11;spectiort

sf

Pistons

ond

Tcppcti

-

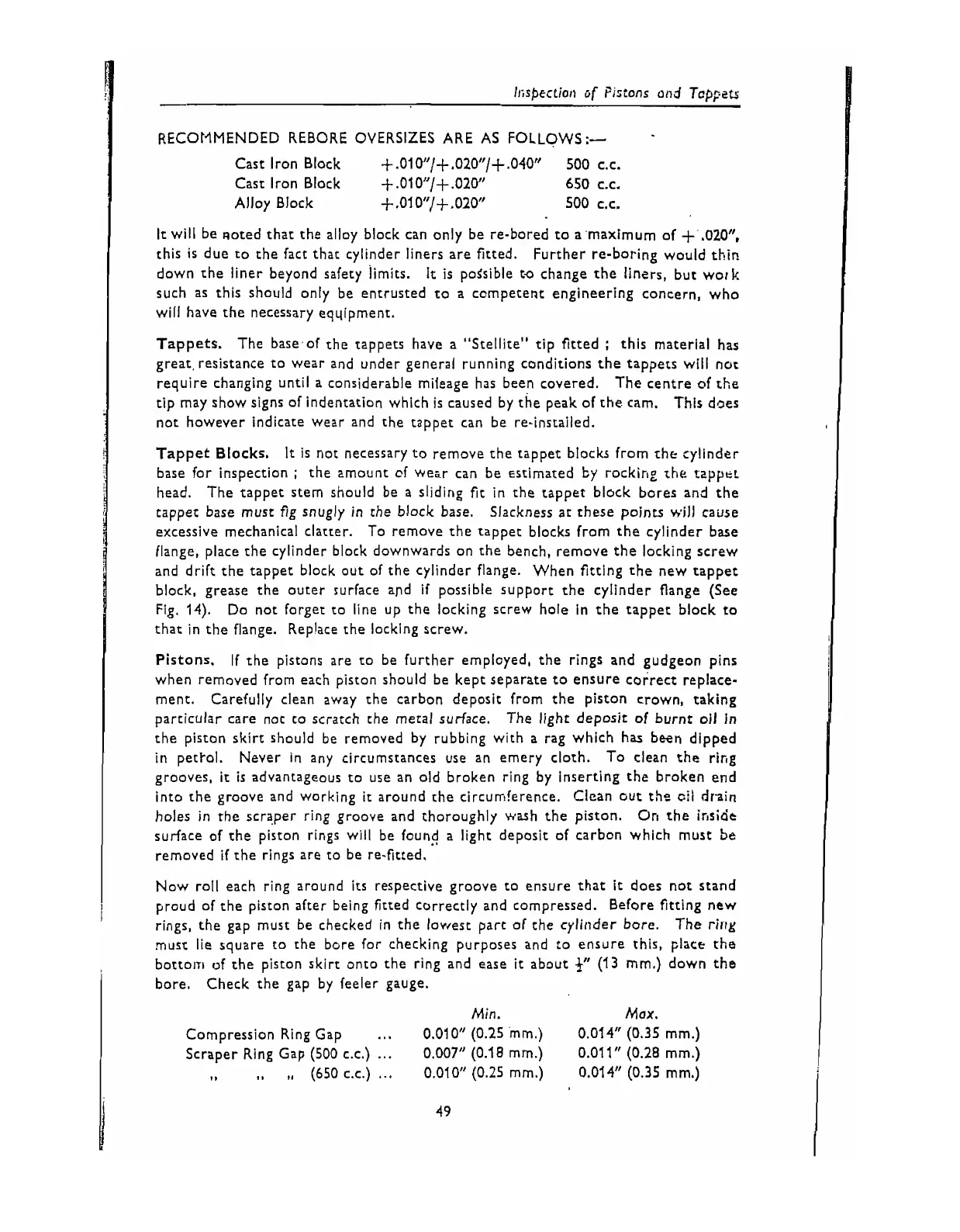

RECOMMENDED REBORE OVERSIZES ARE AS FOLLOWS:-

Cast lron Block +.010"/+.020"/+.040" 500

C.C.

Cast Iron Block +.010"/+.020" 650

C.C.

Alloy Block +.Olo"]+.020" 500

C.C.

It

w~li be noted that the alloy block can only be re-bored to a maximum of

+

.020°.

this

is

due to the fact that cylinder liners are fitted. Further re-boring would thin

down the liner beyond safety limits.

it

is pos's~ble

ta

change the liners, but work

such as this should only be entrusted to a competent engineering concern, who

will have the necessary eqqipment.

Tappets.

The base of the tappets have a "Stellite" tip fitted

;

this material has

grear resistance to wear and under general running conditions the tappets will not

require changing until a considerable mileage has been covered. The centre of the

tip may show signs of indentation which

is

caused by the peak of the cam. This does

not however indicate wear and the tappet can be re-insraiied.

Tappet Blocks.

It

is

not necessary to remove the tappet blocks from the cylinder

base for inspection

;

the amount of wear can be estimated by rocking rhe tapper

head. The tappet stem should be a sliding

fit

in the tappet block bores and the

tappet base must fig snugly in the block base. Slackness at these points wili cailse

excessive mechanical clatter. To remove the tappet blocks from the cylinder base

flange, place the cylinder block downwards on the bench, remove the locking screw

and drift the tappet block out of the cylinder flange. When fitting the new tappet

block, grease the outer surface and if possible support the cylinder flange (See

Fig. 14). Do not forget to line up the locking screw hole In the tappet block to

that in the flange. Replace the locking screw.

Pistons. If the pistons are to be further employed, the rings and gudgeon pins

when removed from each piston should be kept separate to ensure correct replace-

ment. Carefully clean away the carbon deposit from the piston crown, taking

particular care not to scratch the

metal surface. The light deposit of burnt

oil

in

the piston skirt should be removed by rubbing with a rag which has been dipped

in pettol.

Never in any circumstances use an emery cloth.

To clean the ring

grooves,

it

is advantageous to use an old broken ring by inserting the broken end

into the groove and working

it

around the circumference. Clean out the oii drain

holes in the scraper ring groove and thoroughly wash the piston. Or, the irkside

surface of the piston rings wili be found

a

light deposit of carbon which must be

removed if the rings are to be re-fitted.

Now roll each ring around

its

respective groove to ensure that

it

does not stand

proud of the piston after being fitted correctly and compressed. Before fitting new

rings, the gap must be checked in the lowest part of the cylinder bore. The rirry

must lie square to the bore for checking purposes and to ensure this, place the

bottom1 of the piston skirt onto the ring and ease

it

about

f"

(13 mm.) down the

bore. Check the gap by feeler gauge.

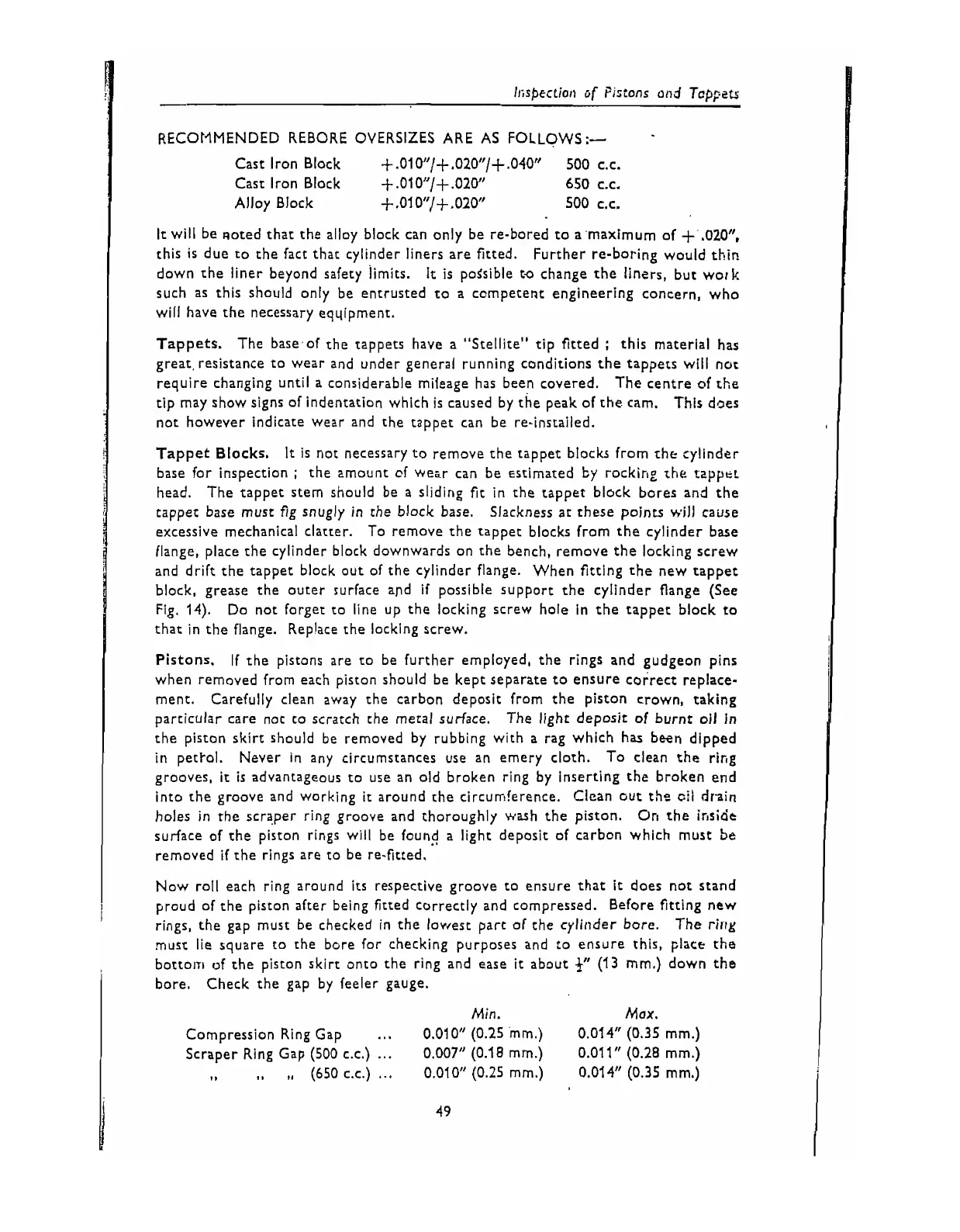

Min.

Max.

Compression Ring Gap

...

0.010" (0.25 mm.) 0.014" (0.35 mm.)

Scraper Ring Gap (500 c.c.)

...

0.007" (0.18 rnm.)

0.011" (0.28 mm.)

,,

..

,,

(650 c.c.)

...

0.010" (0.25 rnm.) 0.014" (0.35 mm.)

Loading...

Loading...