Installer’s Guide

20

• Install a generous capacity filter inside the build-

ing between the fuel tank shutoff valve and the

burner, locating both the filter and the valve close to

the burner for ease of servicing. Filter should be

rated for 50 microns or less.

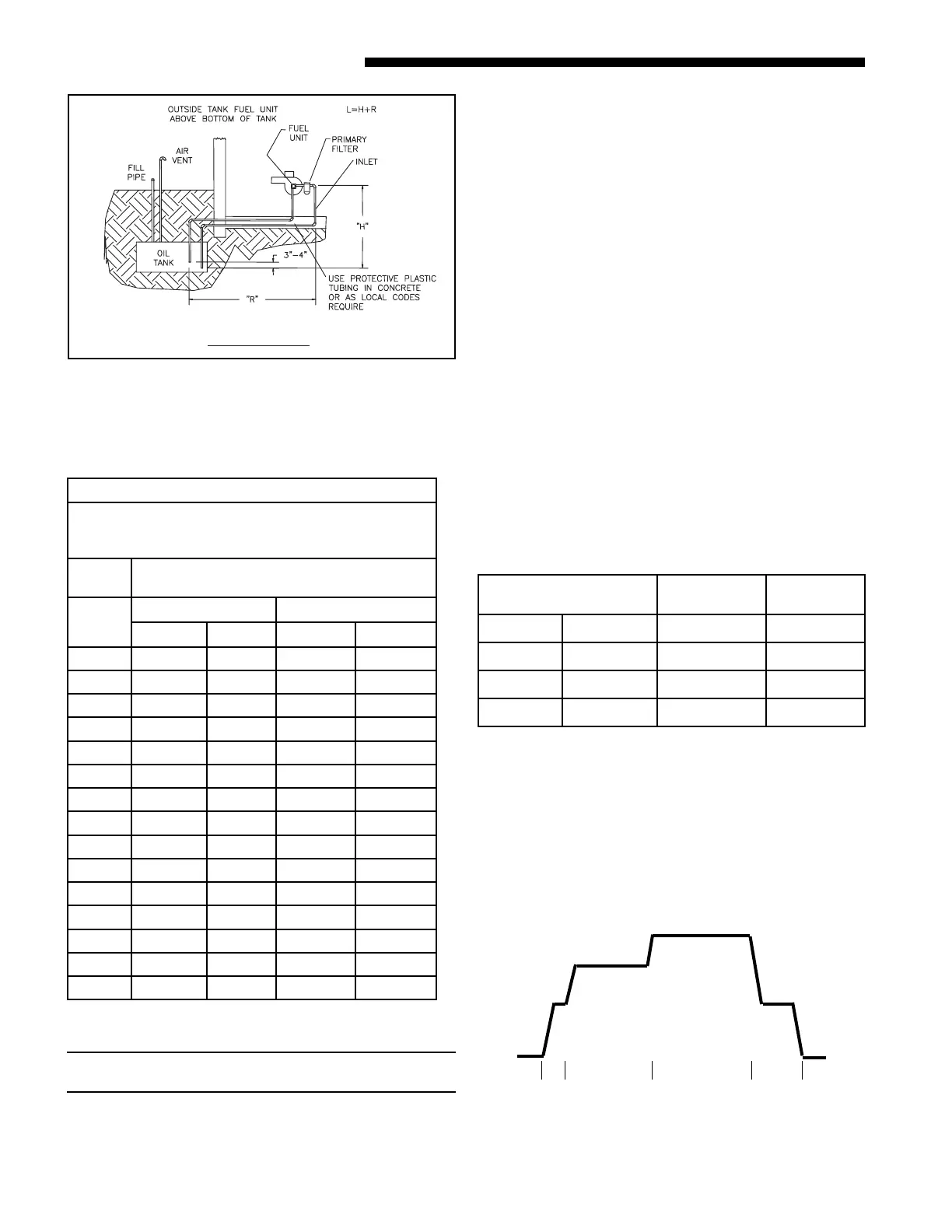

The following table and graph explain the delay-off set-

tings:

COOLING OFF - DELAY OPTIONS

SWITCH SETTINGS SELECTION

NOMINAL

AIRFLOW

5 - OFF 6 - OFF NONE SAME

5 - ON 6 - OFF 1.5 MINUTES 100% *

5 - OFF 6 - ON 3 MINUTES 50%

5 - ON 6 - ON ** 50 - 100%

TABLE 1

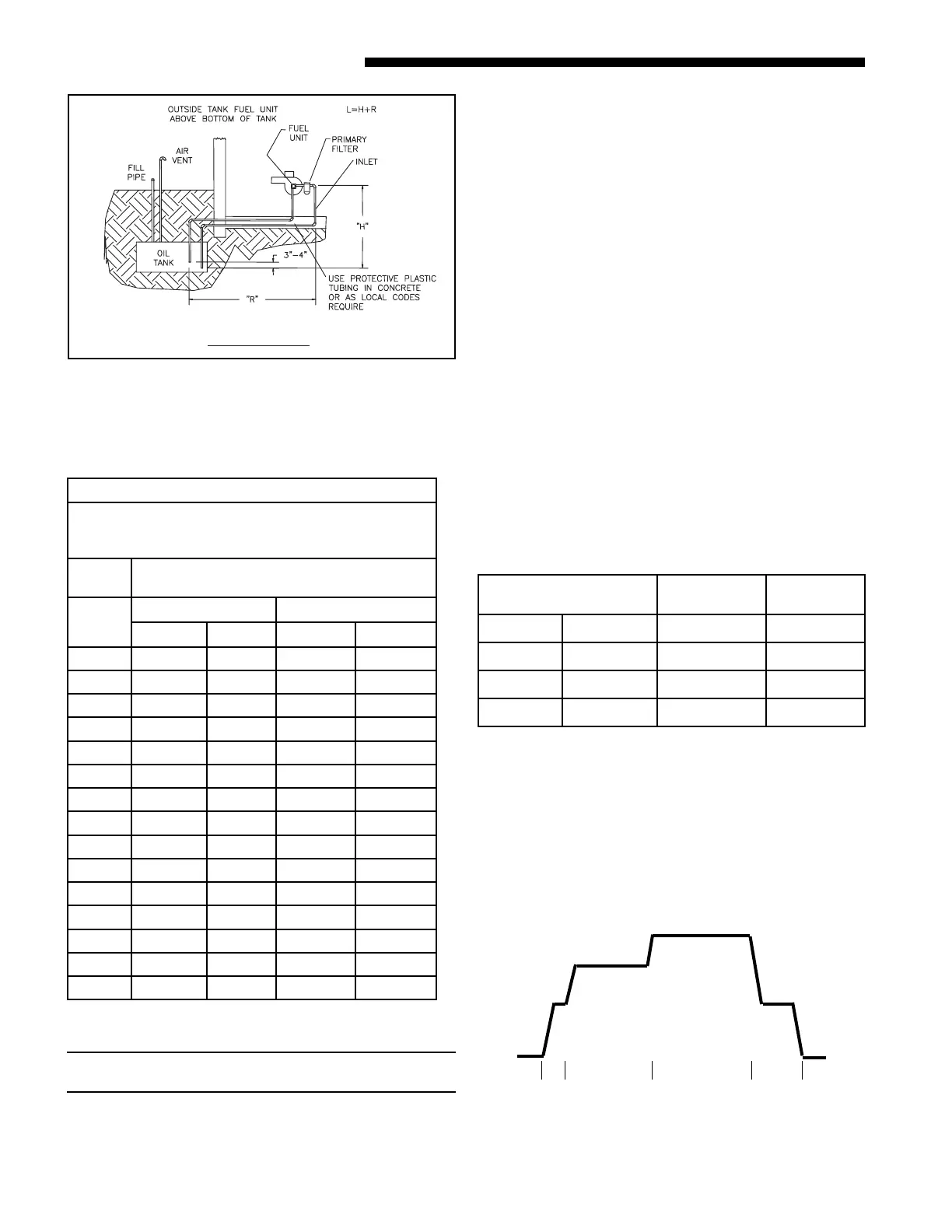

SINGLE STAGE, TWO PIPE

MAXIMUM LINE LENGTH

( H + R )

3450 RPM

Lift

"H"

3/8" Tubing 1/2" Tubing

3 GPH 7 GPH 3 GPH 7 GPH

0' 84' 71' 100' 100'

1' 78' 66' 100' 100'

2' 73' 62' 100' 100'

3' 68' 57' 100' 100'

4' 63' 53' 100' 100'

5 57' 48' 100' 100'

6' 52' 44' 100' 100'

7' 47' 39' 100' 100'

8' 42' 35' 100' 100'

9' 36' 31' 100' 100'

10' 31' 27' 100' 100'

11' 26' 22' 100' 87'

12' 21' 18' 83' 70'

13' - - 62' 52'

14' - - 41' 35'

VARIABLE SPEED DIP SWITCH SETTING FOR COOLING

t

SEE TABLE 1

0N PAGE 18

ELECTRICAL CONNECTIONS

NOTICE: All field wiring must conform to local, state,

and national installation codes.

A disconnect switch equipped with overcurrent protec-

tion (e.g. a time delay-type fuse or inverse time, cir-

cuit breaker) should be installed in the service line for

shutting down and protecting the furnace and electri

-

cal system.

Since the furnace is entirely pre-wired at the factory, it

is only necessary to connect the building electrical ser

-

vice lines to the two (2) pigtail wires extending from

the fan center junction box. The fan center is mounted

inside the furnace burner compartment or mounted

on the front exterior of the furnace, in the case of the

downflow / horizontal model. The service lines to the

furnace should be no smaller than 14 Ga., insulat

-

ed copper wire with a temperature rating of 60ºC, or

greater.

Connect an equipment ground wire to the furnace at

the fan center junction box. If wiring is run through

metal electrical conduit, it may not be necessary to run

a separate equipment ground wire. Consult local codes

and authorities for specific minimum requirements.

* - This setting is equivalent to BAY24X045 relay ben-

efit.

** - This selection provides ENHANCED MODE, which

is a ramping up and ramping down of the blower

speed to provide improved comfort, quietness,

and potential energy savings. See Service Facts

for cooling and heating air flow dip switch settings

1,2,3,4,7,8. The graph which follows, shows the

ramping process.

OFF

50%

50%

80%

Dehumidify

Efficiency

Fast Cooling

1

minute

3

minutes

7.5

minutes

100% if necessary

OFF

See Service Facts for dip switch setting

for complete setup for Enhanced Mode.

Loading...

Loading...