RemovingtheHydraulicFilters

Important:Whenthehydrauliclterisremoved,allof

thehydraulicuidineachtransaxlewilldrainout.Usea

containerthatholds4.495L(152oz)orlarger.

1.Shutofftheengine,waitforallmovingpartstostop,

allowtheenginetocool,removethekey,andengage

theparkingbrake.

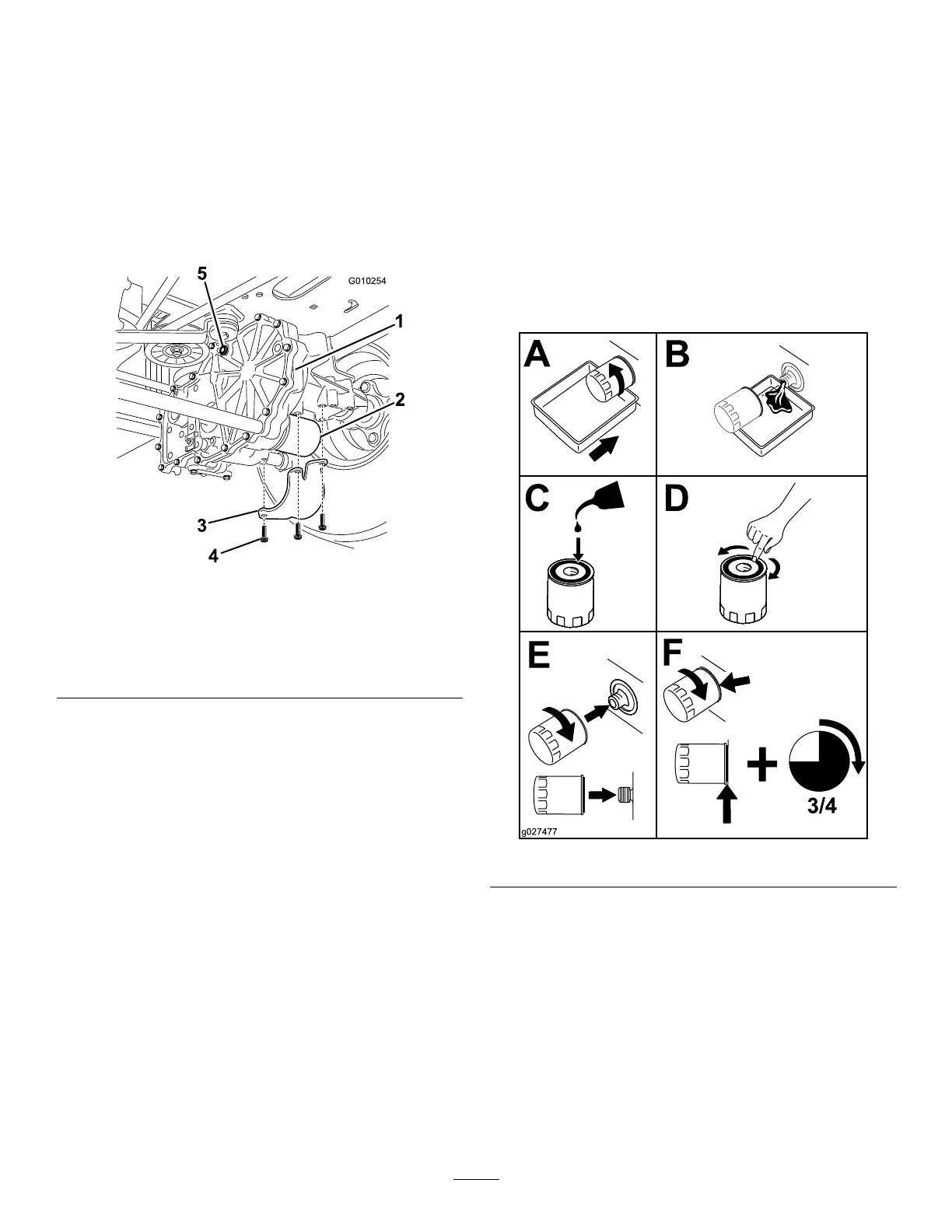

2.Locatethelterandguardsoneachtransaxledrive

systemandremovethe3screwssecuringthelter

guard(Figure58).

Figure58

Rightsideshown

1.Transaxledrive

4.Screws

2.Hydrauliclter

5.Ventplug

3.Filterguard

3.Carefullycleantheareaaroundthelters.

Important:Donotallowdirttoenterthe

hydraulicsystem,asitmaycausedamage.

4.Placeacontainerbelowthelteranddraintheuid.

5.Locateandremovetheventplugoneachtransmission.

6.Unscrewthelterandallowtheuidtodrainfrom

thedrivesystem.

7.Repeatthisprocedureforbothlters.

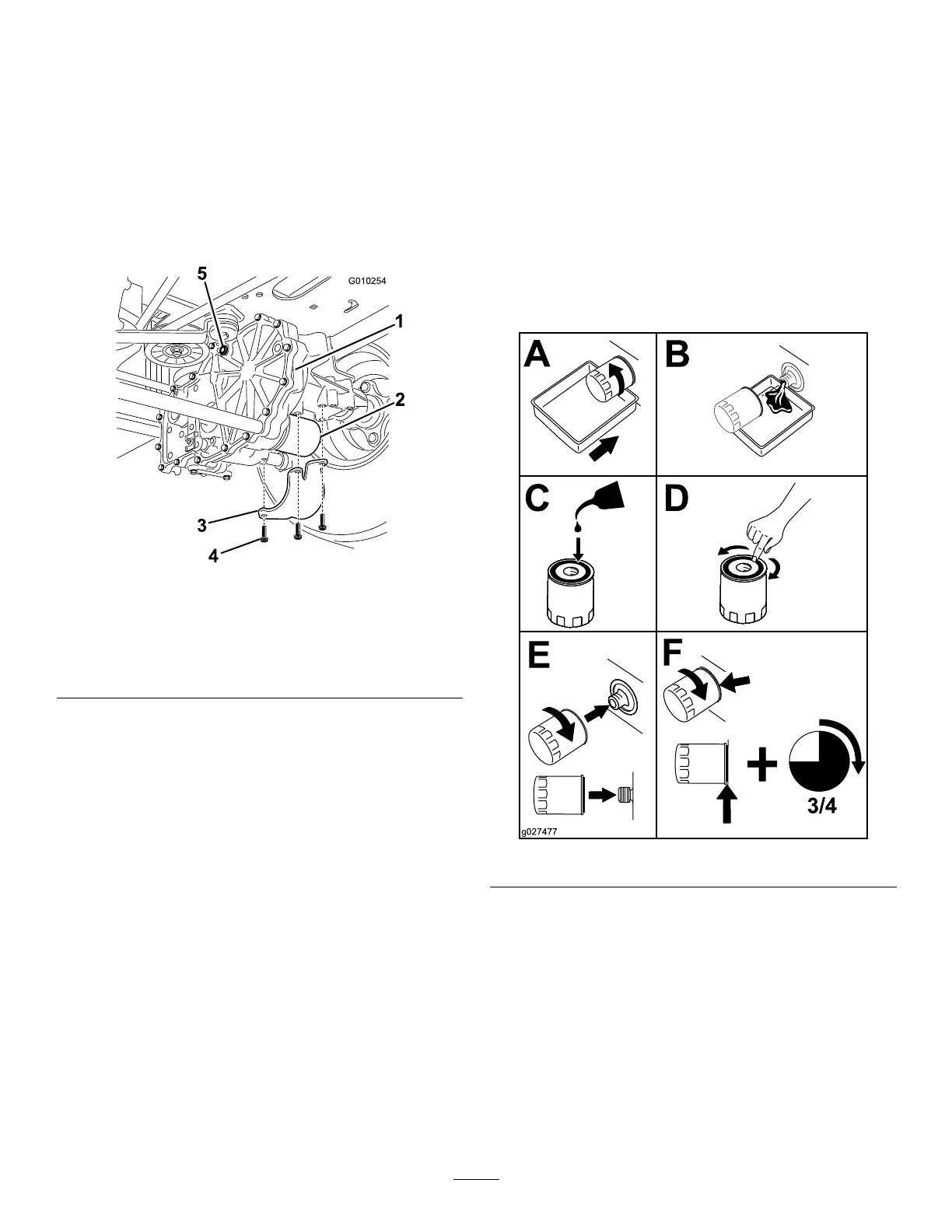

InstallingtheHydraulicFilter

ServiceInterval:Aftertherst50hours

Every400hours

1.Usingthe3screwstoinstallthelterguardsovereach

lterremovedpreviously.

2.Verifythattheventplugsareremovedbeforeadding

theuid.

3.Slowlypourthespecieduidthroughtheexpansion

reservoiruntiluidcomesoutofavent-plughole.

4.Installtheventplugandtorqueitto20N•m(180in-lb).

5.Continuetoadduidthroughtheexpansionreservoir

untiluidcomesoutoftheremainingvent-plughole

onthesecondtransmission.

6.Installthesecondventplugandtorqueitto20N•m

(180in-lb).

7.Continuetoadduidthroughtheexpansionreservoir

untilitreachestheFullColdlineontheexpansion

reservoir.

Important:Failuretoperformthe

Bleeding

the Hy draulic System

procedureafterchanging

hydraulicltersandoilcanresultinirreparable

damagetothetransaxledrivesystem.

Figure59

42

Loading...

Loading...