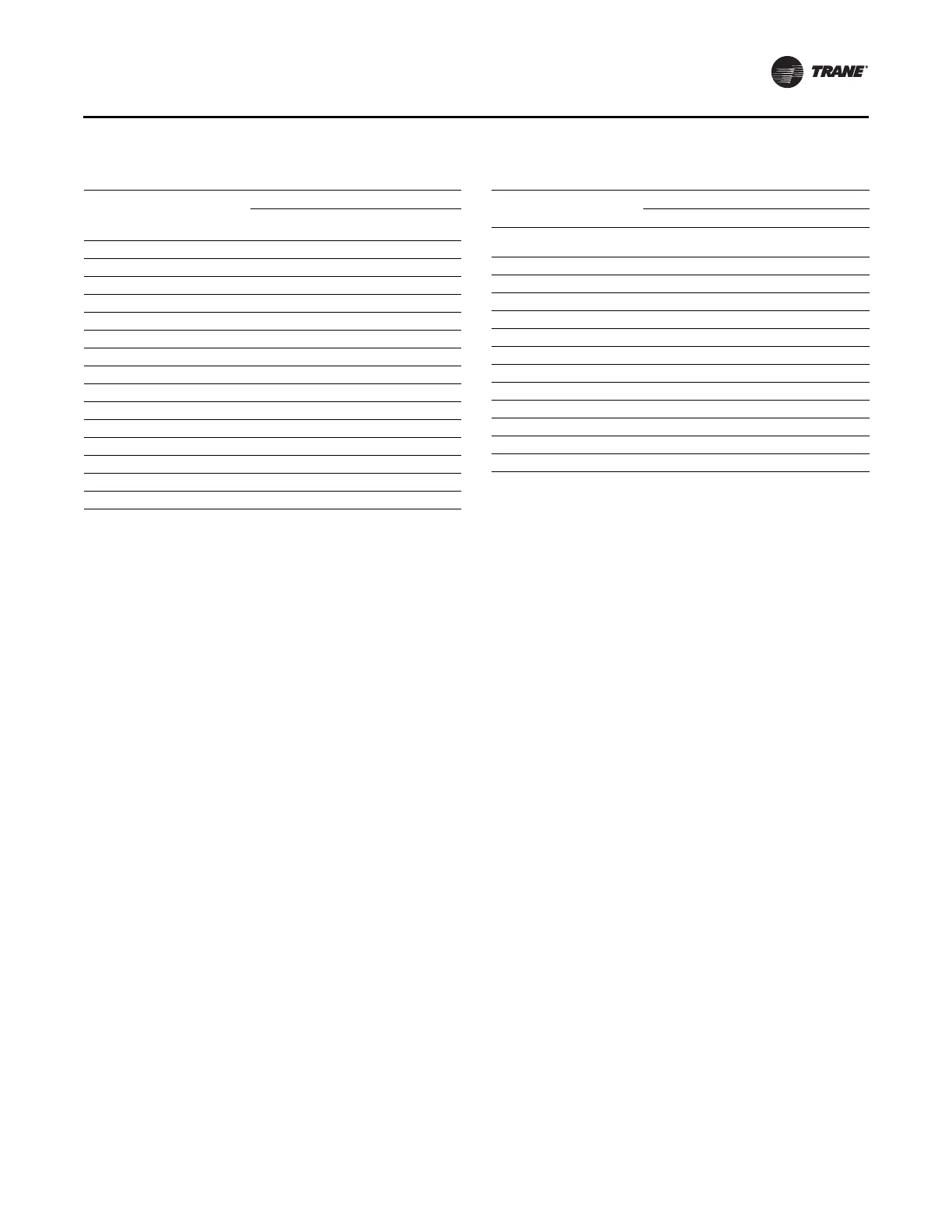

Table 6. Pressure drops for primary loop components at

minimum flow (ft of water)

Frame 3 Frame 4

405 A and 600 A

900 A and

1200 A

Air-Cooled Heat Exchanger 3 12

Water-Cooled Heat Exchanger 3 12

Drive 23 23

3/4-in. Tube (each foot) 0.17 0.68

1-in. Tube (each foot) 0.043 0.17

3/4-in. Straight Coupling 0.55 2.2

3/4-in. 45° Coupling 0.62 2.4

3/4-in. 90° Coupling 0.62 2.4

3/4-in. 90° Elbow Adapter 0.32 1.3

3/4-in. 45° Elbow Adapter 0.17 0.68

1-in. Straight Coupling 0.16 0.62

1-in. 45° Coupling 0.18 0.71

1-in. 90° Coupling 0.18 0.71

1-in. 90° Elbow Adapter 0.11 0.43

1-in. 45° Elbow Adapter 0.058 0.23

Plumbing

AFDK-SVU01C-EN 27

The flow in the secondary loop is established by the

pressure drop across the chiller evaporator. To calculate

the maximum piping distance for the secondary loop,

complete the following steps:

1. Measure the available pressure between the inlet and

the o

utlet of the chiller eva

porator. This value will vary

from chiller to chiller due to equipment and system

differences.

2. Use Table 7 to locate the pressure

drop

at minimum

flow due to the heat exchanger and fittings used.

Subtract these values from the available pressure and

save this result.

3. Use Table 7 to locate the pressure

drop

at minimum

flow due to each foot of tubing that is planned to be

used in the secondary loop. Divide the value obtained

in Step 2 by this number. The result of this calculation

is the maximum le

ngth of tubing that may be used in

the secondary loop.

Note: T

he maximum length of tube includes both the

suppl

y tube and return tube. The distance

between the chiller and heat exchanger should

be half the maximum tube length or less.

4. Verify that the tube length needed for installation does

no

t exceed

the maximum tube length obtained by this

calculation.

Note: I

f the calculated distance using 3/4-in. tubing

does not provide an a

dequate distance for

installation, recalculate the maximum distance

using 1-in. tubing and fittings.

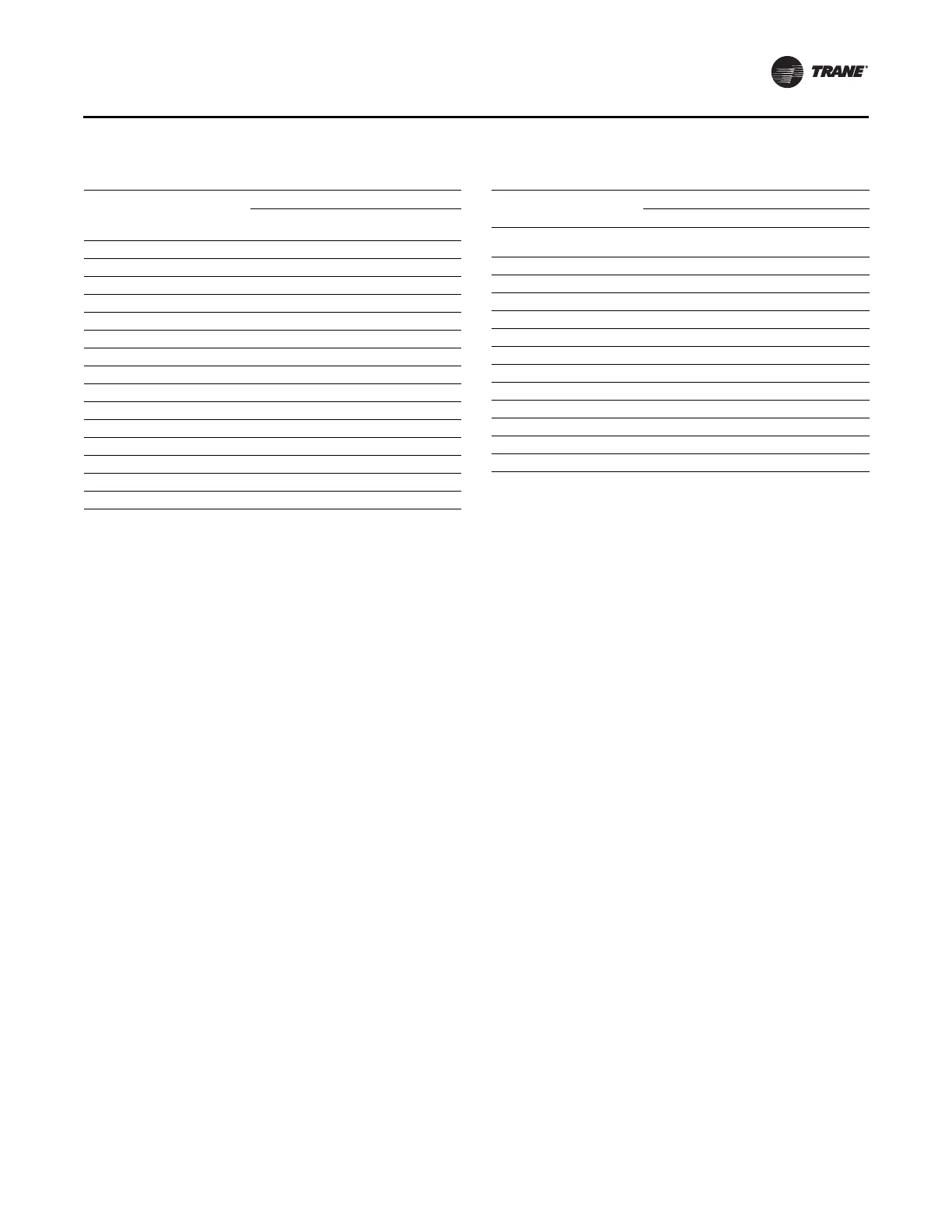

Table 7. Pressure drops for secondary loop components

at mi

nimum flow (ft of water)

Frame 3 Frame 4

405 A 600 A 900 A 1200 A

Water-Cooled Heat

Exchanger

1 1.8 3 6.5

3/4 in. Tube (each foot) 0.066 0.14 0.23 0.47

1 in. Tube (each foot) 0.017 0.035 0.058 0.12

3/4 in. Straight Coupling 0.21 0.44 0.73 1.5

3/4 in. 45° Coupling 0.24 0.49 0.82 1.7

3/4 in. 90° Coupling 0.24 0.49 0.82 1.7

3/4 in. 90° Elbow Adapter 0.12 0.26 0.43 0.89

3/4 in. 45° Elbow Adapter 0.066 0.14 0.23 0.47

1 in. Straight Coupling 0.061 0.13 0.21 0.44

1 in. 45° Coupling 0.069 0.14 0.24 0.5

1 in. 90° Coupling 0.069 0.14 0.24 0.5

1 in. 90° Elbow Adapter 0.042 0.086 0.14 0.3

1 in. 45° Elbow Adapter 0.022 0.046 0.077 0.16

Loading...

Loading...