6-7

6 Vac System Testing - TLS-450PLUS Console Running a Manual Test

screen (below) and place each of the monitored Vac Sensors in EVAC HOLD (ref. Vacuum Sensor System

Troubleshooting Manual, P/N 577013-873).

3. At the 3-way ball valve connected to the tank’s interstitial riser cap, connect the external vacuum source to the

valve’s top barbed fitting. Rotate the valve handle to its up position and pull a vacuum down to -8 psi (-55.1

kPa), or if a relief valve is present, down to 1 psi (6.89kPa) above the relief valve’s opening pressure (e.g., if

relief valve opens at -7 psi [-48.26 kPa], pull the vacuum down to -6 psi [-41.36kPa]). When the desired

vacuum is attained, rotate the valve handle to its down position. Remove the external source from the valve’s

upper barbed fitting.

4. If necessary, repeat this procedure for the product line’s interstitial space, the vapor line’s interstitial space and

the double-wall containment sump’s interstitial space.

5. With all of the monitored interstitial spaces under vacuum, at the TLS Console, stop the EVAC HOLD for each

Vac Sensor. After a minimum wait of 12 minutes, monitor the Leak Rate and Time to No Vac display for each

Vac Sensor. Record the displayed values for each of the containment sump’s Vac Sensor in the chart in

Appendix A.

As a general guideline, the Time to No Vac should ideally be 100 hours, and should not be less than 24 hours.

Also, a Leak Rate greater than 22.4 gph (84.79 litre) will generate a Vacuum Warning. Both of these diagnos-

tics are indicators of whether the system has a significant vacuum leak.

If either diagnostic exceeds the guideline, the source of the leak should be corrected before the system is start-

ed up. Once the leak(s) is corrected, repeat steps 2-5.

6. When the monitored interstitial spaces under vacuum are within normal operating limits as described in Step 5,

fill the tank.

7. Once the tank is full, restore power to the pump.

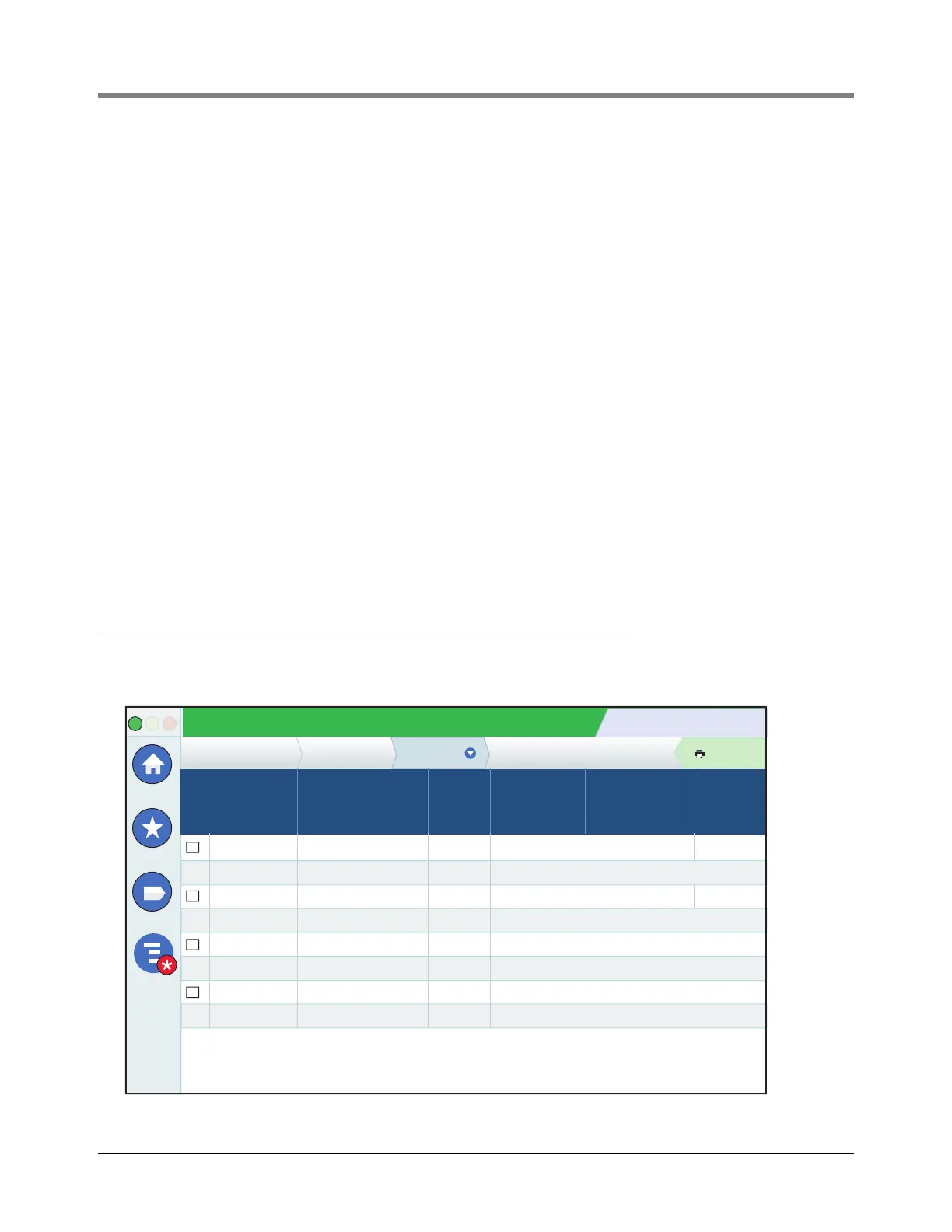

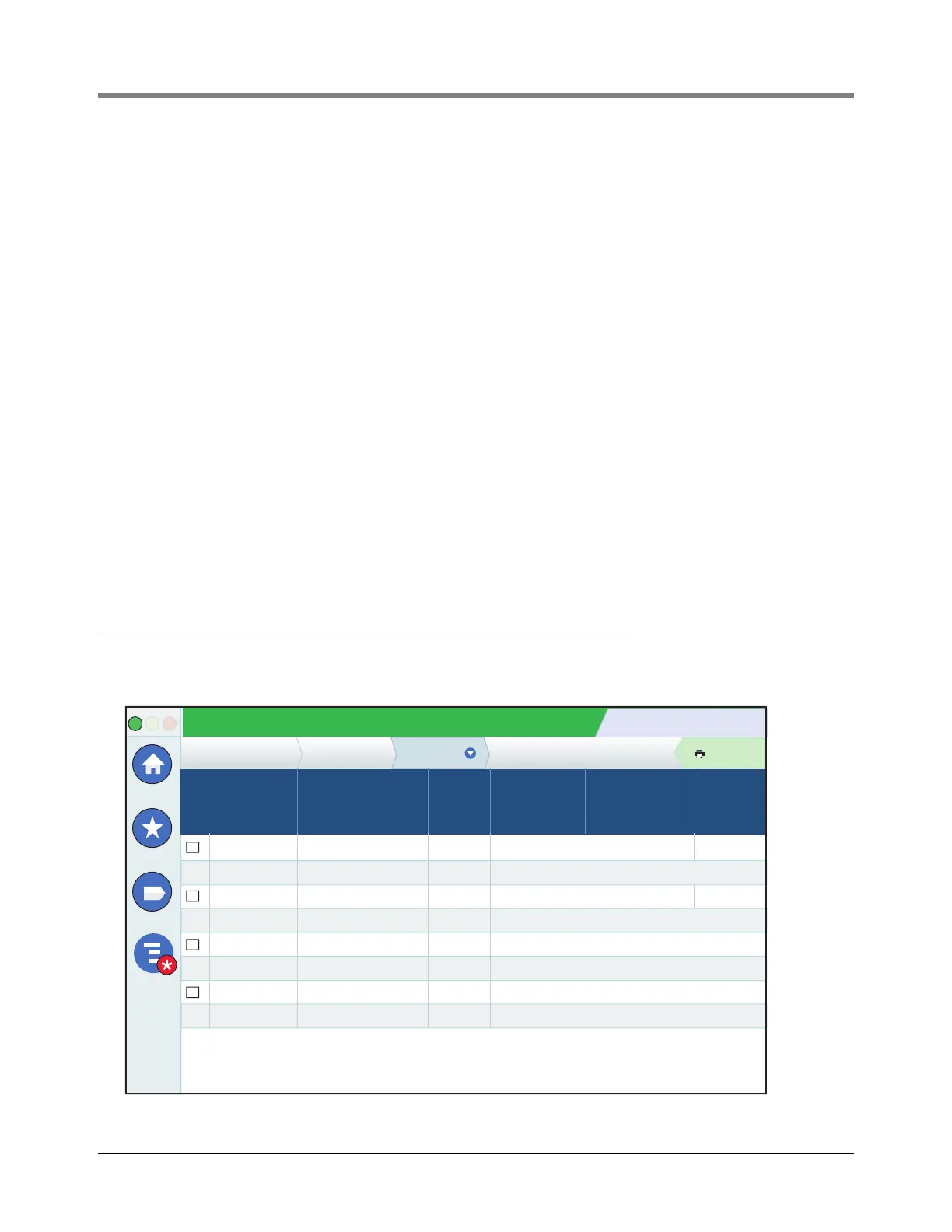

Running a Manual Test

1. Go to Menu>Diagnostics>Vac Sensor>Status screen. Select the box at the beginning of each row to

select an individual Vac Sensor.

System Status

10/16/2018 08:51 AM

0 Warning(s)

0 Alarms(s)

Print (0)

Actions

Diagnostics

Vs 1: Vac1 EVAC PENDING

VACUUM OK

VACUUM OK

VACUUM OK

-5.853

-9.000

-8.000

-8.000

9.998

0.000

0.000

0.000

Closed

Closed

Closed

Closed

3 : 3

100 : 0

100 : 0

100 : 0

Vac Sensor Status

Vac Sensor Evac State Valve

Pressure

(Comp)

[psi]

Time To

No Vac

HHHH:MM

Leak Rate

[gph]

Vs 2: Vac2

Vs 3: Vac3

Vs 4: Vac4

10/16/2018 08:51 AM

10/16/2018 08:50 AM

10/16/2018 08:51 AM

10/16/2018 08:50 AM

Home

Favorites

Menu

Loading...

Loading...