BeltMaintenance

InspectingtheBelts

ServiceInterval:Every40hours

Replacethebeltifitisworn.Thesignsofawornbelt

includesquealingwhilethebeltisrotating;theblades

slippingwhilecuttinggrass;andfrayededges,burn

marks,andcracksonthebelt.

1.Parkthemachineonalevelsurface,movethe

speed-controllevertotheNEUTRALposition,

disengagethePTO,andengagetheparking

brake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.TiltthehopperupandcheckthepumpandPTO

drivebeltsforwear,cracking,orcontamination.

Note:Thebeltsarespringtensionedandno

adjustmentisnecessaryunlessthebeltsare

replaced.

ReplacingthePTOBelts

1.Parkthemachineonalevelsurface,movethe

speed-controllevertotheNEUTRALposition,

disengagethePTO,andengagetheparking

brake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Withtheengineoff,engagethePTOlever,then

removethehairpincotterandclevispinatthe

bottomofthePTO-brakeband.

4.Rotatethebrakebandupwardandoutofthe

wayofthebeltskeepingclearofthebeltdrive.

5.DisengagethePTOlever.

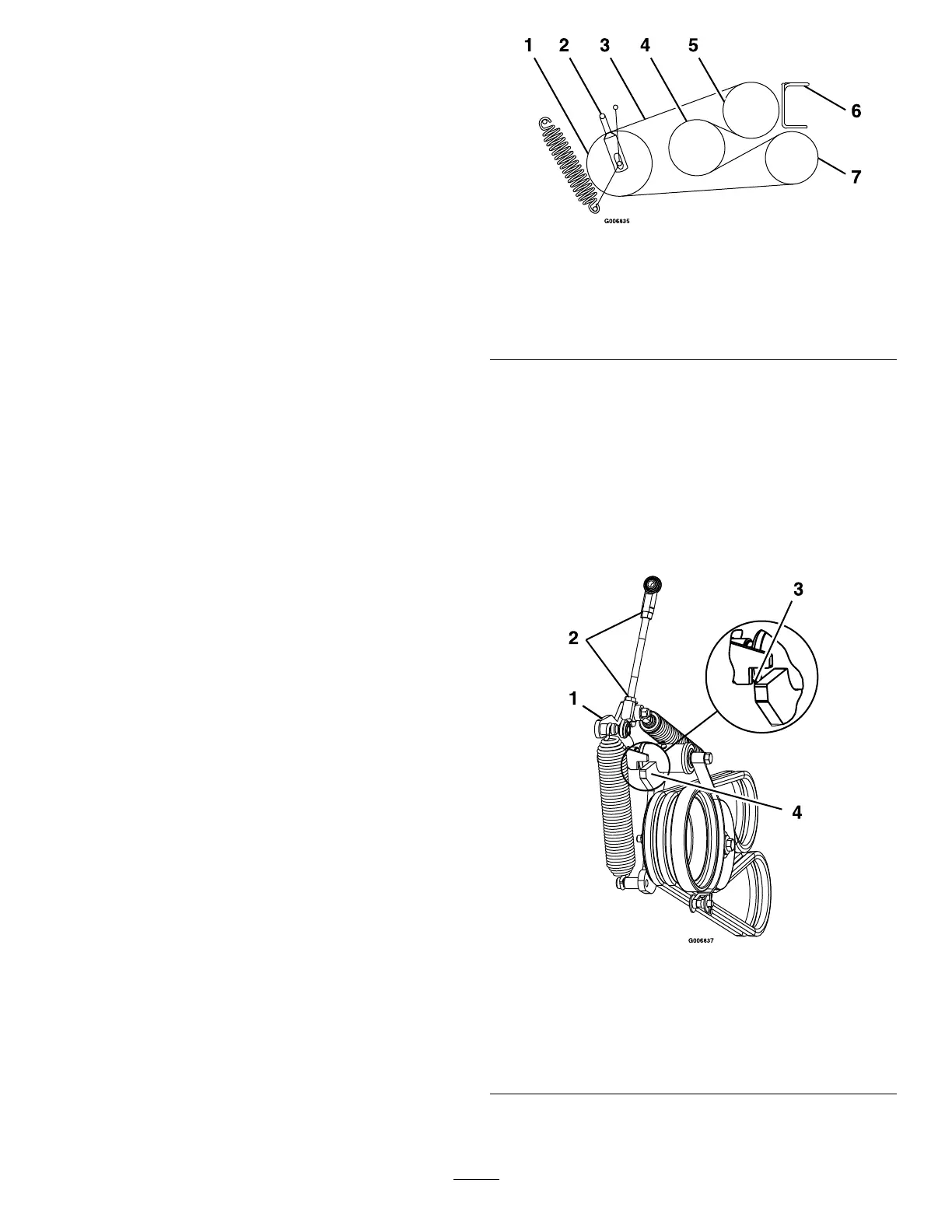

6.LoosenbeltguidesAandB(Figure60).

7.Removethebelts.

8.Routethenewbeltsontothepulleysasshown

inFigure60.

g006836

Figure60

1.Idler5.Engine

2.BeltguideB6.BeltguideA

3.PTObelt

7.Blower

4.Jackshaft

9.EngagethePTOlever.

10.Rotatethebrakebanddownintotheoriginal

position.

11.Installtheclevispinandhairpincottertosecure

thebrakeband.

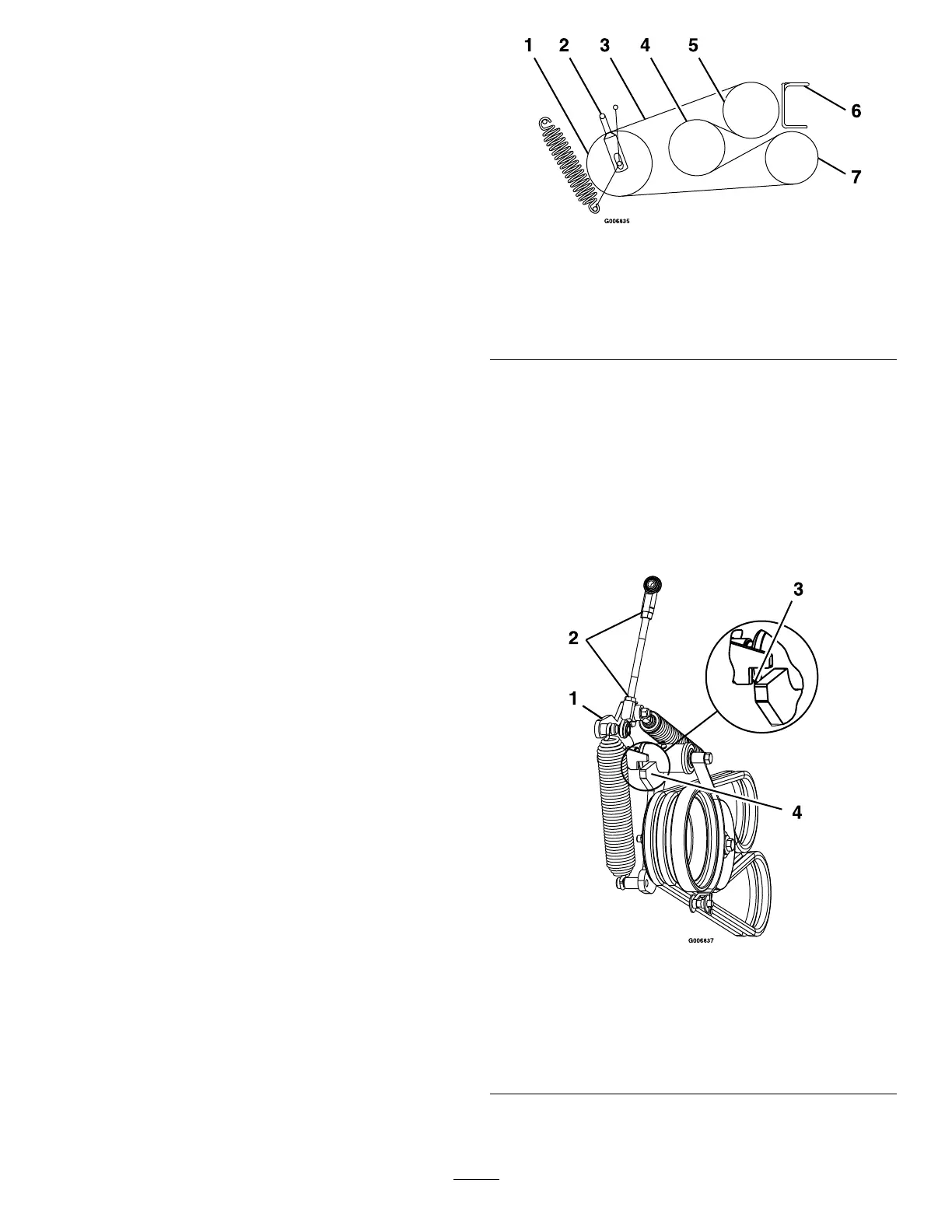

12.Loosenthejamnutsandadjustthelinkageuntil

thetopoftheidlerarmisalignedwiththebottom

ofthenotchonthetensionarmasshownin

Figure61.

g006837

Figure61

1.Tensionarm

2.Loosenthejamnuts.

3.WhenPTOisengaged,aligntopofidlerarmwithbottomof

notchontensionarm,asshown.

4.Idlerarm

13.TightenthejamnutsanddisengagethePTO

lever.

49

Loading...

Loading...