Installer’s Guide

17

Two (2) problems typically arise when power venting

any oil fired appliance:

1) Soot buildup may occur at an accelerated rate on

critical components of the furnace oil burner, e.g.

the primary control flame sensor (“cad cell”), the

burner head, and oil nozzle.

2) Severe damage may occur to external surfaces of

the structure in the event the furnace continually

produces a high level of smoke in the flue gases.

Excess smoke and soot can be produced for many

reasons, some of which cannot be successfully con

-

trolled by the installer and the appliance manufac-

turer.

NOTICE: The manufacturer recommends the use of a

chimney to vent residential oil furnaces. If a power ven-

ter must be used, it is the responsibility of the installer

and power venter manufacturer to design, assemble,

and demonstrate proper operation of the power vent-

ing system with the furnace.

DUCT WORK AND AIR CONDITIONING

Air duct systems should be installed in accordance

with standards for air conditioning systems, National

Fire Protection Association Pamphlet No. 90. They

should be sized in accordance with ACCA Manual D or

whichever is applicable.

All furnaces are tested over a range of external static

pressure that simulates the airflow resistance of the

ductwork, fittings, and diffusers connected to the fur

-

nace for a typical (average) duct system. The furnace

blower and blower motor have been selected to work

successfully against the following range of duct system

resistance.

Recommended range of duct system resistance for all

models: 0.2 to 0.5 in. W.G. external static pressure.

Due to the need to maintain an adequate supply of

combustion and ventilation air, the furnace shall not

be installed in a small room without a return air duct

system.

A duct the full size of the furnace return air opening

shall extend to a location outside the furnace room.

If the furnace is used in connection with cooling/ heat

pump systems, a 3 " minimum long transition must be

installed between the furnace supply air outlet and the

evaporator coil supply air inlet to prevent overheating

of the evaporator coil drain pan. See page 10 for spe

-

cific layout and dimensions.

OVERHEATING HAZARD!

Failure to maintain a minimum of 3" separation from

the furnace heat exchanger and the evaporator coil

drain pan may cause drain pan damage.

If the furnace is used in connection with summer air

conditioning (cooling), the furnace should be installed

in parallel with, or on the upstream side of, the evapo

-

rator coil to avoid water vapor condensation in the fur-

nace heat exchanger.

If the cooling unit is installed in a parallel flow ar

-

rangement, dampers (or other means used to control

airflow) should be provided to prevent chilled air from

entering the furnace. If such a damper is manually op

-

erated, it must be equipped with a means to prevent

operation of either unit, unless the damper is placed in

either the full heat or full cool position.

NOTICE: Return air grilles and supply registers in the

air distribution system should never be obstructed.

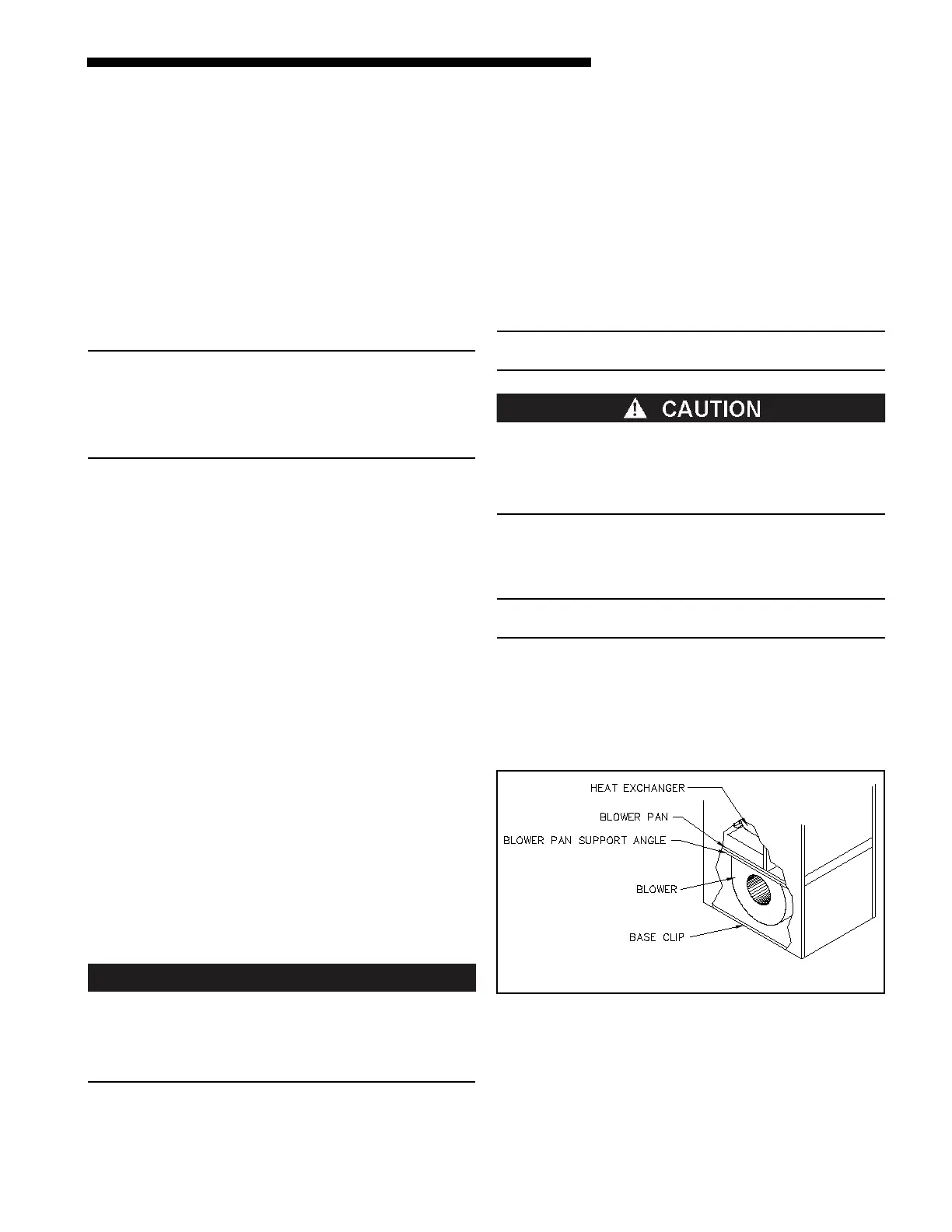

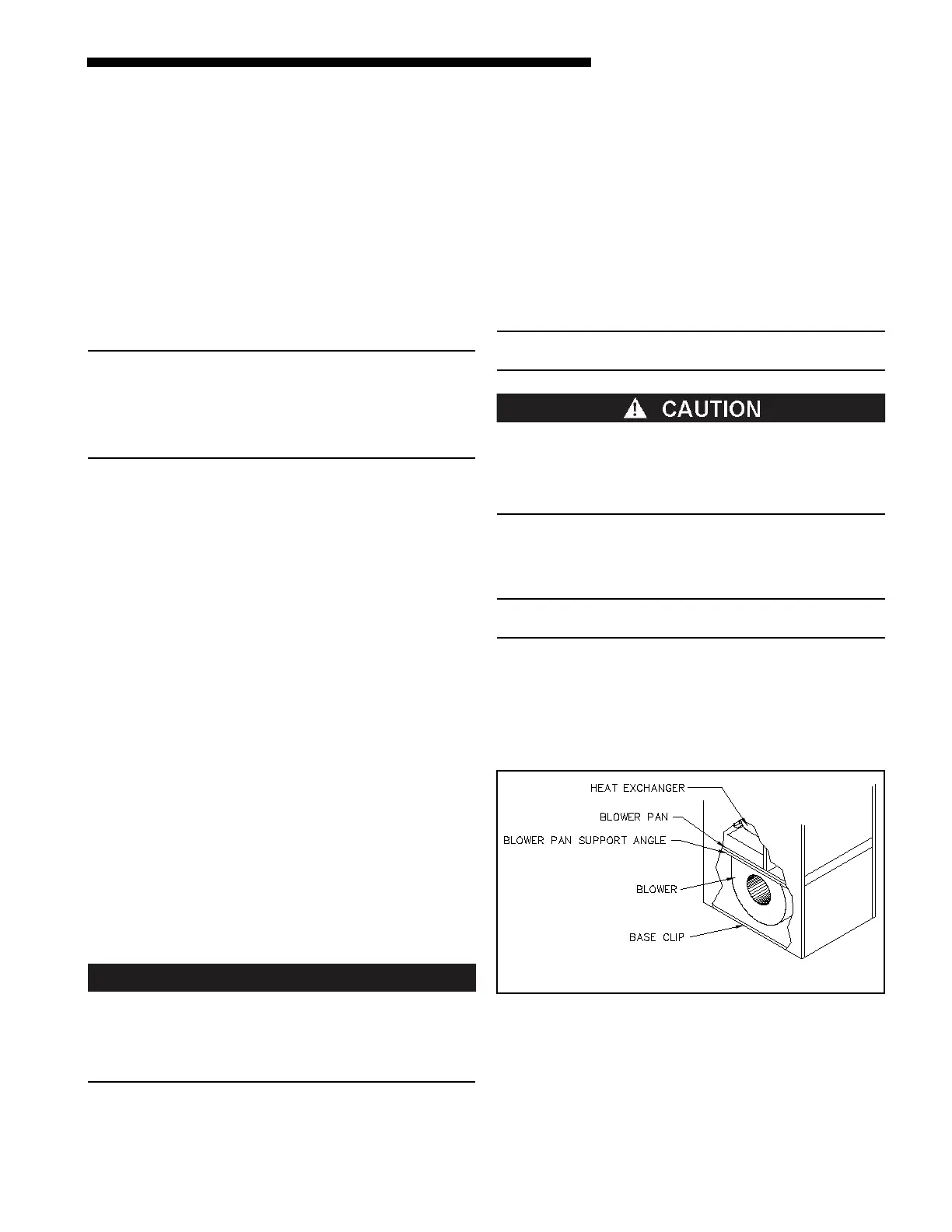

AIR FILTER MOUNTING

POSSIBLE CASING DAMAGE!

If cutting openings in the furnace casing is required,

DO NOT cut any supporting clips or angles. Cut as

close to the scribed line as possible, but DO NOT cut

the base clip or blower pan support angle.

Lowboy furnaces are factory-equipped with cleanable-

type, air filters located above the blower compartment,

in the rear of the furnaces. Highboy furnaces ship with

an external filter rack & cleanable-type filter.

NOTICE: Downflow/ horizontal furnaces are not factory-

equipped with an air filter or filter rack.

Furthermore, the furnace blower compartment does

not contain enough free space to permit an air filter to

be mounted within the furnace casing. The installer

should supply, or fabricate, a filter rack and mount an

air filter in the return air plenum above, or upstream

of, the furnace blower compartment.

w

Cutaway view of fan section

of a typical highboy furnace.

On the highboy furnace, it is necessary to cut the re-

turn air opening in the lower side, or rear, of the casing

depending upon the needs of the specific installation,

refer to Figure 12.

Loading...

Loading...