4 UNT-PRC002-GB

Technical Data

FWD 08 12 20 30 45

Power supply (V/Ph/Hz) 230/1/50

Capacities

Cooling capacity on water (1) (kW) 5,2 8,3 15 18,8 30,1

Heating capacity on water (2) (kW) 6,3 11,9 18,9 20,9 38,2

Fan motor (type) 2 x direct drive centrifugal

Fan power input (3) (kW) 0,23 0,46 0,65 1,04 1,51

Current amps (3) (A) 1,1 2,2 3,1 4,7 5,5

Start-up amps (A) 3,2 5,5 9,3 14,1 16,5

Air flow

minimum (m

3

/h) 490 980 1400 1800 2700

nominal (m

3

/h) 820 1650 2300 3000 4500

maximum (m

3

/h) 980 1970 2600 3600 5400

Main coil

Water entering/leaving connections (type) ISO R7 rotating female

(Dia) 3/4" 3/4" 1 1/2" 1 1/2" 1 1/2"

Electric heater (accessory for blower only)

Electric power supply (V/Ph/Hz) 230/1/50 230/1/50 or 400/3/50 400/3/50 400/3/50 400/3/50

Heating capacity (kW) 2/4 8 10 12 12

Hot water coil (accessory for blower only)

Heating capacity (4) (kW) 6,3 12 17,4 22,4 34,5

G2 filter (filter box accessory)

Quantity 2 2 2 2 2

Dimensions ( LxWxth) (mm) 386x221x8 486x271x8 586x321x8 586*421*8 586*621*8

G4 filter (filter box accessory)

Quantity - 2 2 2 2

Dimensions ( LxWxth) (mm) - 486x264x48 586x314x48 586*414*48 586*614*48

Condensate pump (accessory) (type) Centrifugal

Water flow - lift height (l/h - mm) 24 - 500

Not available for FWD30 and FWD45

Sound level (L/M/H speed)

Sound pressure level (5) (dB(A)) 36/40/43 38/41/44 46/50/53 47/52/57 47/52/58

Sound power level (5) (dB(A)) 46/50/53 48/51/54 56/60/63 57/62/67 57/62/68

Unit dimensions

Width x Depth (mm) 890 x 600 1090 x 710 1290 x 820 1290 x 970 1290 x 1090

Height (mm) 250 300 350 450 650

Shipped unit dimensions

Width x Depth (mm) 933 x 644 1133 x 754 1333 x 864 1333 x 1008 1333*1133

Height (mm) 260 310 360 460 660

Weight (kg) 32 46 61 76 118

Colour galvanised steel

Recommended fuse size

Unit alone (aM/gI) (A) 8/16 8/16 8/16 8/25 8/25

Unit with electric heater (gI) (A) 16 (2kW),25 (4kW) 40 (230V),3*16 (400V) 3*20 3*25 3*25

(1) Conditions: Water entering/leaving temperature: 7/12 °C, Air inlet temperature 27/19°C DB/WB - Nominal air flow

(2) Conditions: Water entering/leaving temperature: 50/45 °C, Air inlet temperature 20°C DB - Nominal air flow

(3) At high speed with nominal air flow.

(4) Water entering/leaving temperature 90/70 °C, air inlet temperature 20 °C DB, Nominal air flow.

(5) A rectangular glass wool duct 1m50 long is placed on the blower.The measurement is taken in the room containing the blower unit.

Heat exchanger operating limits:

FWD:

*water temperature: max 100° C

*absolute service pressure: min 1 bar/max 11 bars

Accessories - Hot water coil:

*water temperature: min. +2° C/max. 100° C

*absolute service pressure: min 1 bar/max 11 bars

CG-SVX051A-GB

34

Minimum/recommended water

content

The water volume is an important parameter because it

permit several things:

1. It avoids short cycle operation of the compressors.

Parameters which influence the minimum

compressor running time

− Water loop volume

− Load fluctuation

− Number of capacity steps

− Compressors rotation

− Dead band (adjustable on unit controller)

− Minimum running time of a compressor

2. On both chilled and hot water loops, it permits to

smooth water temperature fluctuations leaving the

CMAF unit whilst a circuit transitions from a mode to

another.

3. On hot water loop it permits to keep a leaving

temperature hot enough when defrosting cycles

occur :

− Assures the unit to defrost both circuits in a row

− Assures continuous operation and to run

Exchangers the most effective way.

For chilled water loop, the minimum water content shall

be in accordance with point 1.

For hot water loop, the minimum water content shall be

the maximum of recommendations #1 and #2.

1. Avoid short-cycles

For comfort application, we can allow water temperature

fluctuation at part load. The parameter to take into

account is the minimum operating time of the

compressor. In order to avoid lubrication problem on a

scroll compressor it must run at least 2 minutes

(120 seconds) before it stops.

The minimum volume can be determined by using the

following formula:

Volume =

With :

• Maximum unit capacity (kW) at full load

• time (seconds),120s minimum operating time

• step

high

(%),

• specific heat (kJ/kg) e.g.4.18 for water

• dead band (K) (default value see Table 9)

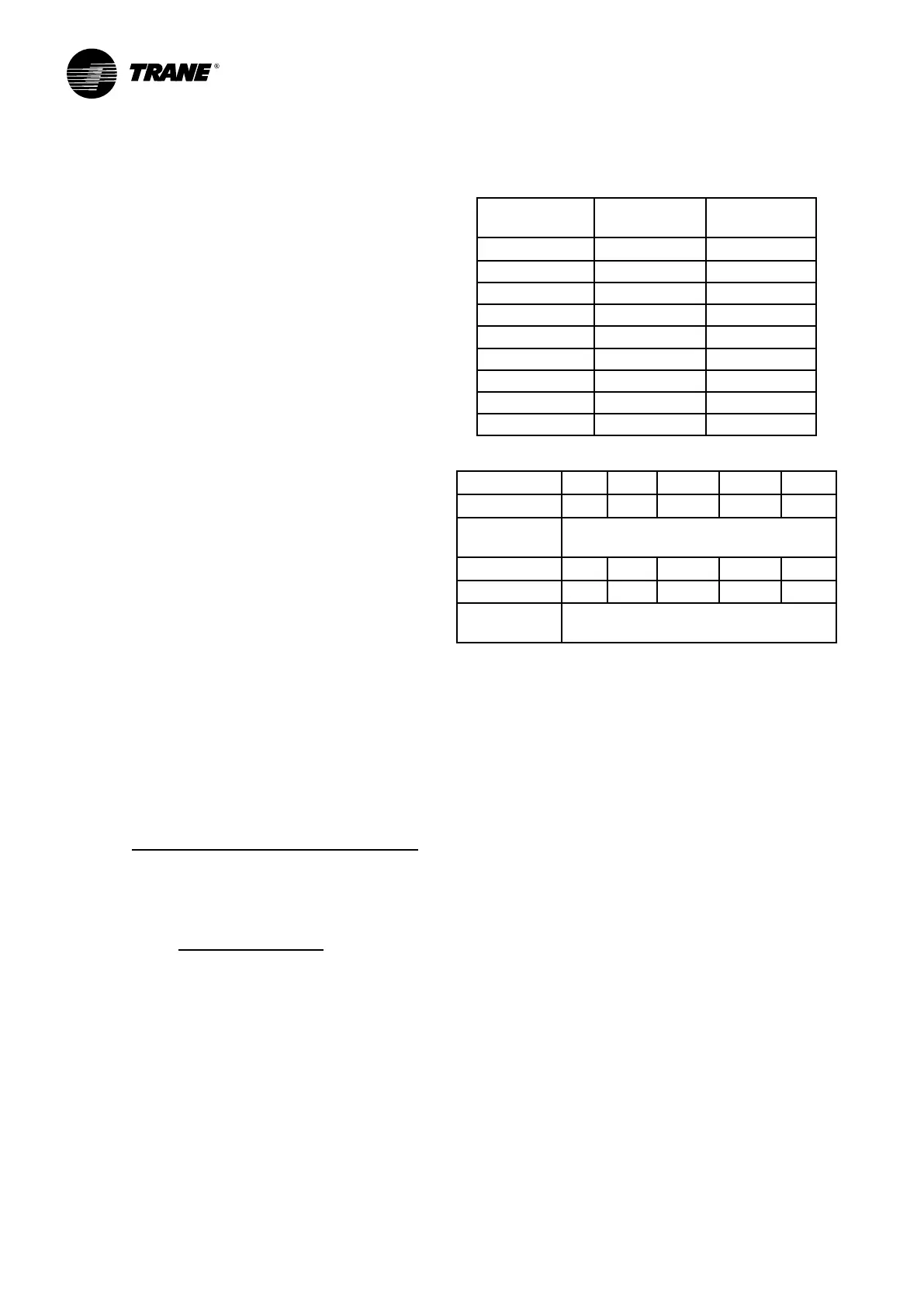

Table 8 – Brine specific heat (kJ/kg) at 30% concentration

Temperature

(°C)

Propylene

Glycol

Ethylene

Glycol

-10

4.80 4.30

0 4.44 4.22

10 4.18 4.07

20 4.00 3.87

30 3.86 3.65

40 3.72 3.41

50 3.55 3.18

60 3.31 2.97

70 2.96 2.80

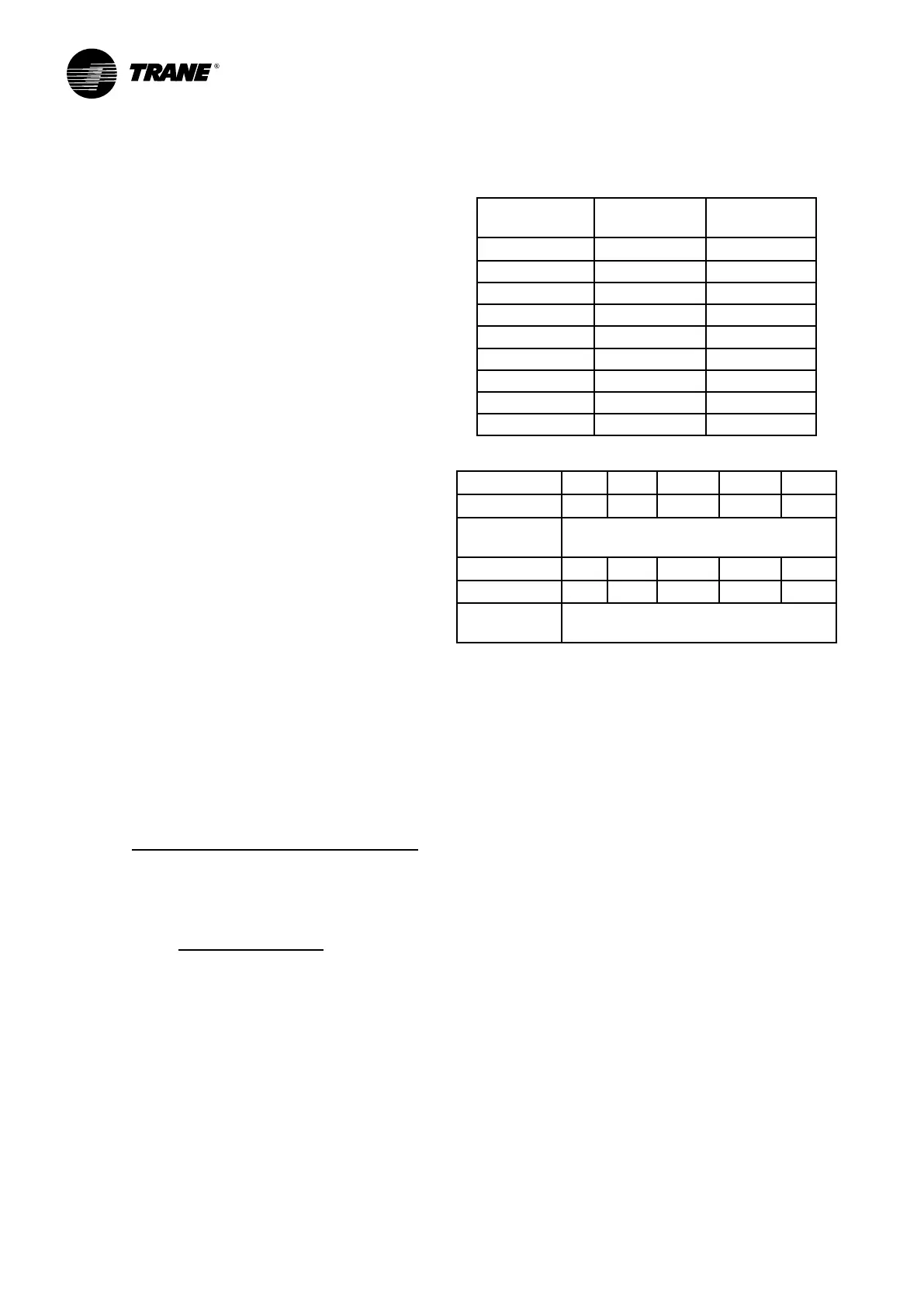

Table 9 - Default Dead band and highest compressor step

Unit Size 080 090 100 110 130

Highest Step 25% 27% 25%

29% 25%

Default Dead

Band

1.8

Unit Size 140 150 165 180 190

Highest Step 18% 17%

20% 18% 17%

Default Dead

Band

1.3

Note: To estimate the capacity, it is recommended

to make a selection at full load according ambient

temperature which the needs are the lowest and the unit

cooling/heating capacities the highest, e.g.

• The lowest ambient air temperature for cooling

mode

• The highest ambient air temperature for heat pump

mode.

It is also essential to take into account the brine specific

heat, in case of the use of glycol refer to Table 6.

Process applications will need more water volume to

minimize the water temperature fluctuation at part load.

2. Coil defrosting

When the unit is running in heat pump mode with

ambient air temperature below +7°C coils may be subject

to ice formation. The unit controller can initiate a defrost

cycle to melt the ice in order to recover a reasonable

capacity.

In case ambient air will not drop below +7°C

recommendations below do not apply.

The leaving temperature may be colder during few

minutes defrosting and shall be mixed into a buffer tank.

Chilled/hot water Piping

(largest compressorTonnage)

(unit tonnage)

(maximum unit capacity x time x step_high)

(specific heat x dead band)

Loading...

Loading...