Part Number 550-110-639/0512

22

EG

•

PEG

•

EGH Gas-firEd boilErs — sEriEs 4 — boilEr manual

Connecting gas supply piping

1. Size gas piping considering:

a) Diameter and length of gas supplying piping.

b) Number of fittings.

c) Maximum gas consumption (including any possible

future expansion).

d) Allowable loss in gas pressure from gas meter outlet to

boiler.Forpressuredrops,seeANSIZ223.1.Canadian

installations must comply with CAN/CSA B149.1 or

B149.2 Installation Codes.

2. For natural gas:

a) Refer to Table 11 or the National Fuel Gas Code. To

obtain cubic feet per hour, divide the input by 1000.

b) Size for rated boiler input.

c) Inlet gas pressure: 5”

w.c. minimum

13”

w.c. maximum

d) Manifold gas pressure: 3Z\₂"

w.c.

e) Install 100% lock-up gas pressure regulator

in supply line if inlet pressure exceeds 13"

w.c., then

adjust for 13"

w.c. maximum.

3. For propane gas:

a) Inlet gas pressure: 11” w.c. minimum

13”

w.c. maximum

b) Manifold gas pressure: 10”

w.c.

c) Gas pressure regulator provided by gas supplier must

be adjusted for maximum pressure of 13”

w.c.

d) Contact gas supplier to size pipes, tanks and regulator.

4. Remove knock-out disc from jacket panel which gas

supply is to be piped.

5. Follow good piping practices.

6. Pipe joint compound (pipe dope) must be resistant

to corrosive action of liquified petroleum gases. Ap-

ply sparingly only to make threads of pipe joints.

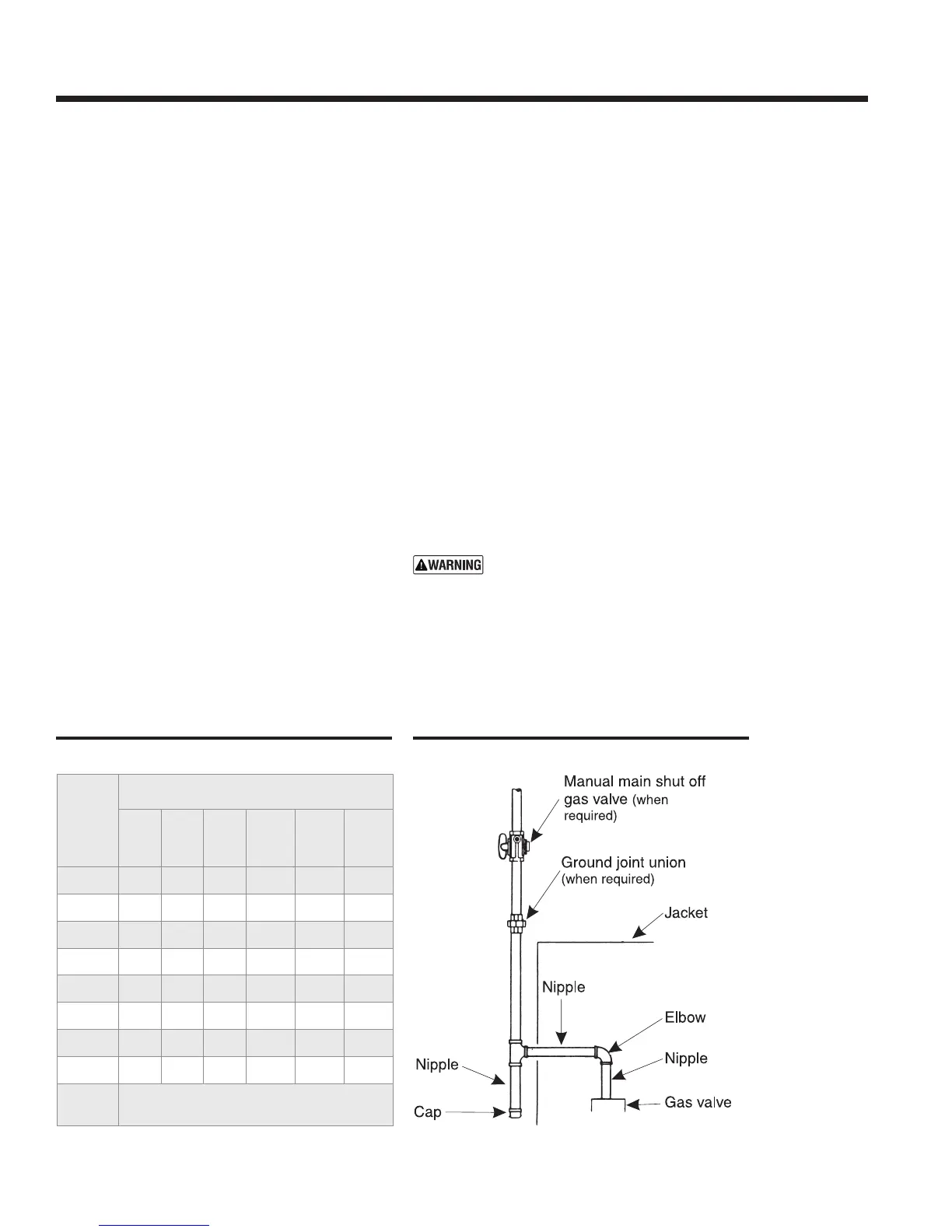

7. Install drip leg at inlet of gas connection to boiler.

Where local utility requires, extend drip leg to floor.

8. Install ground joint union when required for servic-

ing. See Figure 26.

9. Install manual shut-off valve outside boiler jacket as

shown in Figure 26 when required by local codes.

10. Support piping by hangers, not by boiler or its ac-

cessories.

11. In Canada only, the manual main shut off valve

(when used) must be identified by the installer.

12. Purge all air from piping.

13. Before placing boiler in operation, check boiler and

its gas connection for leaks.

Do not check for gas leaks with an open

ame–usebubbletest.Failuretodoso

can cause severe personal injury, death or

substantial property damage.

a) Close manual main shut-off valve during any pressure

testing at less than 13 inches water column.

b) Disconnect boiler and gas valve from gas supply pip-

ing during any pressure test greater than 13 inches

water column.

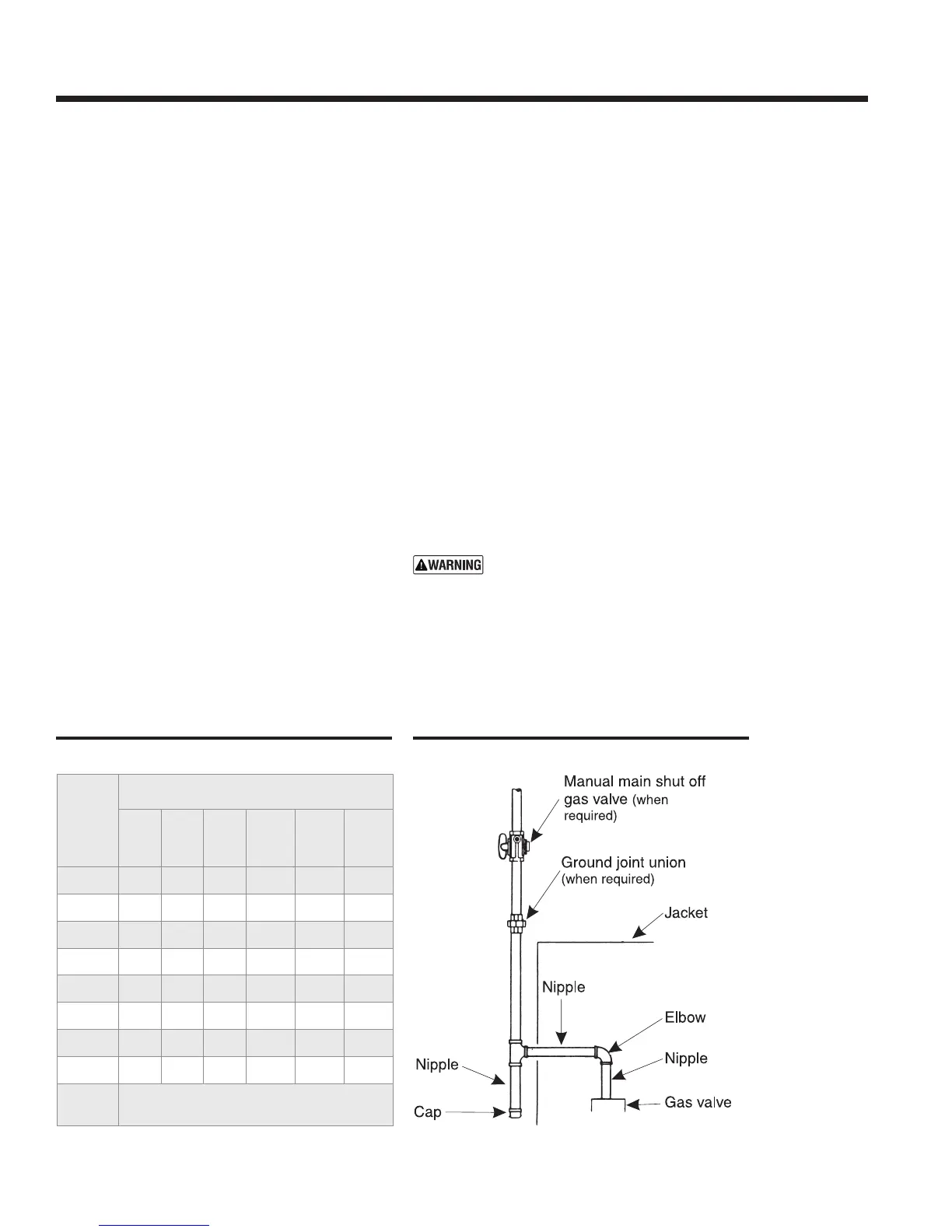

Adjusted

length

of gas

supply

piping in

feet *

Capacity of pipe sizes in

cubic feet of gas per hour **

¹⁄₂” ³⁄₄” 1” 1 ¹⁄₄” 1 ¹⁄₂” 2”

10 132 278 520 1,050 1,600 3,050

20 92 190 350 730 1,100 2,100

30 73 152 285 590 890 1,650

40 63 130 245 500 760 1,450

50 56 115 215 440 670 1,270

75 45 93 175 360 545 1,020

100 38 79 150 305 460 870

150 31 64 120 250 380 710

Notes

* Include measured length of gas supply piping and allowance

in feet for number and size of fittings.

** Specific Gravity - 0.60; Pressure Loss - 0.30” w.c.

Figure 26 Gas supply piping

Connect gas supply piping

Table 11 Gas pipe capacities

Loading...

Loading...