14. Replacement of Parts

14

.1.

WARNING.

Switch off

the

electricity

and

gas

supp

li

es before replacing

any

components.

After

the

replacement of any components, check for

gas

sound-

ness where relevant

and

carry

out

functi

ona

l checks

as

desc

ri

bed

in

Section

11

.

14.2.

COMPONENT ACCESS.

To

replace components it is necessary to remove one or more sec-

tions

of

the

cab

in

et

and

cover

plates

within

the

appliance

as

described

in

Section 13.3 together with

the

facia

and

control box

as

described in the

notes

fo

llo

wing.

(a)

Facia. Remove

the

inner cover

pane

l

as

described in Section

13.3

(b)

. Remove

the

three screws which hold the facia assem-

bly

in

position. Lower the fascia assembly. The assembly can

be unhooked from its supports.

Do

n

ot

allow

it

to hang unsup-

ported. See

Fig

. 20.

(b)

Control Box. Remove

the

inner cov

er

pane

l

as

described in

Section 13.3

(b)

. Unscrew

the

two fixing screws

at

each end of

the control box.

Pull

the

complete assembly forward and

lo

wer

if

necessary.

The

assembly can be unhooked from its support

s.

Do

not allow it to

hang

unsupported. See

Fig

. 22.

Important

: The

fo

llo

wing components are secured to

the

appli-

ance with clips. See

Figs.

37

,

38

and

39

.

12

: Expansion

Vessel

13: Central Heating Pump

14: Domestic Hot Water Pump

15:

Wa

ter to Water Heat Exchanger

27: Gas to Water Heat Exchanger

Important

:

Co

mprehensive gasket/ 0-ring packs are available for

the

gas

and water connections on

the

appliance. See Section 15.

When replacing

th

ese components

the

connections

must

be fully

entered so

that

the clips can

pa

ss

completely into t

he

locating

groove.

The

clips must

not

be forced into place.

Any

'0' ring which shows sign of damage

must

be replaced.

Th

e

'0

' rings

can

be

lubricated

wi

th

a suitable lubricant

(i.e

. silicon

based

grease

or

glycerin) which is

non-reactive

with

the

eth

y-

lene- propylene nit

ril

e '0 ' rings.

14.3.

DRAINING THE APPLIANCE

Check

th

at

the

electricity supply to

the

appliance is turned

off.

Before removing any compon

ent

holding

water

, it is impo

rt

ant

that

as

much

wa

ter

as

poss

ibl

e is removed from the appliance.

(a)

Appliance Central Heating Circuit

Turn

off

the

central heating

flow

and return valves

at

the

app

li

-

ance.

See Figs.

21

and

28. These

are

operated

us

ing

an

adjustable s

pa

nn

er

or

a screwdriver.

Fit

a

tube

to the drain tap

and

open

the

tap

about

one turn.

See

Fig

.

28

. Pre

ss

in

the

non-return

valve

test

button

on

the

central he

at

ing

pu

mp

(left hand) to remove more water. See

Fig

. 39. Close the drain tap when the flow has stopped.

Some

water

will

remain in the expansion vessel,

pumps

and

Gas to Water he

at

exch

anger

and

extra care

must

be

taken

when removing these components.

(b)

Appliance Hot Water Circuit

Turn off

the

mains

water

supply

va

lve

at

the appliance. See

Figs

. 21

and

28.

Thi

s is operated using a flat blade screwdriver.

Later versions of

th

e water flow regulator have a drain screw

which

must

be loosened to remove more water. See Fig.

41

.

A

quantity

of

water

will remain

in

th

e

Wa

ter to Water

heat

exchanger

and

extra care

mu

st

be

taken when removing this

component.

23

14

.

4.

COMPONENT REPLACEMENT.

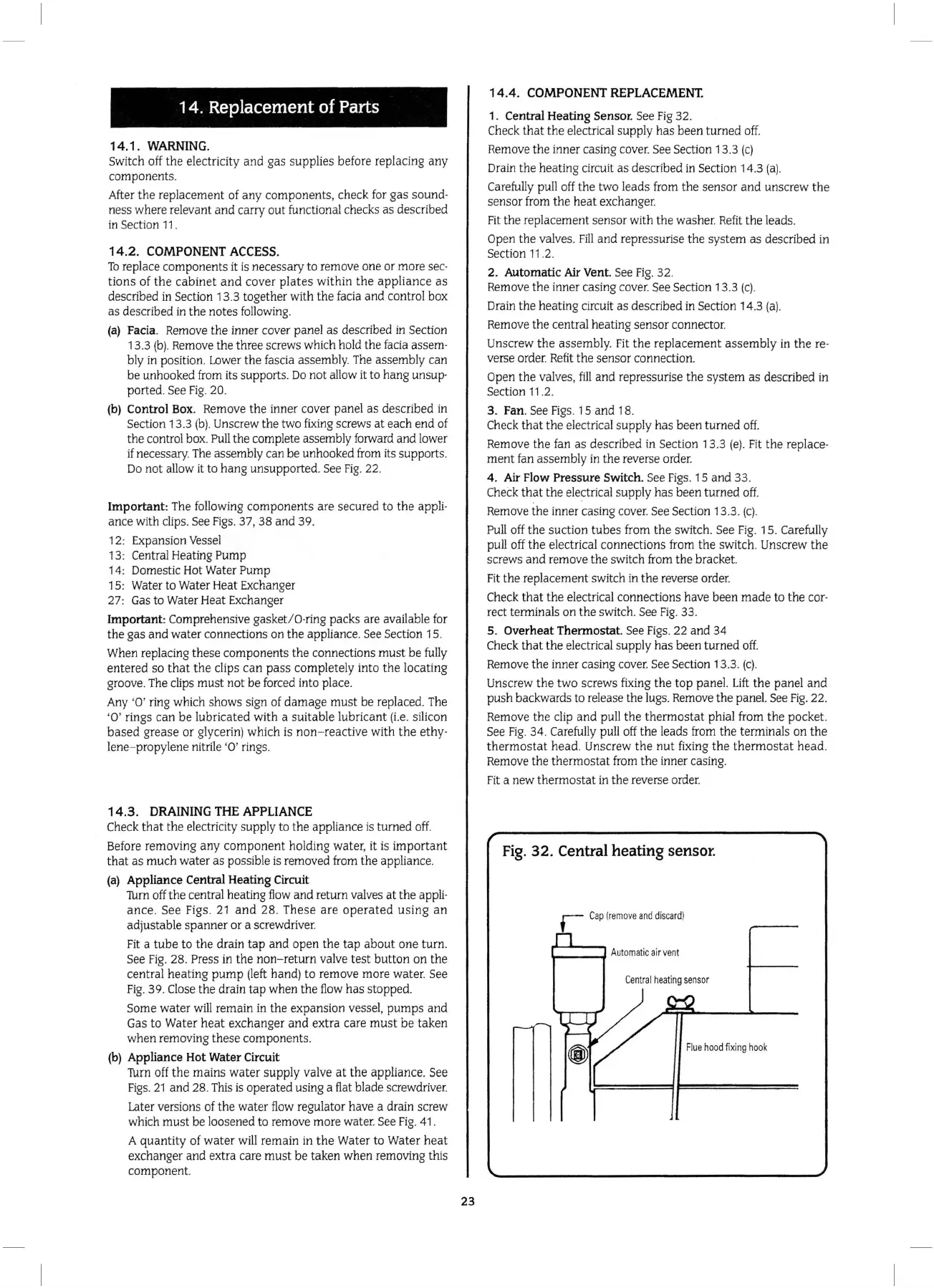

1. Central Heating Sensor. See

Fi

g

32

.

Ch

eck th

at

the

electrical supply has been turned off.

Rem

o

ve

the

inner casing cover. See Section 13.3

(c)

Drain

the

he

at

in

g circuit as described

in

Secti

on

14.3 (a

).

Ca

refu

ll

y pull

off

the

two leads from

the

sensor

and

unscrew

th

e

sensor from

th

e

heat

exchanger.

Fi

t the replacement sensor with the washer.

Refi

t

the

leads.

Open the

va

lves.

Fill

and

repressuri

se

the syst

em

as

described

in

Section

11

.2.

2. Automatic Air Vent.

See

Fig

. 32.

Remove

the

inner casing cover. See Section 13.3

(c)

.

Drain

the

heating circuit as described in Section 14.3 (a).

Remove

the

central

hea

ting sensor connector.

Unscrew

the

assembl

y.

Fit

the

repl

acement

as

sembl

y in

the

re-

verse order.

Re

fi

t the sensor connection.

Op

en

the

va

lves,

fill

and

re

pr

essuri

se

the

system

as

described

in

Section

11

.2.

3. Fan.

See Figs. 15

and

18.

Check

that

the

electrical supply has been turned off.

Remove

the

fan as describ

ed

in

Se

ct

i

on

13.3 (

e).

Fit

the

replace-

ment

fan

ass

embly

in

the reverse order.

4. Air Flow Pressure

Sw

it

ch

. See

Figs

. 15 and

33

.

Ch

eck

th

at

th

e electrical supply has been

tu

rned

off.

Rem

ove

the

inner cas

in

g cover. See Section 13.3. (

c)

.

Pull

off

the

suction tu

bes

from

the

switch.

Se

e

Fig

.

15

. Carefully

pull off

the

el

ectrical connections

fr

om

the

switch. Unscrew the

sc

rews

and

remove

the

switch from

the

bracket.

Fit the replacement switch in

the

reverse orde

r.

Check

that

the

electrical connections have been

made

to the

cor-

rect terminals on

the

switch. See

Fig

.

33

.

5. Overheat Thermostat. See Figs.

22

and

34

Ch

eck

that

the

electrical su

pp

ly has been turned off.

Rem

ove

the

inner casing cover. See Section 13.3.

(c).

Unscrew

the

two screws fixing

the

top panel.

Lift

the

panel

an

d

push

backwards to release the lugs. Remove the panel.

Se

e

Fig

.

22

.

Rem

ove

the

cl

ip and

pu

ll

the

thermostat

phial from the pocket.

See Fi

g.

34

. Carefully pull

off

the

leads from the terminals

on

th

e

thermostat

head

. Unscrew

the

nut

fixing

the

thermo

stat

head

.

Remove

the the

r

mostat

from

the

inner casing.

Fit

a new

thermostat

in

the reverse order.

Fig.

32. Central heating sensor.

Fl

ue

hood

fixi

ng

ho

ok

Loading...

Loading...