3.Measurefromthetipofthebladetotheatsurface

here.

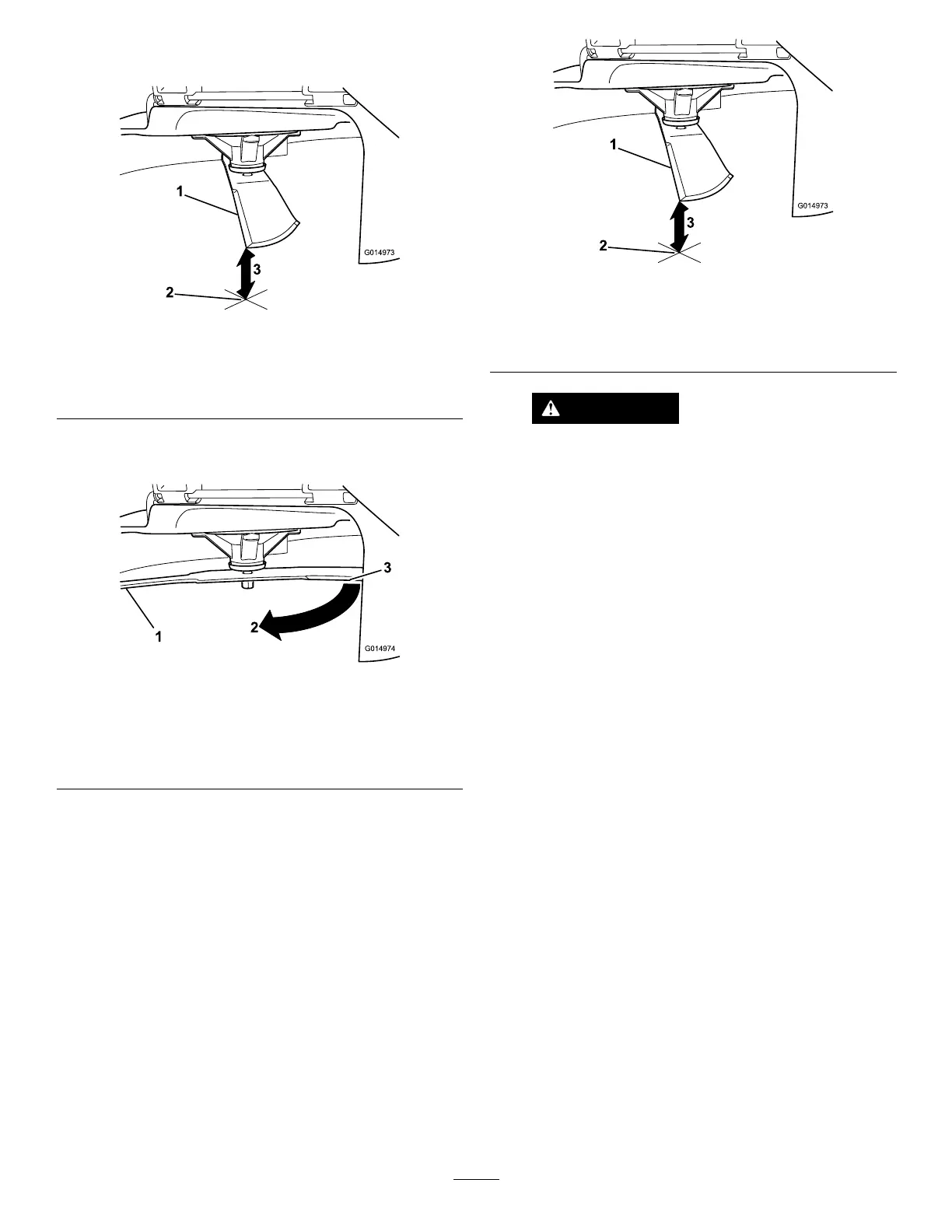

Figure48

1.Blade,inpositionformeasuring

2.Levelsurface

3.Measureddistancebetweenbladeandsurface(A)

4.Rotatethesameblade180degreessothattheopposing

cuttingedgeisnowinthesameposition.

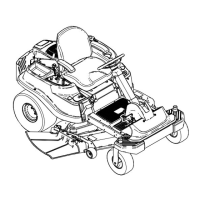

Figure49

1.Blade,sidepreviouslymeasured

2.Measurementpositionusedpreviously

3.Opposingsideofbladebeingmovedintomeasurement

position

5.Measurefromthetipofthebladetotheatsurface

here.Thevarianceshouldbenomorethan1/8inch

(3mm).

Figure50

1.Opposingbladeedge,inpositionformeasuring

2.Levelsurface

3.Secondmeasureddistancebetweenbladeandsurface(B)

WARNING

Abladethatisbentordamagedcouldbreak

apartandcouldseriouslyinjureorkillyouor

bystanders.

•Alwaysreplacebentordamagedblade

withanewblade.

•Neverleorcreatesharpnotchesinthe

edgesorsurfacesofblade.

A.IfthedifferencebetweenAandBisgreater

than1/8inch(3mm)replacethebladewitha

newblade.RefertoRemovingtheBladesand

InstallingtheBlades.

Note:Ifabentbladeisreplacedwithanewone

andthedimensionobtainedcontinuestoexceed

1/8inch(3mm),thebladespindlecouldbebent.

ContactanAuthorizedToroDealerforservice.

B.Ifthevarianceiswithinconstraints,movetothe

nextblade..

Repeatthisprocedureoneachblade.

RemovingtheBlades

Thebladesmustbereplacedifasolidobjectishit,ifthe

bladeisoutofbalance,orthebladeisbent.Toensure

optimumperformanceandcontinuedsafetyconformance

ofthemachine,usegenuineTororeplacementblades.

Replacementbladesmadebyothermanufacturersmayresult

innon-conformancewithsafetystandards.

Holdthebladeendusingaragorthickly-paddedglove.

Removethebladebolt,curvedwasher,andbladefromthe

spindleshaft(Figure51).

40

Loading...

Loading...