5. Flue Terminal Position

See

Fig

. 4.

5.1 The flue m

ust

be installed

as

specifi

ed

by

BS

5440

: Part 1.

5.2

T

he

standard

fl

ue l

ength

is

100

mm

(4

in.)

up

to

1000

mm

(39.3 in.). The

extended

flue length is 1001 mm (39.4 in.)

up

to

20

00

mm

(78.7 in.

).

5.3 The air

du

ct should

be

supported

at

the

joint of

the

extended

duct

and

the

brackets rigidly fixed to

the

wall.

5.4

The

termina

l

must

be

positioned

so

as

not

to

cause

an

obstruction

and

so

that

the

combustion products do

not

cause a

nuisance.

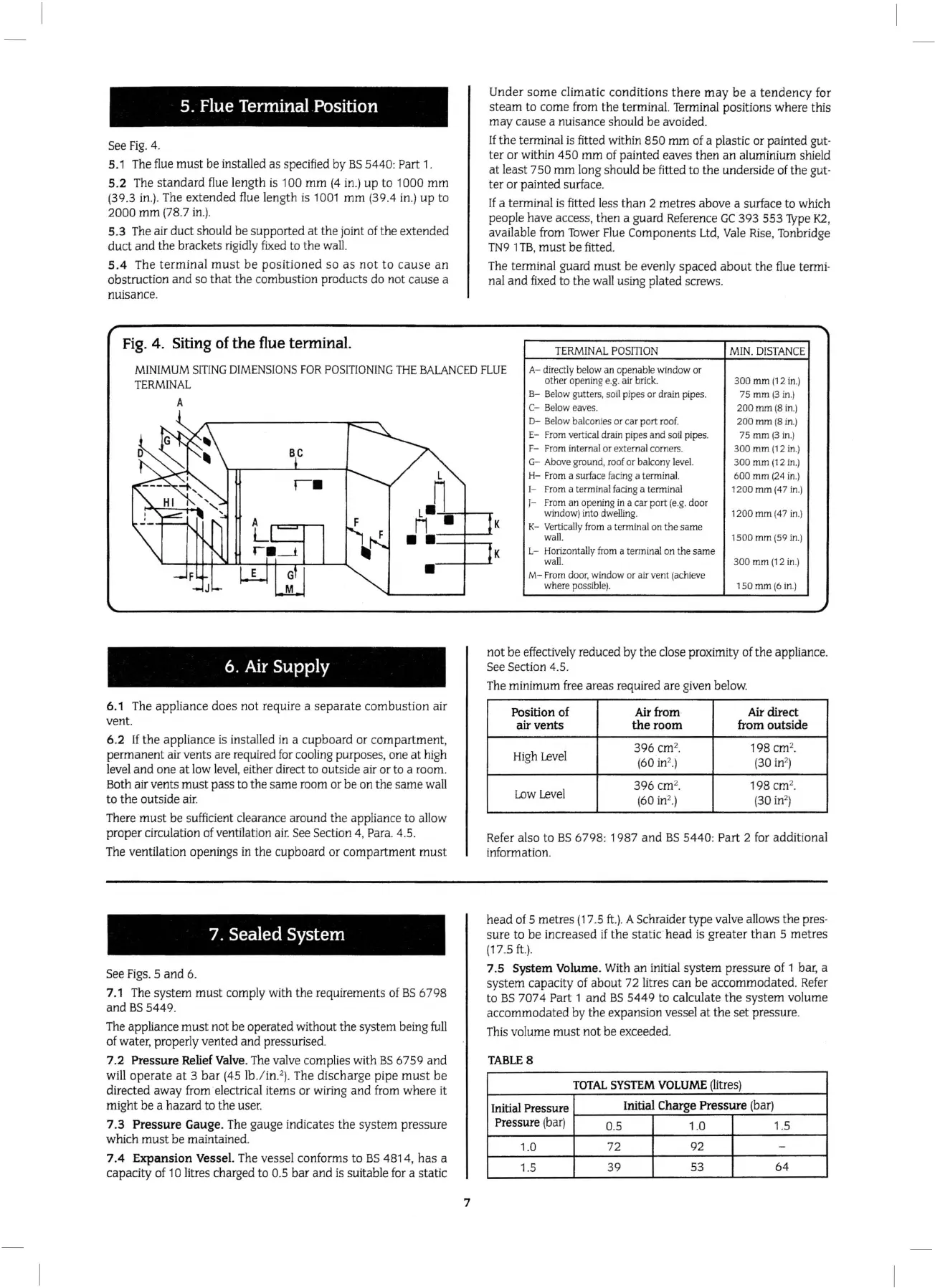

Fig.

4.

Siting of

the

flue terminal.

Under

some

climatic

conditions

th

ere

may

be

a t

endency

for

steam

to

come

from

the

terminal. Terminal positio

ns

where this

ma

y

cause

a nuisance should

be

avoided.

If

the

terminal is fitted within 850

mm

of a plastic

or

painted gut-

ter

or within

450

mm

of painted eaves

then

an

alumini

um

shield

at

least 7 50

mm

long should be fitted

to

the

undersi

de

of

the

gut-

ter

or pai

nt

ed surface.

If

a terminal is fitted less

than

2 metres above a surface to which

people have access,

the

n a guard Reference

GC

393

553

Type

K2

,

available from Tower Flue Components Ltd,

Va

le Rise, Tonbridge

TN9

1TB,

must

be

fitted.

The term

in

al guard

mu

st

be

evenly

spaced

about

the

flue termi-

nal

and

fixed

to

the

wa

ll

using plated screws.

TERMIN

AL

P

OSITI

ON

MI

N.

DI

ST

ANCE

MINIMUM

S!TING

DIMENS

I

ONS

FOR

P

OSITIONING

THE

BALANCED

FLUE

TERMINAL

A- directly bel

ow

an openable

wind

ow

or

other opening e.

g.

air

brick.

300

mm (1 2

in

.)

A

6.

Air

Supply

6.1 The appliance

does

not

require a

sepa

r

ate

combu

st

ion air

vent

.

6.2

If

the

app

li

ance is

in

stalled

in

a cupboard or co

mpartment,

permanent

air vents are required

fo

r coo

li

ng purposes, one

at

high

level

and

one

at

low level, either direct to outside air

or

to

a room.

B

ot

h air ve

nts

must

pass to

the

same

room

or

be

on the same wall

to

the

outside air.

There

must

be

sufficient clearance around

the

appliance to allow

proper

circulation of ventilation air. See Section 4, Para. 4.

5.

The ventilation openings

in

the

cupboard

or

co

mp

art

ment

mu

st

7. Sealed System

See Figs. 5

and

6.

7.1 T

he

system

must

comply with

th

e requirements of

BS

6

798

and BS 5

449

.

The appliance

must

not

be operated without

the

sys

tem

being

full

of

wa

ter, properly vented

and

pressuri

se

d.

7.2 Pr

ess

ur

e Relief Valve. The valve complies with

BS

6759 and

will

operate

at

3

bar

(45 lb

./

in

2

).

The di

sc

har

ge pipe

must

be

directed away from electrical items or wiring a

nd

from where it

might

be

a hazard to

th

e

us

e

r.

7.3

Pressure

Gauge. The

gauge

indicates

the

system

pressure

which

must

be maintained.

7.4 E

xpansion

Vessel. The vessel conforms

to

BS

48

14,

has

a

capacity of

10 litres charged

to

0.5

bar

and

is suitable for a static

7

B-

Below g

ut

ters, soil pipes

or

drain pipes.

75

mm(3

in

.)

C-

Be

l

ow

eaves.

200

mm

(8 in.)

0-

Bel

ow

balconies or car

port

roof.

200

mm

(8

in.)

E- From vertical drain pipes and soil pipes.

75

mm

(3

in.)

F-

From

intern

al

or

external comers.

300

mm

(12

in

.)

G-

Above ground,

roof

or

ba

l

cony

level.

300

mm

(1 2

in

.)

H-

From a surface facing a te

rmi

nal.

600

mm

(24 in.)

1-

Fr

om

a terminal fadng a terminal

1200

mm

(47 in.)

J-

From an opening in a car

port

(e.g.

door

wi

ndow

)

in

to dwelling.

1200

mm (47

in

.)

K- Vertically from a terminal

on

the same

wall.

1500

mm

(59

in

.)

L- Horizontally from a terminal on

the

same

wall.

300

mm (12

in

.)

M- From

door

.

window

or

air

vent (achieve

where possible). 1

so

mm

(6

in

.)

not

be

effectively reduced

by

the

close proximi

ty

of the appliance.

See Section 4.5.

The minim

um

free ar

eas

required are given below.

Position of

Ai

r from

Air

dir

ect

air

vents

the

room

from

ou

ts

ide

High

Level

396

cm

2

•

198 cm

2

•

(6

0in

2

)

(30

in

2

)

Low

Level

396

cm

2

.

198 cm

2

•

(6

0 in

2

.)

(

30

in

2

)

Refer also

to

BS

6798

: 1987

and

BS

5440: Part 2 for

addit

ional

inf

ormat

ion.

head

of 5 metres (17 .5

ft

.).

A Schraider

type

valve allo

ws

the

pres-

sure

to

be

increa

sed

if

the

static

head

is

grea

t

er

th

an

5 metres

(17.5

ft

.).

7.5

S

ys

tem

Vol

ume

. With

an

initial

system

pressure of 1 bar, a

sys

tem capacity of about 72 litres can

be

acc

omm

od

ated

. Refer

to

BS

7

07

4 Part 1 a

nd

BS

544

9

to

calcula

te

the

system

volume

accom

modated

by

the

expa

ns

ion vessel

at

the

se

t pressure.

This vol

ume

must

not

be

exceeded.

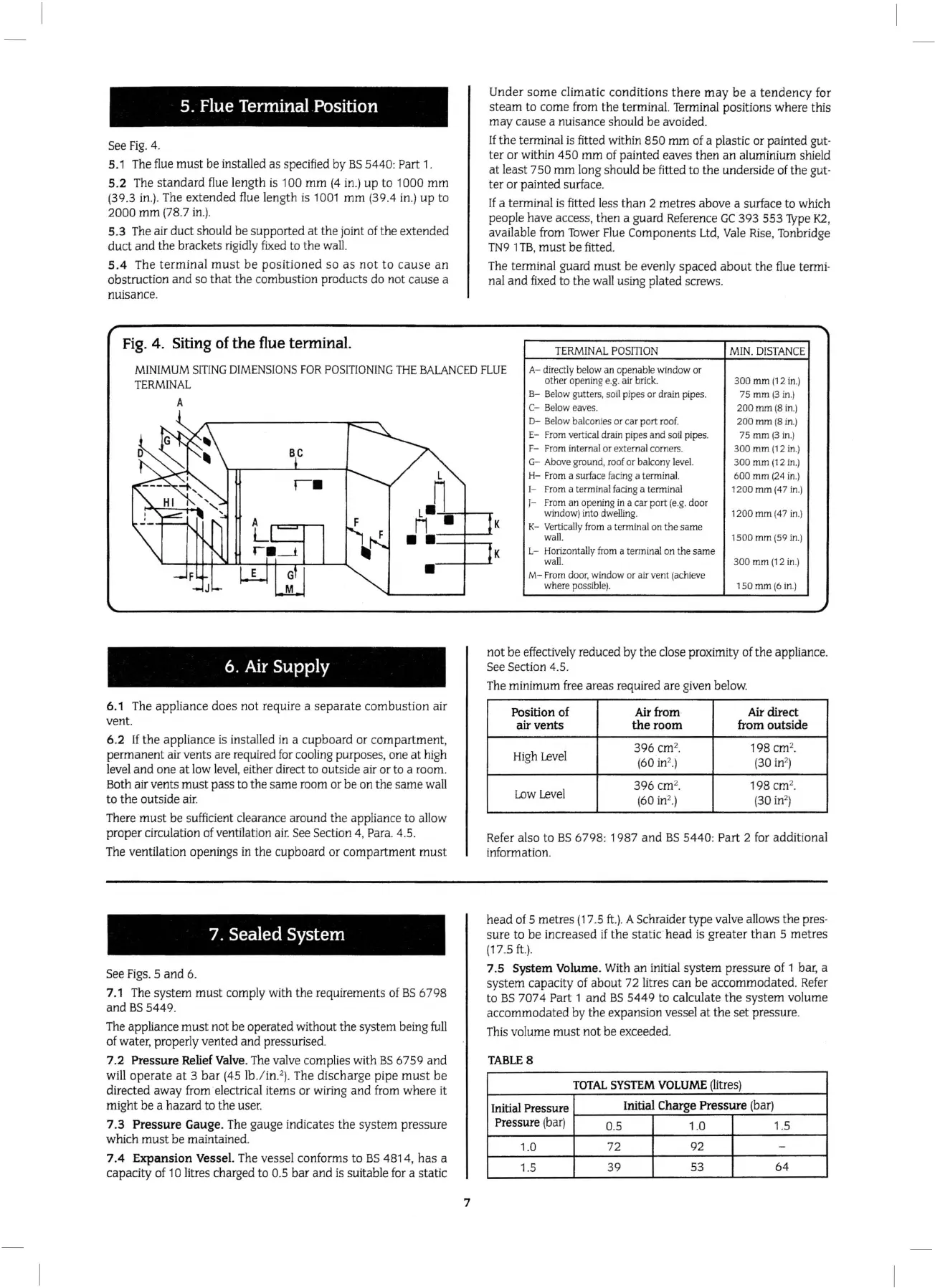

T

AB

L

ES

TO

TAL

SYSTE

M

VOLUM

E (litres)

Initial Press

ure

Initial Ch

arge

Pressure

(bar)

Press

ur

e

(bar)

0.5 1.0

1.5

1.0

72

92 -

1.5

39

53

64

Loading...

Loading...