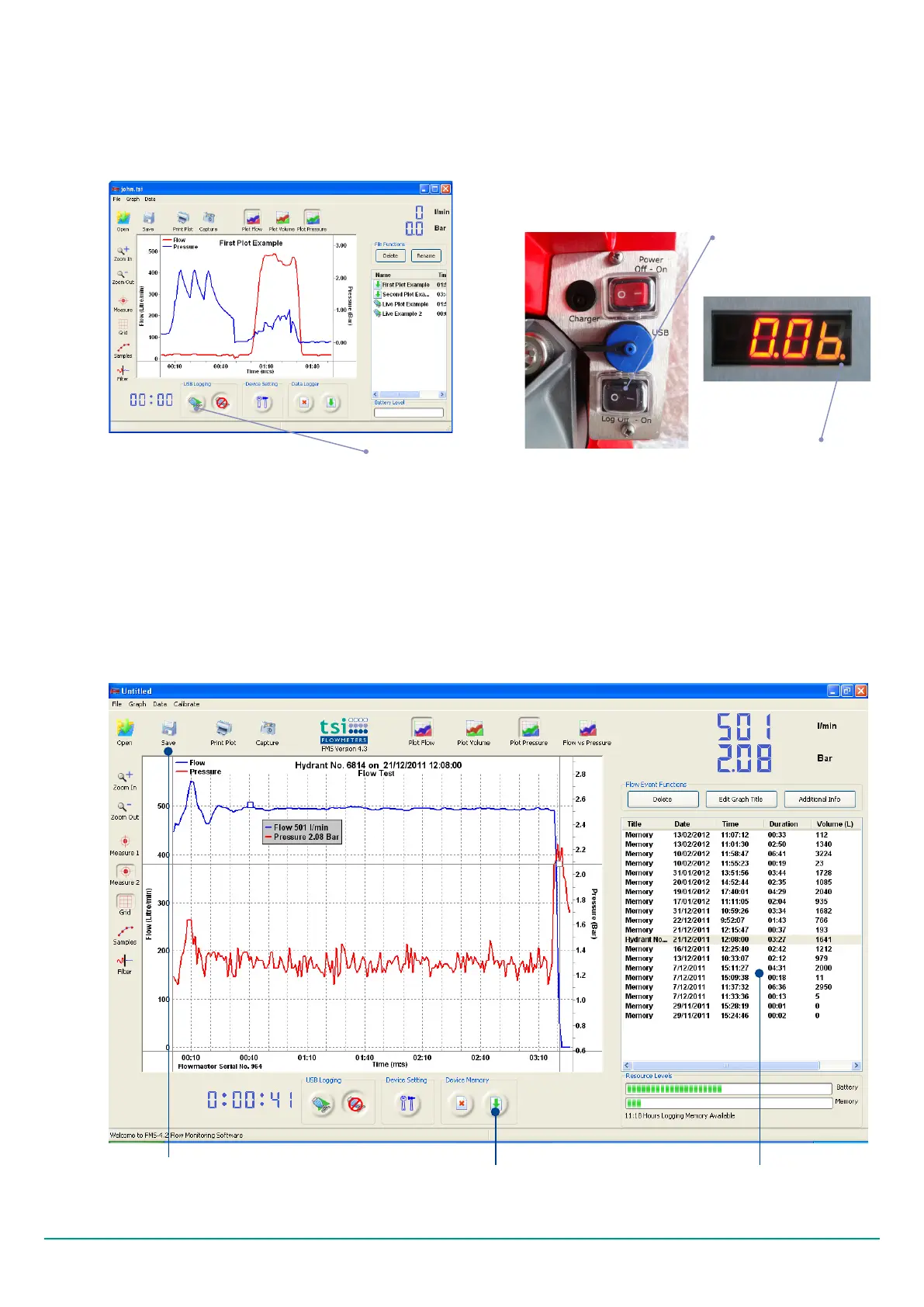

Fig. 4.17 Screen shot of user interface for the TSI Flow Monitoring software

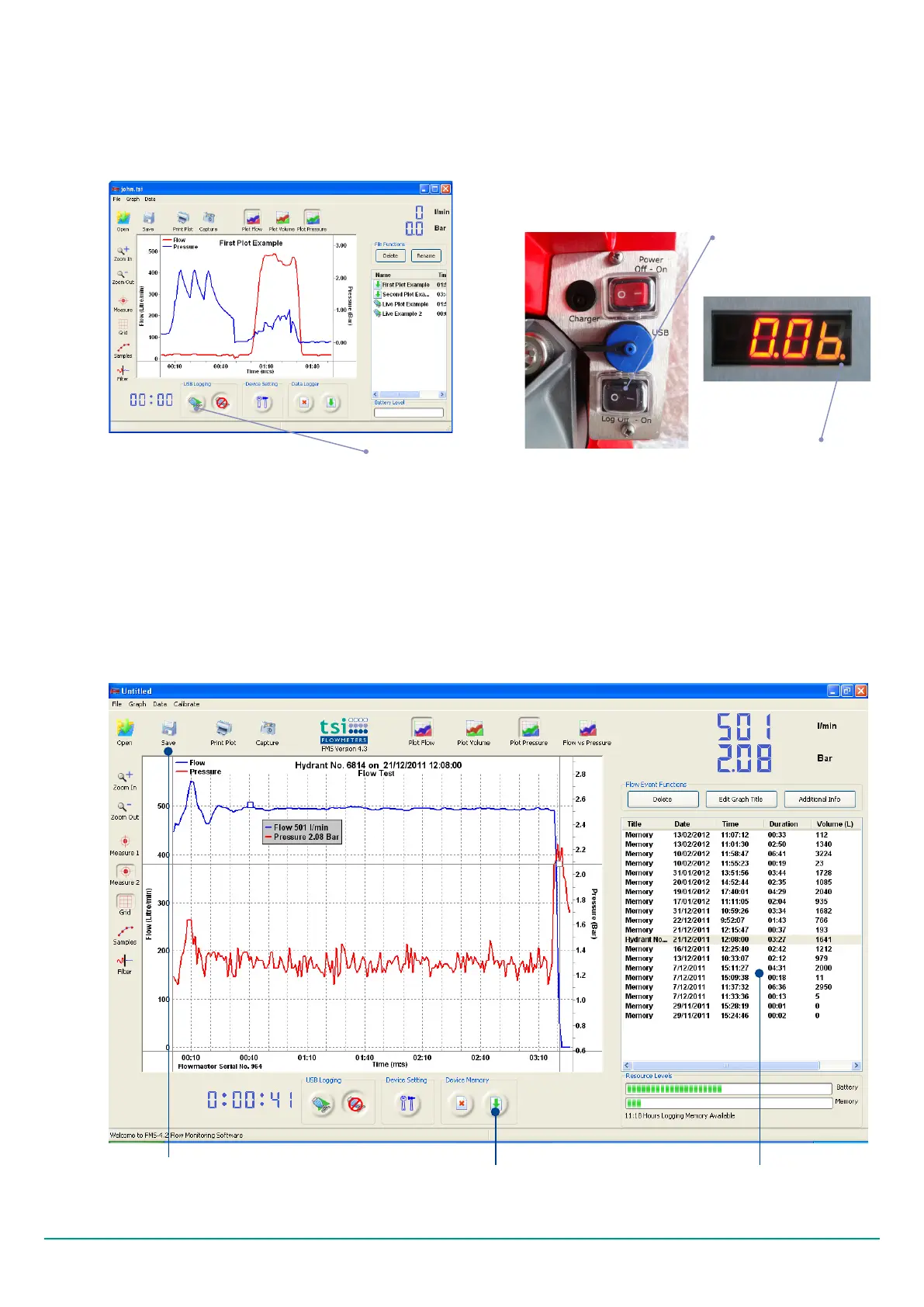

Fig. 4.16 Activating data log. The picture on right hand

side shows that the logger is recording. This is indicated

by the orange ‘dot’ on the bottom right

Switch to control manual

data logging

Logger recording ‘dot’

The Flowmaster data logger can display error messages

about the status of the data logger and about the status

of the Flowmaster 250DL. These error messages are as

set out in Table 1.

Log Files

Use the Save button to save your

log les to computer hard drive

Data Upload button

DATA LOGGING

The Flowmaster will log data as a stand-alone

instrument or directly to PC. Connect the Flowmaster

to your PC using the USB cable provided to live log.

Click the ‘USB Logging’ button on bottom of window

to begin data logging in live log mode.

4.5.2

When logging is in progress the recording ‘dot’ will light

up as shown in Fig. 4.16.

In manual mode, please press the black switch located at

the control panel of the Flowmaster to the ‘1’ position

to start logging ow and pressure. Take care that the

recording light is on. To stop logging, press the black

switch to the ‘0’ position.

In automatic mode, the logger will turn on and turn

off according to the ow rates and the conditions

established in software. The default activation ow rate

is 50 lpm and the default hysteresis ow rate is 30 lpm

continuously for ve seconds. Note, the recording light

will turn on when log conditions are met.

Fig. 4.14 Screenshot of FMS software with the live log

button highlighted

Live log button

The logger will store recorded data, even when the

meter is powered off.

Version 2.0 (February 2012) TSI Flowmeters Ltd.14

Loading...

Loading...