RT-SVX072A-EN

115

OCC/UNOCC Relay (Unoccupied for VAV units)

All Compressors for each circuit (On)

Condenser Fans for each circuit (On)

WWAARRNNIINNGG

RRoottaattiinngg CCoommppoonneennttss!!

FFaaiilluurree ttoo ddiissccoonnnneecctt ppoowweerr bbeeffoorree sseerrvviicciinngg ccoouulldd

rreessuulltt iinn rroottaattiinngg ccoommppoonneennttss ccuuttttiinngg aanndd ssllaasshhiinngg

tteecchhnniicciiaann wwhhiicchh ccoouulldd rreessuulltt iinn ddeeaatthh oorr sseerriioouuss

iinnjjuurryy..

DDiissccoonnnneecctt aallll eelleeccttrriicc ppoowweerr,, iinncclluuddiinngg rreemmoottee

ddiissccoonnnneeccttss bbeeffoorree sseerrvviicciinngg.. FFoollllooww pprrooppeerr

lloocckkoouutt//ttaaggoouutt pprroocceedduurreess ttoo eennssuurree tthhee ppoowweerr

ccaann nnoott bbee iinnaaddvveerrtteennttllyy eenneerrggiizzeedd..

4. Press the Auto Button key to start the test.

Remember that the delay designated in step 4 must

elapse before the system will begin to operate.

5. After all of the compressors and condenser fans for

the number 1 circuit have been operating for

approximately 30 minutes, observe the operating

pressures. Use the appropriate pressure curve

found in “Pressure Curves,” p. 102 to determine the

proper operating pressures. For superheat and

subcooling guidelines, refer to “Electronic

Expansion Valves,” p. 118.

IImmppoorrttaanntt:: Do Not release refrigerant to the

atmosphere! If adding or removing

refrigerant is required, the service

technician must comply with all

Federal, State and local laws.

6. Verify that the oil level in each compressor is

correct. The oil level may be down to the bottom of

the sightglass but should never be above the

sightglass.

7. Press the STOP key and clear all Manual Overrides

in the unit control panel to stop the system

operation.

8. Repeat steps 1 through 8 for the number 2

refrigeration circuit.

Compressor Crankcase Heaters

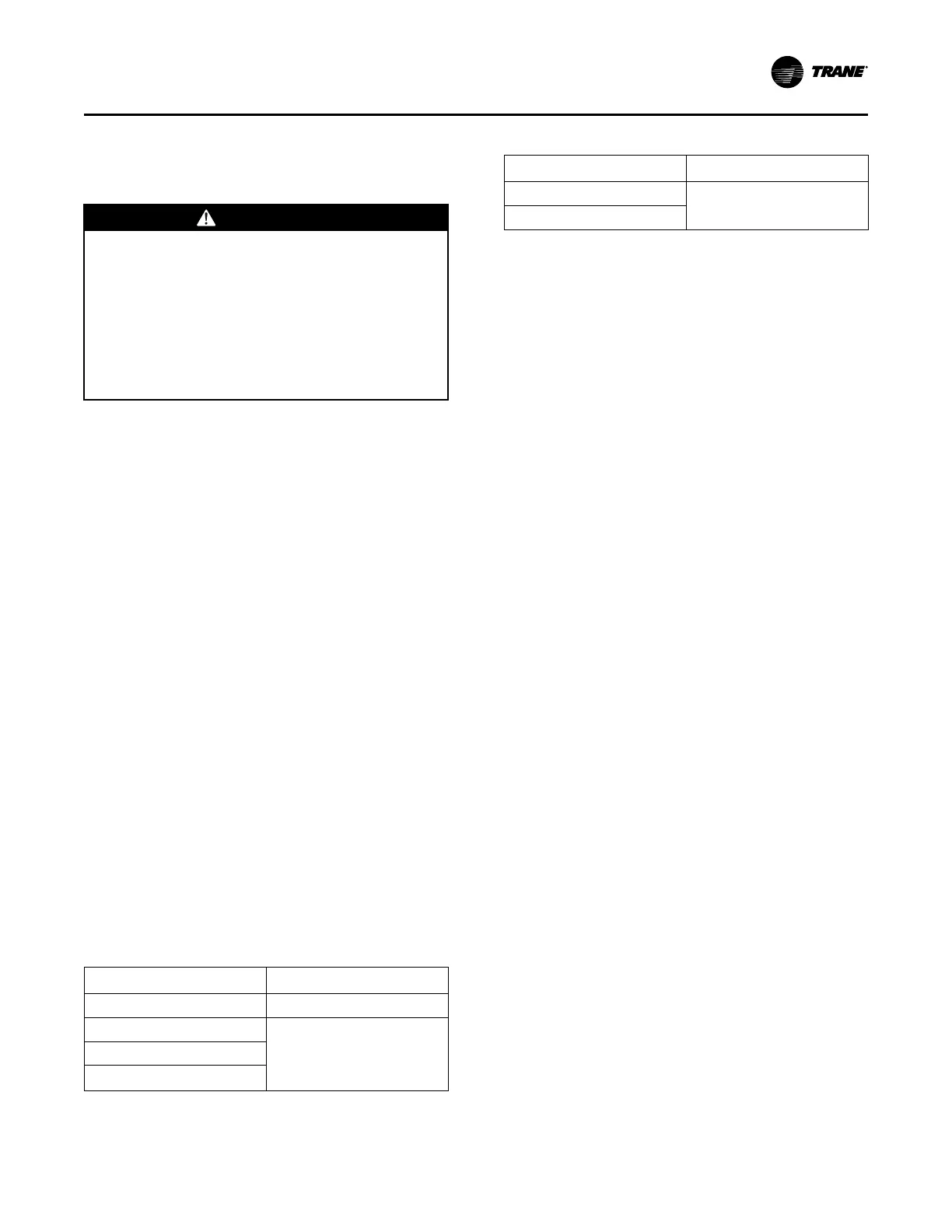

Please see the table below for the crankcase heater

sizes used for each compressor type.

Table 50. Crankcase heater sizes

Compressor Name

Crankcase Heater Watts

ZPS* 70

ZP*

90

CSHD*

VZH088*, VZH117*

Table 50. Crankcase heater sizes (continued)

Compressor Name

Crankcase Heater Watts

VZH170*

160

CSHN*

Compressor Operational Sounds

At Low Ambient Start-Up

When the compressor starts up under low ambient

conditions, the initial flow rate of the compressor is low

due to the low condensing pressure. This causes a low

differential across the expansion valve that limits its

capacity. Under these conditions, it is not unusual to

hear the compressor rattle until the suction pressure

climbs and the flow rate increases.

Variable Speed Compressors

At all operating speeds, eFlex™ permanent magnet

variable speed compressors sound different than fixed

speed scrolls. At low speed, variable speed

compressors can sputter. At high speed, variable speed

compressor buzz. These are normal operating sounds.

To ensure a quiet installation, eFlex variable speed

compressors are installed in a sound enclosure. Make

sure and keep the sound enclosure installed at all times

other than servicing.

IImmppoorrttaanntt:: Variable speed scroll compressors sound

different than single speed scroll

compressors. Sound changes with speed

and condition.

Electronic Compressor Protection

Module (CPM)

The CSHN*** compressors come equipped with a

compressor protection device (CPM) capable of

detecting phase reversal, phase loss, and motor

overheating. When a fault is identified, the output relay

will open. Depending on the fault, the CPM may either

auto-reset or it may lock-out. The CPM can be manually

reset by cycling control power.

NNoottee:: If the compressor has tripped due to an

overheated windings condition, the motor

winding temperature sensor resistance (PTC) will

be 4500 ohms or greater; the resistance must be

less than 2750 ohms before the 5 minute reset

timer becomes enabled.

UUnniitt SSttaarrttuupp

Loading...

Loading...