RT-SVX072A-EN

113

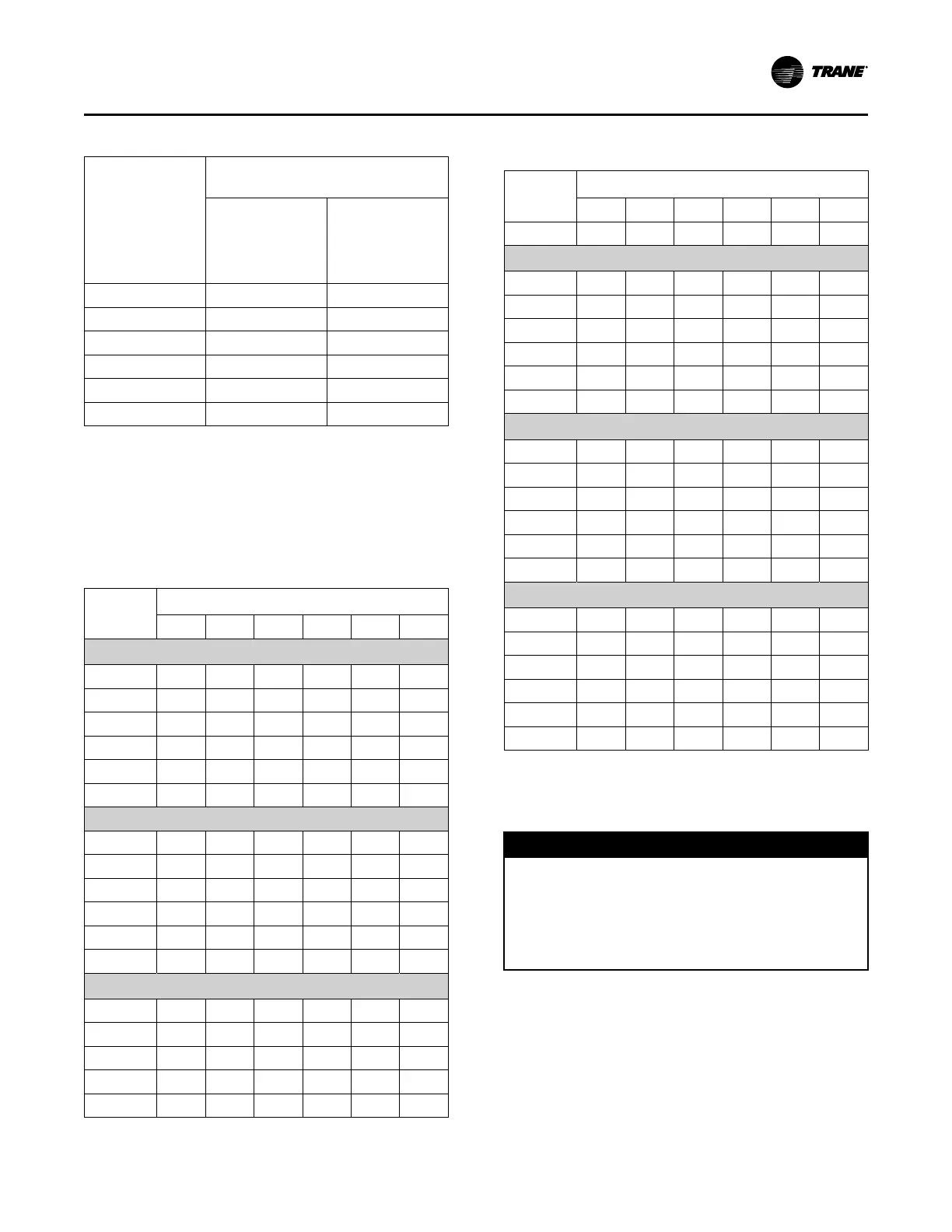

Table 48. O/A Damper travel adjustment

Position of

Connecting Rod

Damper Crank Arm Hole

Configuration

Standard and

Low Leak F/A

Dampers

(Figure 95, p.

112)

Ultra Low Leak

F/A Dampers

(Figure 96, p.

112)

Position #1 2–3 1–6

Position #2 2–4 2–6

Position #3 2–5 3–7

Position #4 2–6 4–8

Position #5 1–8 5–9

Position #6 1–7 5–7

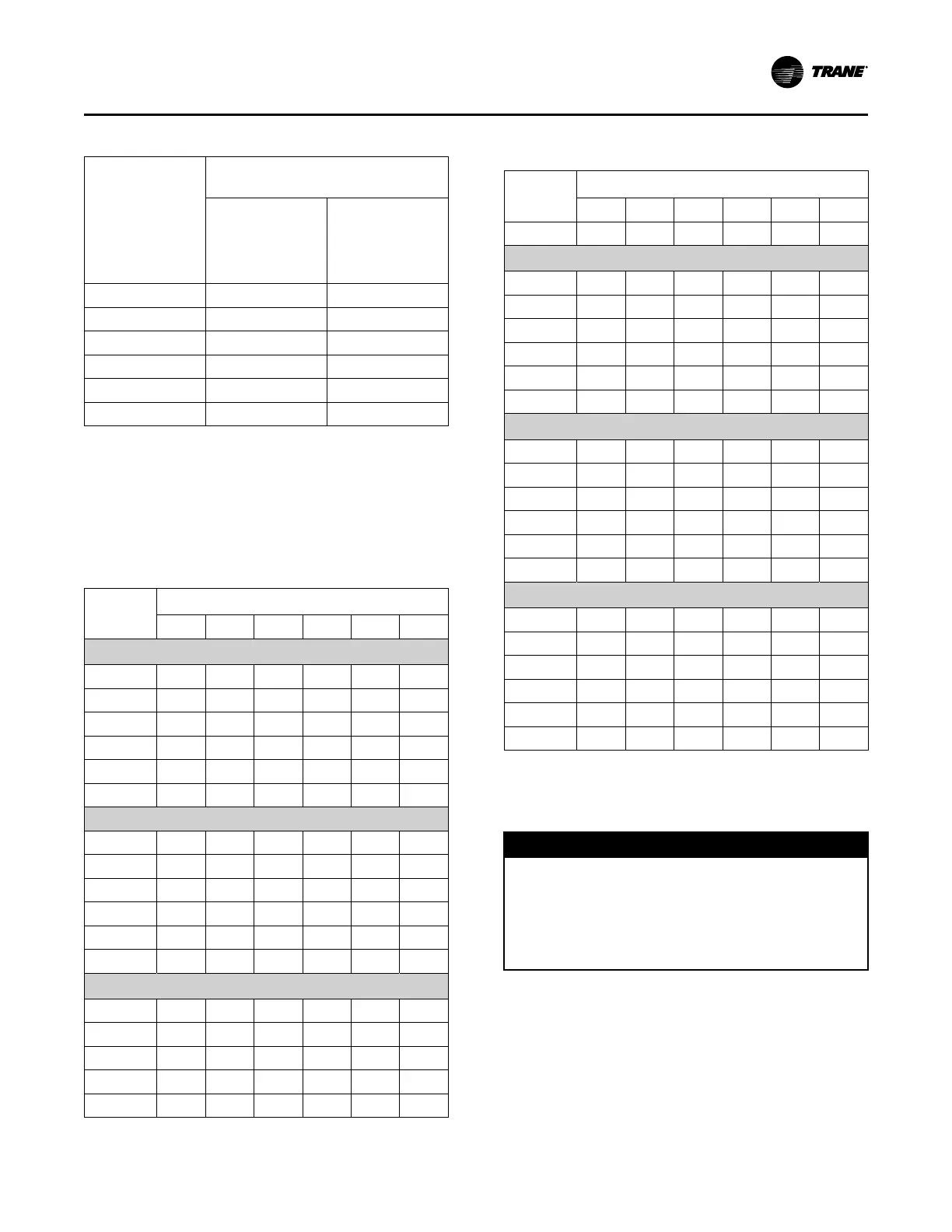

Use Table 49, p. 113 to select the appropriate crank

arm hole configuration based on the following:

• specific unit

• operating CFM

• and return static pressure

Table 49. Outside air damper pressure drop (inches

w.c.) — air-cooled

CFM

Damper Position

#1 #2 #3 #4 #5 #6

20, 25 Ton

4000 0.03 0.04 0.06 0.13 0.16 0.33

6000 0.03 0.04 0.10 0.20 0.30 0.90

8000 0.19 0.21 0.32 0.52 0.75 1.75

9000 0.30 0.35 0.48 0.76 1.08 2.40

10000 0.45 0.51 0.70 1.05 1.57 -

11000 0.62 0.71 0.95 1.42 2.15 -

30

6000 0.03 0.04 0.07 0.15 0.20 0.43

8000 0.03 0.05 0.11 0.21 0.30 0.90

10000 0.15 0.19 0.26 0.43 0.62 1.50

11000 0.20 0.25 0.37 0.60 0.85 1.85

12000 0.31 0.36 0.50 0.79 1.10 2.40

13000 0.42 0.48 0.62 0.97 1.42 -

40, 48 Ton

8000 0.03 0.04 0.08 0.16 0.21 0.52

10000 0.03 0.05 0.11 0.21 0.30 0.90

12000 0.10 0.13 0.21 0.38 0.55 1.40

14000 0.20 0.25 0.37 0.60 0.85 1.85

16000 0.41 0.46 0.60 0.94 1.38 -

Table 49. Outside air damper pressure drop (inches

w.c.) — air-cooled (continued)

CFM

Damper Position

#1 #2 #3 #4 #5 #6

18000 0.56 0.65 0.74 1.28 1.92 -

50, 55 Ton

10000 0.03 0.04 0.09 0.18 0.23 0.55

14000 0.09 0.12 0.20 0.35 0.50 1.36

18000 0.31 0.36 0.50 0.79 1.10 -

20000 0.45 0.51 0.70 1.05 1.57 -

22000 0.58 0.66 0.75 1.30 1.95 -

24000 0.75 0.88 1.10 1.75 2.50 -

(60, 70, 75 Ton) Units

14000 0.03 0.04 0.12 0.25 0.35 1.05

18000 0.19 0.21 0.32 0.52 0.75 1.75

22000 0.45 0.51 0.70 1.05 1.57 -

26000 0.70 0.80 1.02 1.58 2.30 -

28000 0.88 1.03 1.30 2.20 - -

30000 1.05 1.22 1.55 2.65 - -

(90 to 130 Ton) Units

27000 0.31 0.36 0.50 0.79 1.10 2.40

32000 0.55 0.64 0.72 1.25 1.88 -

36000 0.75 0.88 1.10 1.75 2.50 -

40000 1.00 1.18 1.50 2.50 - -

43000 1.20 1.42 1.92 - - -

46000 1.40 1.58 2.29 - - -

Compressor Startup (All

Systems)

NNOOTTIICCEE

CCoommpprreessssoorr FFaaiilluurree!!

FFaaiilluurree ttoo ffoollllooww iinnssttrruuccttiioonn bbeellooww ccoouulldd rreessuulltt iinn

ccoommpprreessssoorr ffaaiilluurree..

UUnniitt mmuusstt bbee ppoowweerreedd aanndd ccrraannkkccaassee hheeaatteerrss

eenneerrggiizzeedd aatt lleeaasstt 88 hhoouurrss BBEEFFOORREE ccoommpprreessssoorrss

aarree ssttaarrtteedd..

1. Ensure that the “System” selection switch at the

remote panel is in the “Off” position.

2. Before closing the disconnect switch, ensure that

the compressor discharge service valve for each

circuit is back seated.

UUnniitt SSttaarrttuupp

Loading...

Loading...