8. Domestic Hot Water

8.1 The following are general requirements

and

,

if

necessary,

ref-

erence should be made to the local Water Company before fitting

the

appliance.

8.2

MAINS

COLD

WATER

INLET.

Devices

capa

ble of preventing

the

flow of expansion water

must

not

be

fitted unless separate arrangements have been

made

.

An

expansion vessel can be fitted within the casing of the appliance

if

necessary.

An

RC

,/2 connection is provided on the flow switch assembl

y.

See

Fig. 38. A Zilmet

Z160 is the preferred type. A thread sealant com·

patible with potable water

must

be

used. ·

The final

600

mm

of

the

mains cold water connection to the appli·

ance

sh

ould

be

made in copper tube only.

The appliance

is

suitable for a mains supply having a maximum

pressure of

up

to 10

bar

(145 lb

./i

n.

2

).

A pressure reducing valve

must

be

fitted,

if

necessary.

The appliance is fitted with

an

isolating valve.

The

pump

, which circulates water to the domestic

hot

water

heat

exchanger, is

set

at maximum

and

must

not

be

adjusted.

8.3

HOT

WATER

SUPPLY

AND

FLOW

REGULATION

.

The minimum supply pressure

for

the maxi

mum

flow of hot water

is 1.3

bar

(20 lb

./

in

.

2

).

The maximum

hot

water flow rate

is

12.5

litres

/min.

( ± 15%) (2.8 gall

on

s/

min.) giving a temperature rise

of nominally

41

°

C.

The temperature rise of the domestic

hot

water

is

maintained by

the

automatic modulation of

the

heat input to the boiler.

The

temperature

of

the

incoming

water

is

raised

by a fixed

amount.

In

winter, when

the

ma

ins inlet temperature is lower, the

water flow

at

the

taps

must

be

reduced to maintain the required

delivery temperatur

e.

Ifthere are long pipe runs to the taps or shower then it is suggest·

ed

they

be

insulated to prevent the rapid cooling of residual

hot

water in

the

pipes after the

tap

or shower

has

been turned

off.

8.4

TAPS

AND

VALVES

.

Hot

and

cold

tap

s

and

mixing valves u

sed

with this

app

li

ance

must

be

suitable

for

operating

at

a mains pressure of up to 10

bar

(150 l

b./in.

2

).

8.5

SHOWERS

(FIXED

HEAD

TYPE).

No

anti-syphonage arrangements are necessary. Thermostatically

controlled shower valves

will

give extra comfort

and

guard against

the

flow of water

at

too high a temperature.

8.6

SHOWERS

(LOOSE

OR

FLEXIBLE

HEAD

TYPE)

.

A loo

se

h

ead

shower hose

must

be

fixed so

that

the

head ca

nn

ot

fall

closer

than

25 mm

(1

in

.)

above the top edge of the bath to pre·

vent

its immersion in

bath

water. Alternatively

the

shower

must

incorporate

or

be

fitted with

an

anti·syphonage device

at

the point

of

the

flexible hose connections.

Thermostatically controlled shower valves

will

give extra comfort

and

guard

aga

inst

the

flow of water

at

too high a temperature.

8.7

BIDETS.

The supply of

hot

and

cold mains water direct to a bidet is per·

mitted (subject

to

local Water Company requirements) provided

that

the

bidet is of the over·rim flushing type. The outlet(s) should

be

shrouded a

nd

unable to have

any

temporary

hand

held spray

attached.

No

anti·syphonage arrangements are necessary.

8.8

USE

IN

HARD

WATER

AREAS

.

As

the

maximum

temperature

of

th

e

domesti

c

hot

wa

ter

heat

exchanger is limited by

the

electronic control circuit, there is

nor

·

mally

no

need for water treatment to prevent scale accumulation.

In

exceptional circumstances a

de

vice capable of preventing scale

formation

can

be

fitted.

9

Installation of a scale inhibit

or

assem

bly

should

be

str

ictly in

accordance with the requirements of the local Water

Compan

y.

An

isolating valve

to

facilitate servicing should be incorporated.

The wa

ter

hardnes

s

ma

y

be

determined

using a

st

andard

test

paper

or

by reference to the local Water Compan

y.

Further infor·

mation

ma

y

be

obta

ined from Worcester Heat Sy

stems

Ltd.

9. Electrical

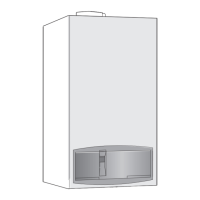

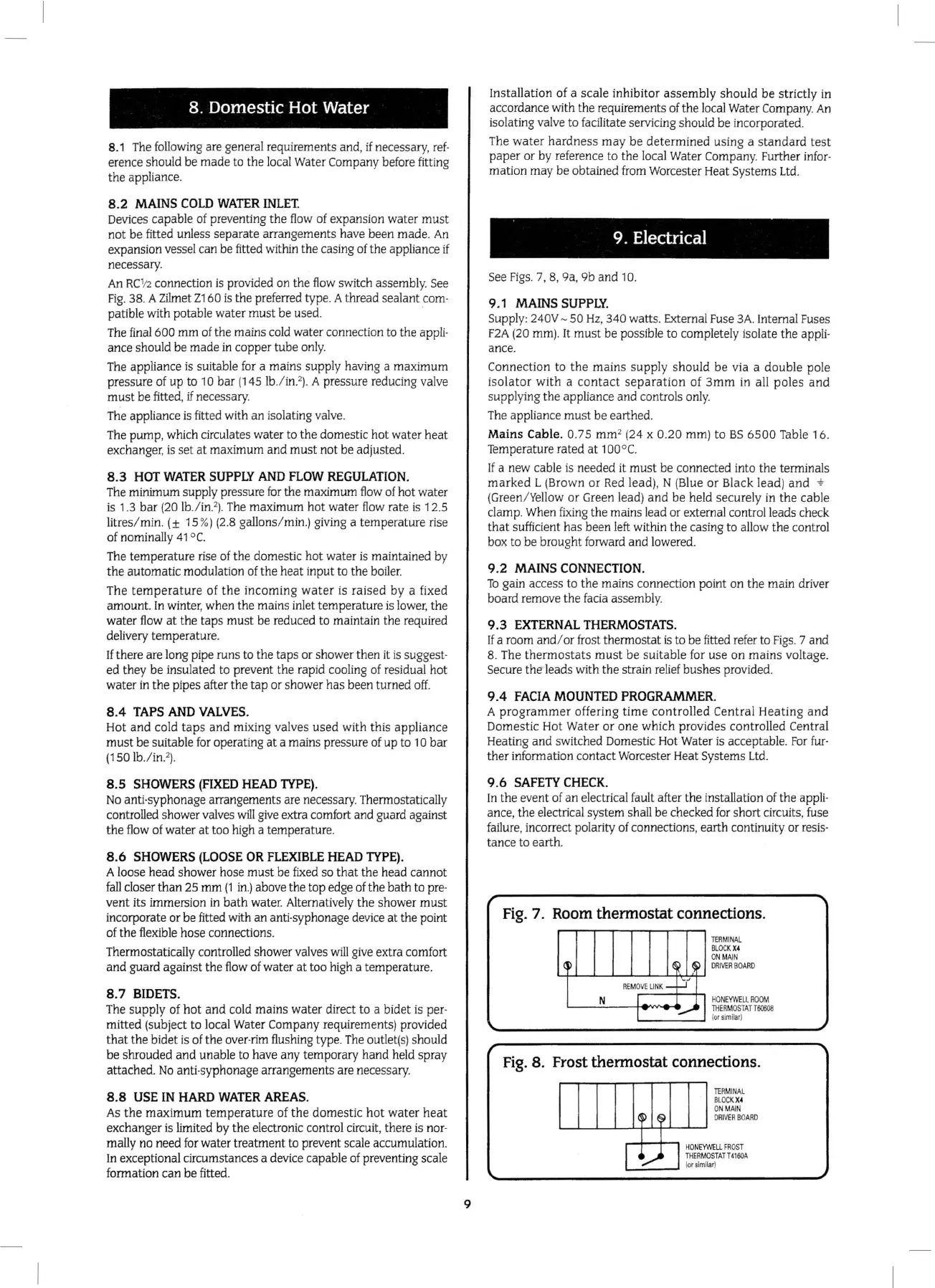

See

Figs.

7, 8, 9a,

9b

and 10.

9.1

MAIN

S

SUPPLY

.

Supply: 240V -

50

Hz,

340 watts. External Fuse

3A.

In

ternal Fuses

F2A

(

20

mm). It

must

be possible

to

completely isol

ate

the appli·

ance.

Connection to

the

mains

supply

should

be

via a double pole

isolato

r

with

a

contact

sepa

ration

of

3mm

in all

poles

and

supplying the appliance and controls

only.

The

app

liance

must

be

earthed.

Mains Cable. 0.75

mm

2

(24 x

0.20

mm

) to

BS

65

00

Table 16.

Temperature rated

at

100

°C.

If

a new cable is needed it

mus

t

be

connected into the terminals

marked

L (Brown

or

Red lead), N (Blue

or

B

lack

lead)

and

~

(Green/

Yellow

or

Green lead)

and

be

held securely in

the

cable

clamp. When fixing the mains lead or external control leads check

that

suffici

ent

has

been left within the casing to allow

the

control

box to

be

brought forward

and

lowered.

9.2

MAINS

CONNECTION

.

To

gain access to

the

mains connection point

on

the main driver

board remove

th

e facia assembly.

9.3

EXTERNAL

THERMOSTATS.

If

a room and/ or frost thermostat is to

be

fi

tted refer to

Figs

. 7 and

8. The

the

rm

ostats

must

be

suitable for use

on

mains

voltage.

Secure

t

he

leads with the strain relief bushes provided.

9.4

FACI

A

MOUNTED

PROGRAMMER.

A

programmer

offeri

ng

time

controlled

Cen

tral

Heatin

g

and

Domestic Hot Water

or

one

which provides c

ont

rolled Central

Heating

and

switched Domest

ic

Hot

Wa

t

er

is

acceptable.

For

fur·

ther

information contact Worcester Heat Syst

ems

Ltd.

9.6

SAFETY

CHECK.

In

the event of

an

electrical

fa

ult after the ins

ta

llation of

the

appli·

ance, the electrical system

sha

ll

be

checked

for

sho

rt

circuits, fuse

failure, incorrect polarity of connections, earth continuity or resis·

tan

ce to earth.

Fig.

7. Room thermostat connections.

(p

I

~

~

RE

M

OVE

LINK

-

.:/

N

I

•..,....-A

I

TERM

I

NA

L

BLOC

K

X4

ON

MA

IN

DR

I

VER

BOARD

HO

NEYWE

LL

ROO

M

TH

ERM

OSTATT60608

l

or

si

mil

a

r)

Fig

. 8. Frost thermostat connections.

TER

MI

NA

L

BLOCK

X4

ON

MAIN

~

~~

D

RIVER

BOARD

r

I

HONEYWELL

FROS

T

...........

THER

MOSTATT4

160A

(or

s

imilar)

Loading...

Loading...