6.2 Torque values

All screws and nuts must be lubricated to achieve correct tightening torque. Screws that

are screwed into stainless steel must have the threads coated with suitable lubricants to

prevent seizing.

If there is a question regarding the tightening torques, then contact a sales or authorized

service representative.

Screws and nuts

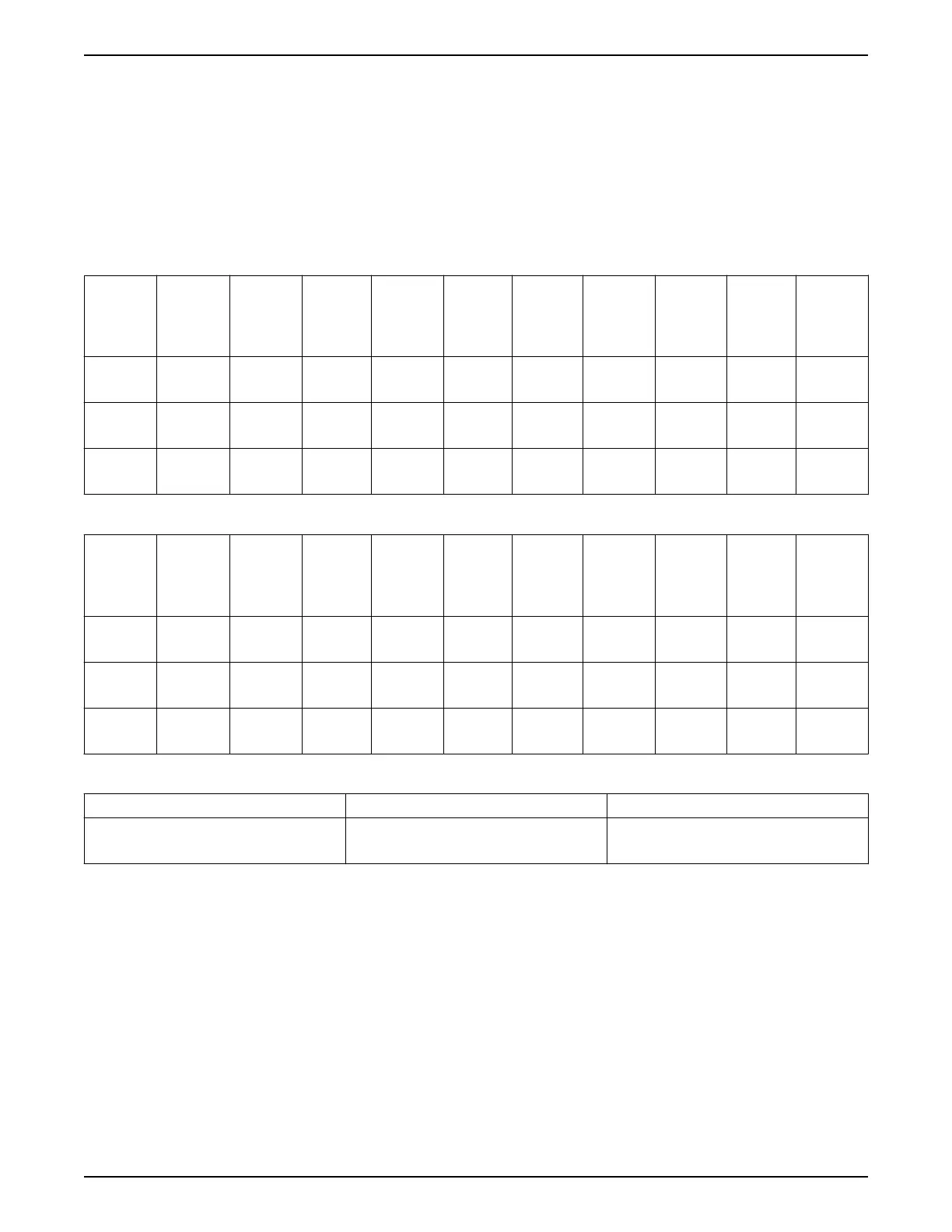

Table 1: Stainless steel, A2 and A4, torque Nm (ft-lbs)

Property class

M4 M5 M6 M8 M10 M12 M16 M20 M24 M30

50 1.0

(0.74)

2.0

(1.5)

3.0

(2.2)

8.0

(5.9)

15

(11)

27

(20)

65

(48)

127

(93.7)

220

(162)

434

(320)

70, 80 2.7

(2)

5.4

(4)

9.0

(6.6)

22

(16)

44

(32)

76

(56)

187

(138)

364

(268)

629

(464)

1240

(915)

100 4.1

(3)

8.1

(6)

14

(10)

34

(25)

66

(49)

115

(84.8)

248

(183)

481

(355)

— —

Table 2: Steel, torque Nm (ft-lbs)

Property class

M4 M5 M6 M8 M10 M12 M16 M20 M24 M30

8.8 2.9

(2.1)

5.7

(4.2)

9.8

(7.2)

24

(18)

47

(35)

81

(60)

194

(143)

385

(285)

665

(490)

1310

(966.2)

10.9 4.0

(2.9)

8.1

(6)

14

(10)

33

(24)

65

(48)

114

(84)

277

(204)

541

(399)

935

(689)

1840

(1357)

12.9 4.9

(3.6)

9.7

(7.2)

17

(13)

40

(30)

79

(58)

136

(100)

333

(245)

649

(480)

1120

(825.1)

2210

(1630)

Table 3: Brass, torque Nm (ft-lbs)

M5 M8 M10

2.7 (2.0) 11

(8.1)

22

(16.2)

Hexagon screws with countersunk heads

For hexagon socket head screws with countersunk head, maximum torque for all property

classes must be 80% of the values for property class 8.8 above.

6.3 Change the oil

This image shows the plugs that are used to change the oil.

6 Maintenance

44 Flygt 3102 Installation, Operation, and Maintenance Manual

Loading...

Loading...