Dismantling Spring Wheel

DISMANTLING THE PLUNGER GUIDE BOX ASSEMBLY

P!unge;

Eiiide

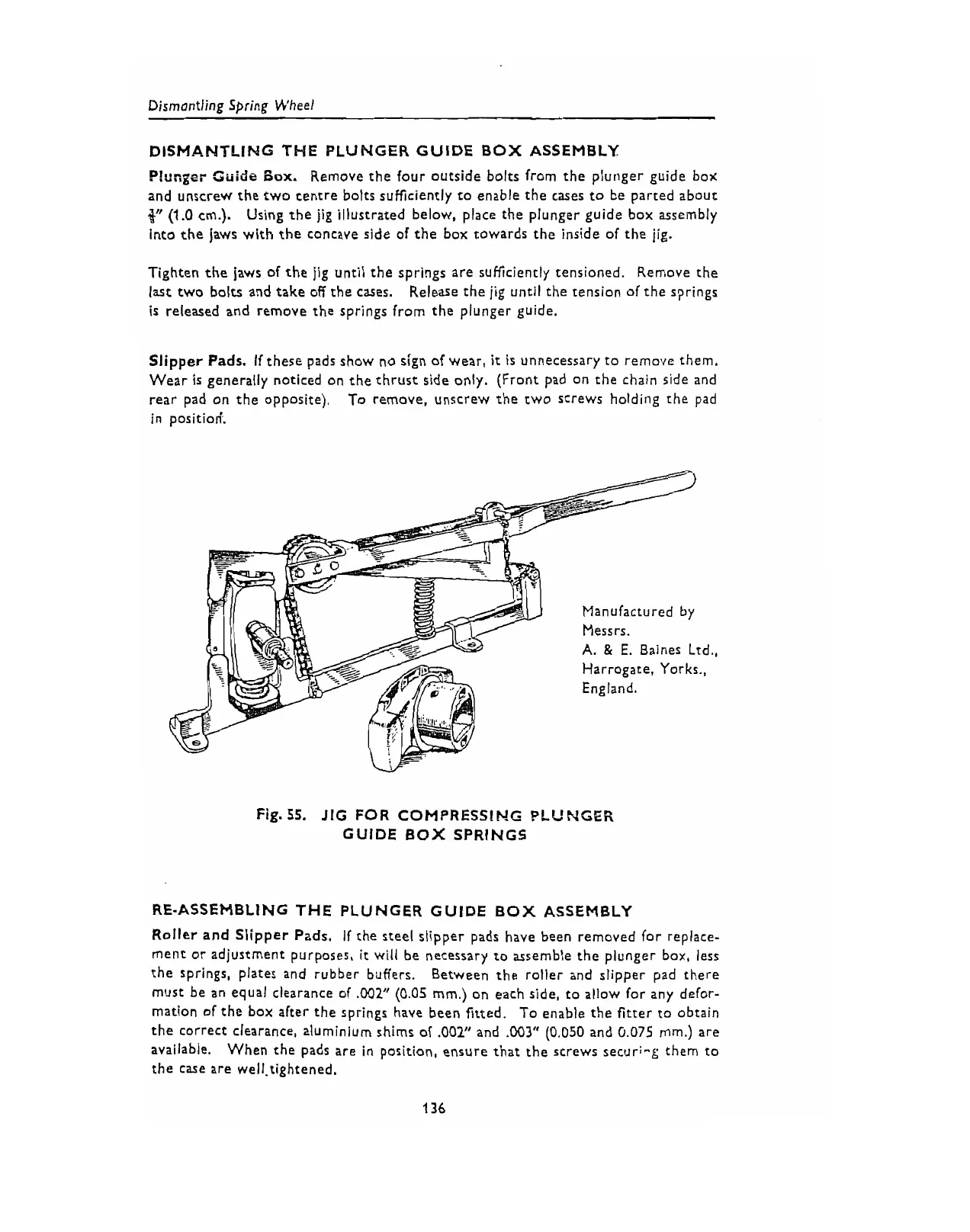

Box. Remove the four outside bolts from the plunger guide box

and unscrew the two centre bolts sufficiently to enable the cases to be parted about

+"

(1.0

cm.). Using the jig illustrated below, place the plunger guide box assembly

into the jaws with the concave side of the box towards the inside of the jig.

Tighten the jaws of the jig until the springs are sufficiently tensioned. Remove the

last two bolts and take off the cases. Release the jig until the tension of the springs

is released and remove the springs from the plunger guide.

Slipper

Pads.

If these pads show no sign of wear,

it

is

unnecessary to remove them.

Wear

is

generally noticed on the thrust side only. (Front pad on the chain side and

rear pad on the opposite). To remove, unscrew the two screws holding the pad

in position'.

Manufactured by

Messrs.

A.

&

E.

Baines Ltd.,

Harrogate. Yorks.,

England.

Fig.

55.

JIG FOR COMPRESSING

PLUNGER

GUIDE BOX SPRINGS

RE-ASSEMBLING THE PLUNGER GUIDE

BOX

ASSEMBLY

Roller and Slipper Pzds. if the steel slipper pads have been removed for replace-

ment or adjustment purposes,

it

will be necessary to assemble the plunger box,

less

the springs, plates and rubber bilffers. Between the roller and slipper pad there

must be an equal clearance of

,002"

(0.05

mm.) on each side, to allow for any defor-

mation of the box alter the springs have been fitted. To enable the fitter to obtain

the correct clearance, aluminium shims of

.002"

and

,003"

(0.050

and

0.075

mm.) are

available. When the pads are in position, ensure that the screws securi-g them to

the case are well.tightened.

Loading...

Loading...