38

S9V2-VS-SVX001-1B-EN

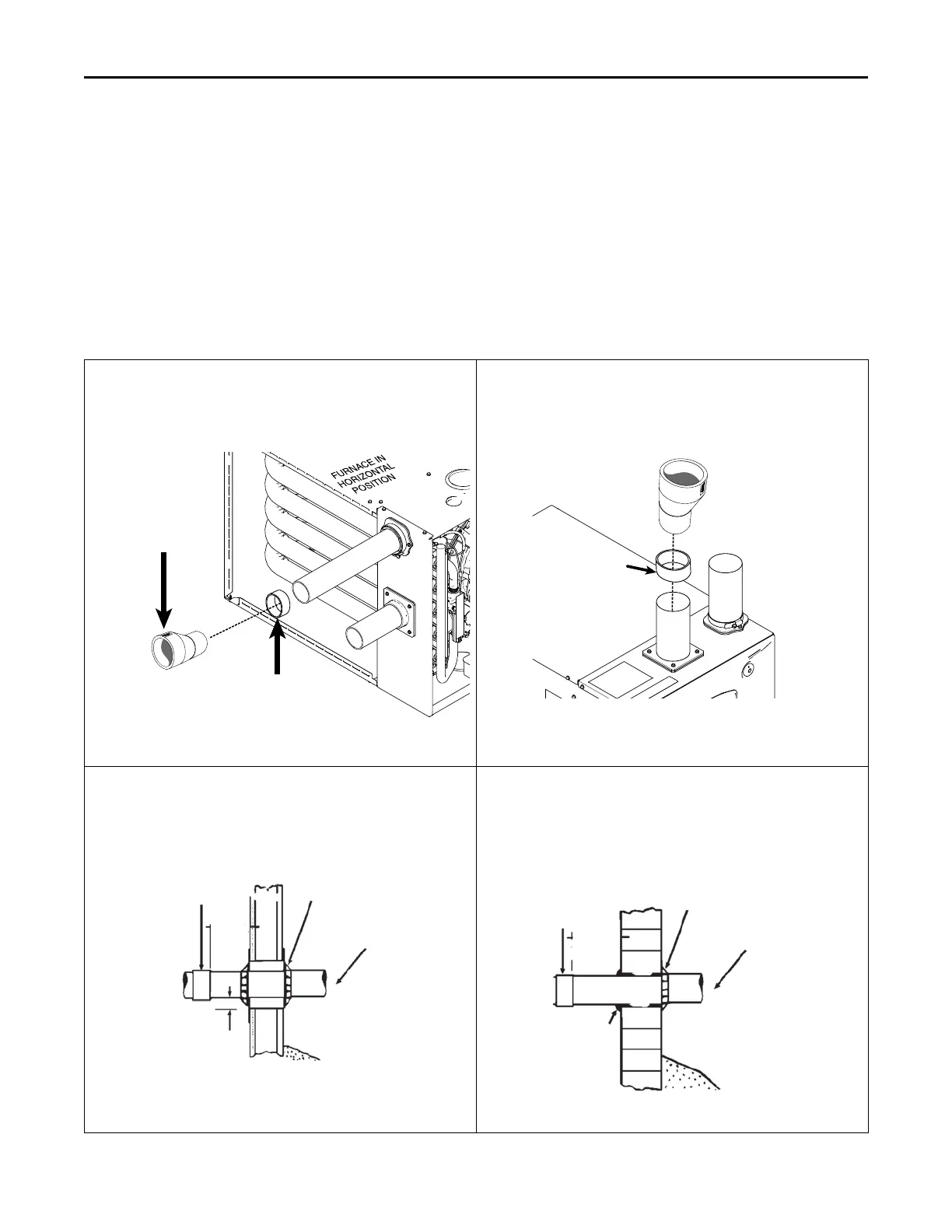

Horizontal Venting

Note: Insure that vent piping is sloped 1/4" per foot and that piping is supported properly to prevent sags and condensate pooling.

3” Venting requirements

Important: To determine if your application requires 3” venting, see the Maximum Vent Length Table.

Important: Horizontal venting application must use the 2” x 3” offset reducing coupling. Vertical venting applications do not require the

reducing coupling to be offset.

When the vent pipe is exposed to temperatures below freezing, e.g., when it passes through unheated spaces, etc., the pipe

must be insulated with 1/2 inch (12.7 mm) thick Armaflex-type insulation or equal.

If the space is heated sufficiently to prevent freezing, then the insulation will not be required. If domestic water pipes are not

protected from freezing then the space meets the condition of a heated space.

Note: If your furnace comes with a factory supplied 2" X 3" offset

reducing coupling it is used for 3" vent pipe installation. Make

sure the marking "TOP" is located on the top side of the pipe in

horizontal venting applications. The straight side of the

coupling must be on bottom for proper drainage of condensate.

Note: For Canadian applications, BAYREDUCE 2” x 3” offset reducing

coupling meets ULC-S636 requirements. Make sure the

marking "TOP" is located on the top side of the pipe. The

straight side of the coupling must be on bottom for proper

drainage of condensate in horizontal venting.

FIELD SUPPLIED

2” COUPLING

LABEL

SAYS

“TOP”

2" TO 3" COUPLING

CPL00938

BAYREDUCE may be used

in Canadian applications to

meet ULC-S636

CPL00938 IS FACTORY

SUPPLIED ONLY WITH THE

120,000 BTUH UPFLOW

FURNACE MODELS

FIELD SUPPLIED

2” COUPLING

2" TO 3" COUPLING

CPL00938 IS FACTORY

SUPPLIED ONLY WITH THE

120,000 BTUH UPFLOW

FURNACE MODELS

CPL00938

BAYREDUCE may be

used in Canadian

applications to meet

ULC-S636

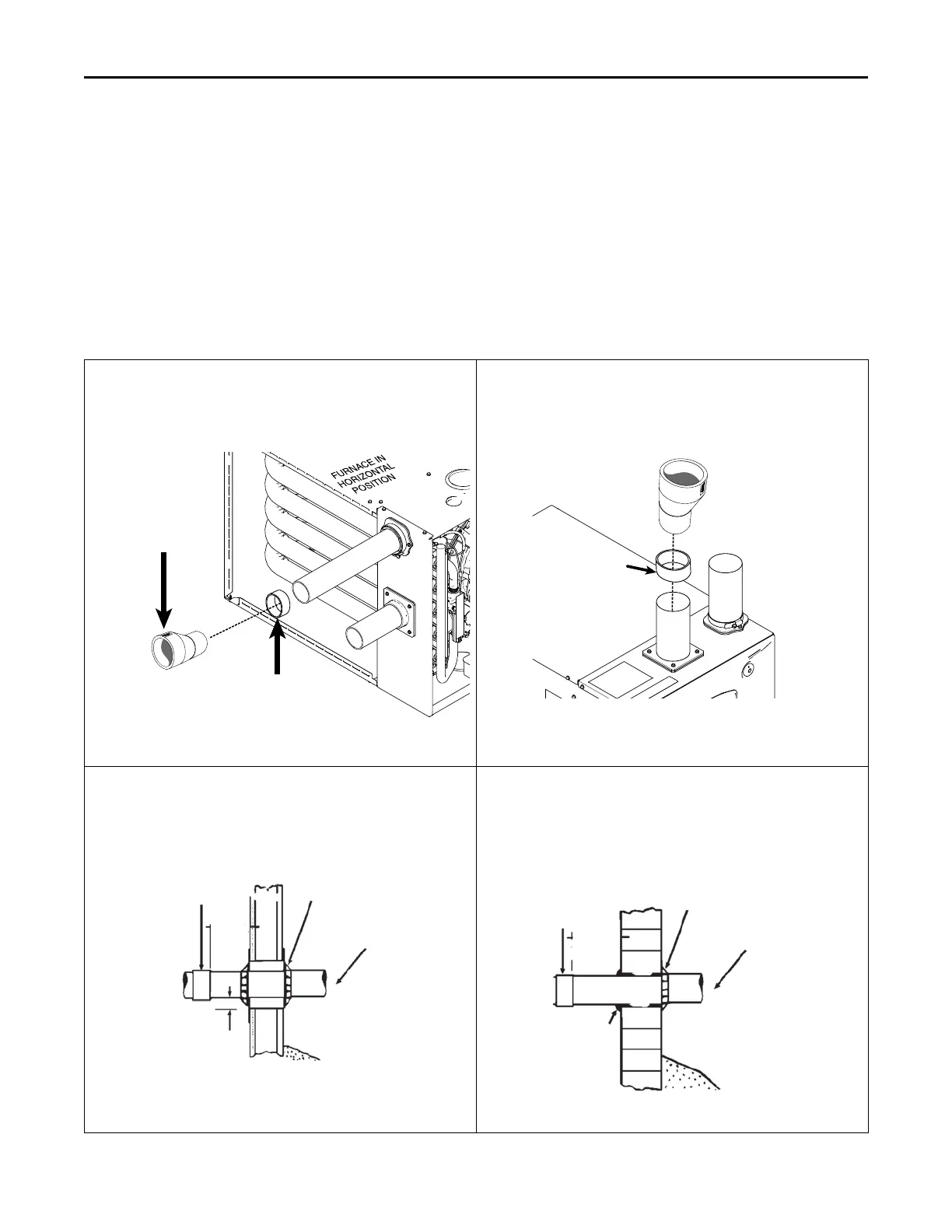

COMBUSTIBLE MATERIAL WALL

A minimum clearance of 1" to combustible materials must be

maintained when using single wall stainless steel venting.

Shield material to be a minimum of 24 gauge stainless or aluminized

sheet metal. Minimum dimensions are 12"x12". Shield must be

fastened to both inside and outside of wall. Use screws or anchor type

fasteners suited to the outside or inside wall surfaces.

NONCOMBUSTIBLE MATERIAL WALL

The hole through the wall must be large enough to maintain pitch of

vent and properly seal.

Use cement mortar seal on inside and outside of wall.

COUPLING

(PLASTIC

VENTING)

STUD

PVC WALL

MOUNT FLANGE

(OPTIONAL)

APPROVED

TERMINATION

1” CLEARANCE

(AIR SPACE)

VENTING THROUGH COMBUSTIBLE WALLS

Pitch - 1/4 Inch Per Foot

CLEARANCE (0” ACCEPTABLE FOR PVC VENT PIPE)

(1” ACCEPTABLE FOR TYPE 29-4C STAINLESS STEEL VENT PIPE)

12” MINIMUM ABOVE

NORMALLY EXPECTED

SNOW ACCUMULATION

LEVEL

6 IN. MIN.

(TO JOINT)

COUPLING

(PLASTIC

VENTING)

PVC WALL

MOUNT FLANGE

(OPTIONAL)

APPROVED

TERMINATION

CEMENT

MORTAR SEAL

INSIDE &

OUTSIDE

VENTING THROUGH NON-COMBUSTIBLE WALLS

Pitch - 1/4 Inch Per Foot

12” MINIMUM ABOVE

NORMALLY EXPECTED

SNOW ACCUMULATION

LEVEL

6 IN. MIN.

(TO JO

INT)

FFuurrnnaaccee GGeenneerraall IInnssttaallllaattiioonn

Loading...

Loading...