8

1-4-2. Product installation and use environment

1. Installation requirement

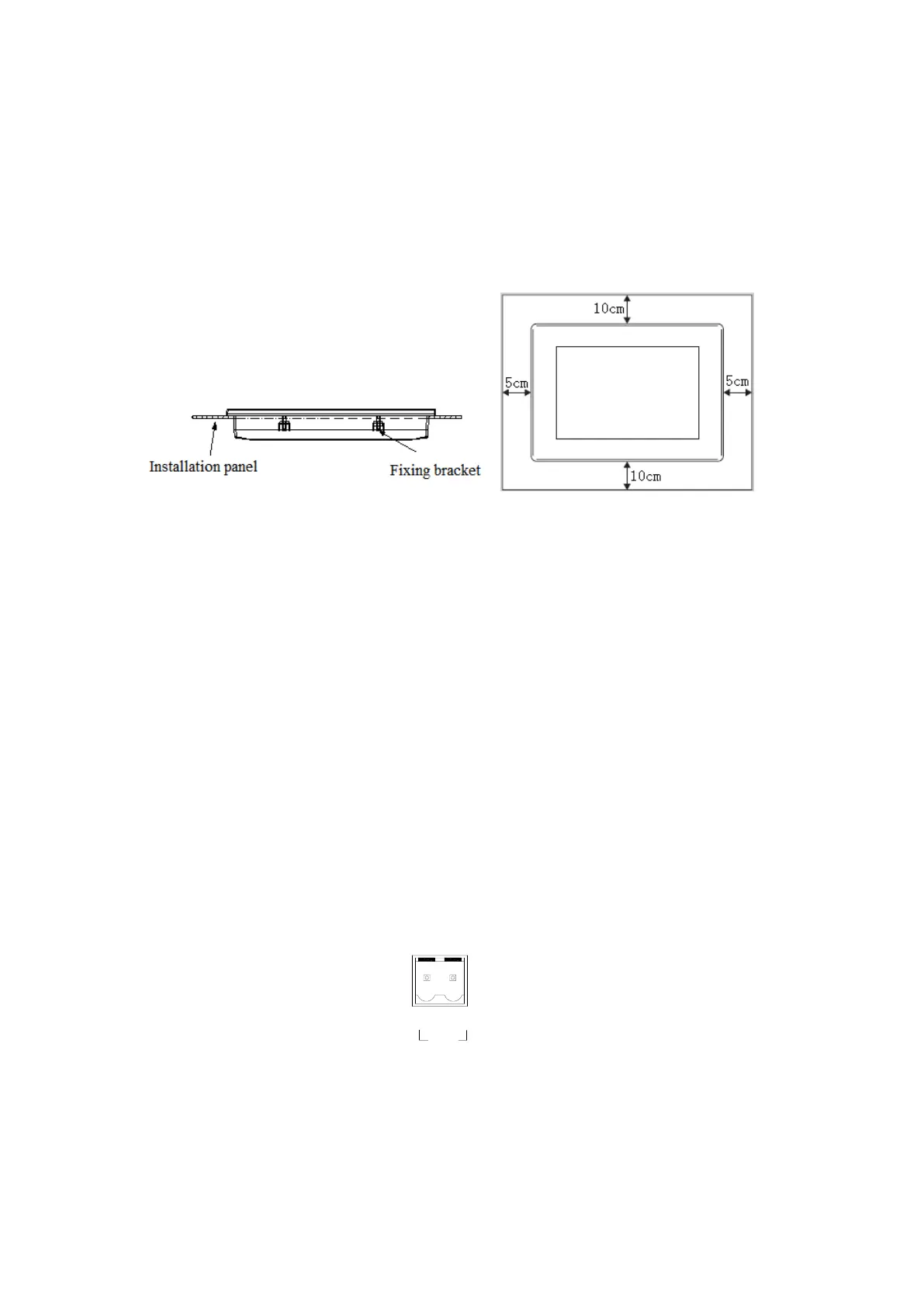

TS3 series HMI is equipped with four iron mounting brackets at the factory. The upper and lower sides of the

display are respectively provided with two square fixing holes. The display is tightly fixed to the mounting holes

of the control cabinet with the mounting bracket.

In order not to cause the temperature of the HMI to be too high when working for a long time, it is better to

reserve 10cm space above and below the HMI and 5cm space left and right during installation to ensure smooth

air convection.

2. Installation steps

(1) According to the dimensions in the previous section, open a rectangular mounting hole on the panel of the

control cabinet.

(2) During installation, a sealing ring is added in the sealing groove.

(3) Insert the bottom of the display into the mounting hole of the control cabinet.

(4) Insert the mounting bracket into the side fixing hole of the display and tighten the screws.

(5) Connect the HMI and PLC communication port with communication cable.

The communication cable can be provided by the manufacturer or processed by the user according to the

connection diagram, and can start to work after being connected to the +24V DC power supply.

3. Environmental factor

Please install and use correctly within the specified environment.

【Note】: Do not use it in a dangerous environment full of flammable gas, water vapor or dust, and do not install it in an

environment where the temperature changes too fast or the humidity is high, otherwise it will cause moisture

condensation inside the HMI.

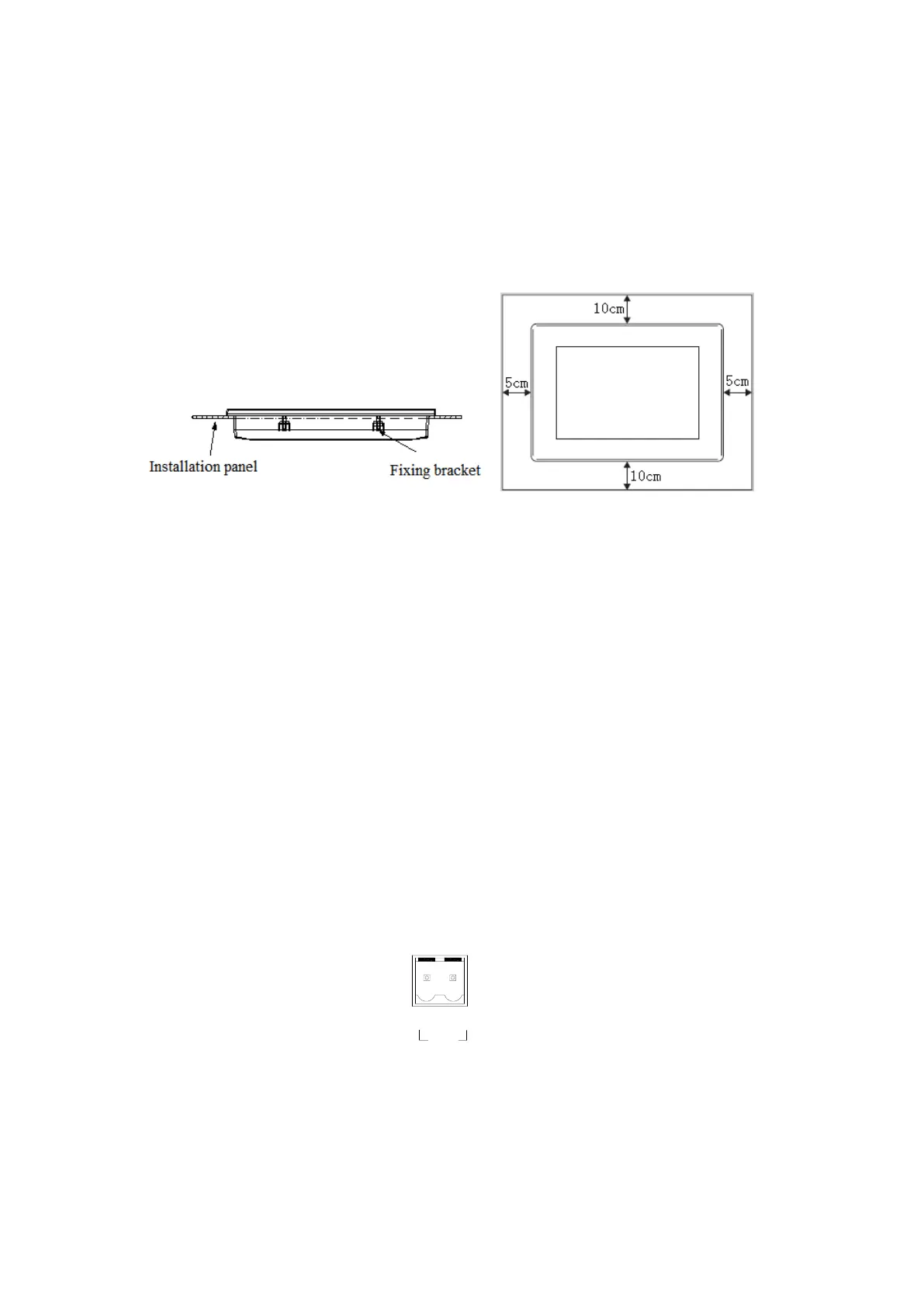

4. Power supply requirement

TS3 series HMI can only use DC power supply. The power supply specification is DC+24V (voltage range:

22V~26V), which conforms to the standard of DC power supply for most industrial control equipment. Connect

the positive pole of the DC power supply to the "+24V" terminal and the negative pole of the DC power supply to

the "0V" terminal. As shown in the figure below:

In addition, connecting high voltage or alternating current to the power input terminal in the HMI will make the

equipment unusable and may cause electric shock to the human body. Such mistakes or serious electric shock can

lead to personal injury, even death, and equipment damage.

【Note】:

If the PLC DC output is used to drive the HMI, it must be considered that the +24V DC output of some controllers may

not have enough current to support it.

Loading...

Loading...