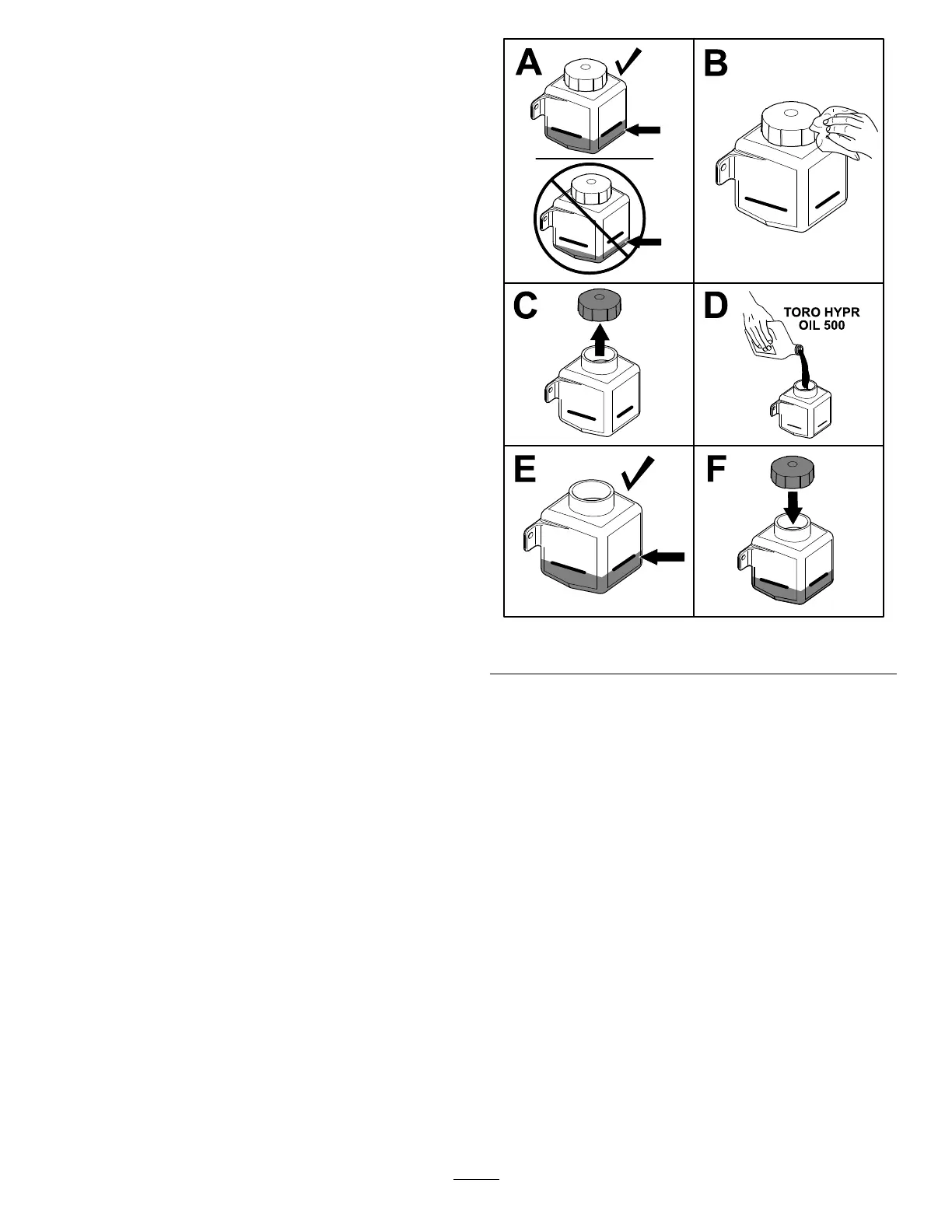

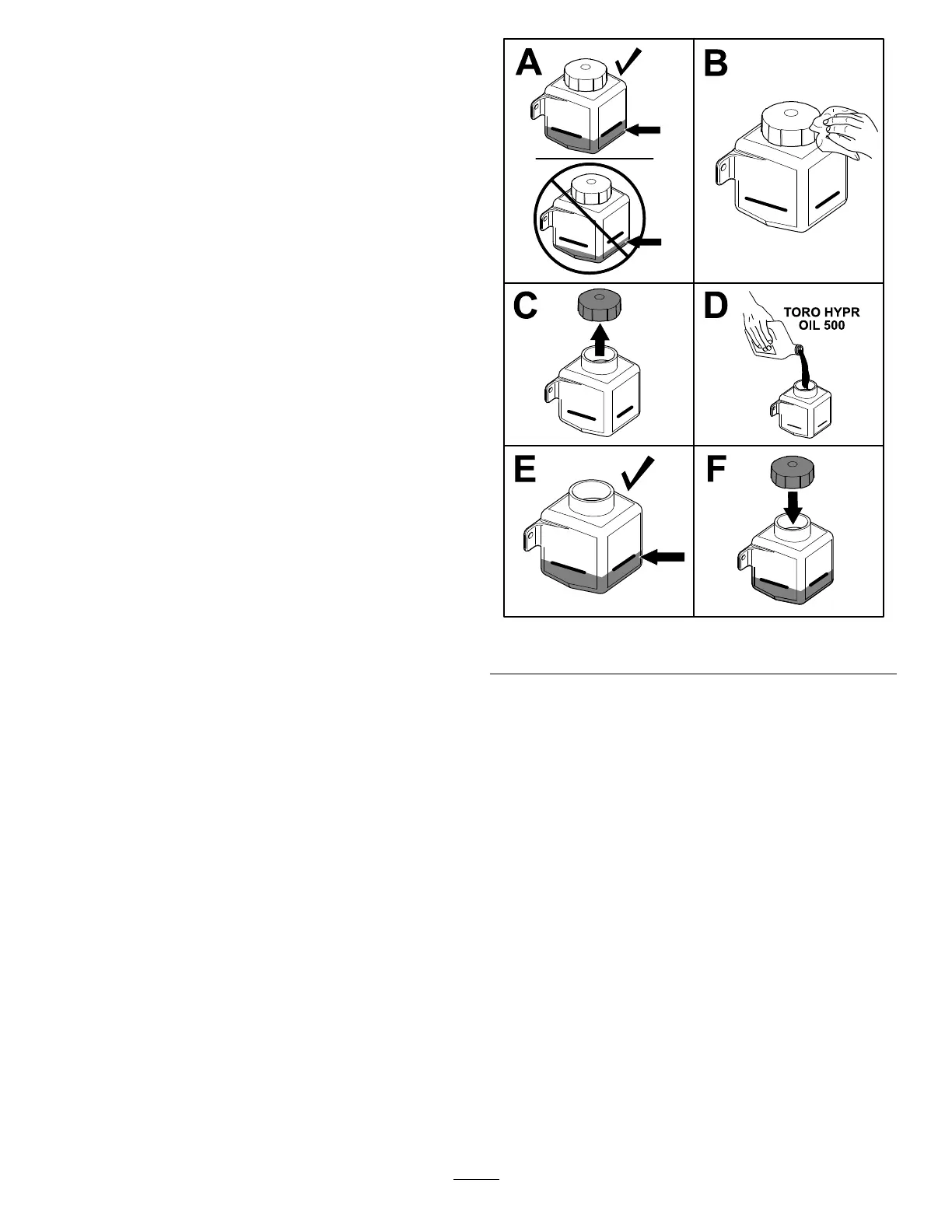

CheckingtheHydraulic

FluidLevel

ServiceInterval:Every50hours

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Allthemachinetocoolcompletely.

4.Checktheuidlevelonthesideofthehydraulic

tank(Figure62).Continuetheprocedureifthe

levelisbelowthecoldlllevel.

5.Cleantheareaaroundthecapofthehydraulic

tank(Figure62).

6.Removethecapfromthellerneckandadd

uidtothereservoiruntilitreachesthecoldll

level(Figure62).

7.Installthecaponthetank(Figure62).

g300398

Figure62

ChangingtheHydraulic

FluidandFilters

ServiceInterval:Aftertherst50hours—Changethe

hydraulic-systemltersanduid.

Every500hours—Aftertheinitial

change—changethehydraulic-system

ltersanduidwhenusingT oro

®

HYPR-OIL

™

500uid.(Changeitmoreoftenunderdirtyor

dustyconditions)

Toreplacethehydraulicuid,theltersneedtobe

removed.Replacebothatthesametime;referto

HydraulicSystemSpecications(page43)foruid

specications.

RemovingtheFiltersandDraining

theFluid

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

43

Loading...

Loading...